Digital capacitance type liquid level measuring sensor

A liquid level measurement and capacitive technology, which is applied in the field of digital capacitive liquid level measurement sensors, can solve the problems of short service life, inaccurate readings, large reading errors, etc., and achieve the effect of long service life and accurate readings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

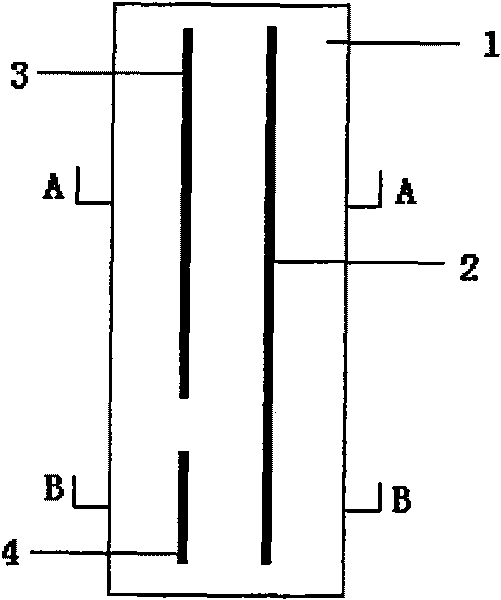

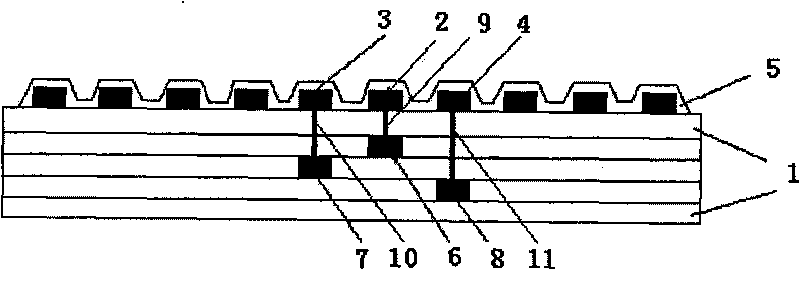

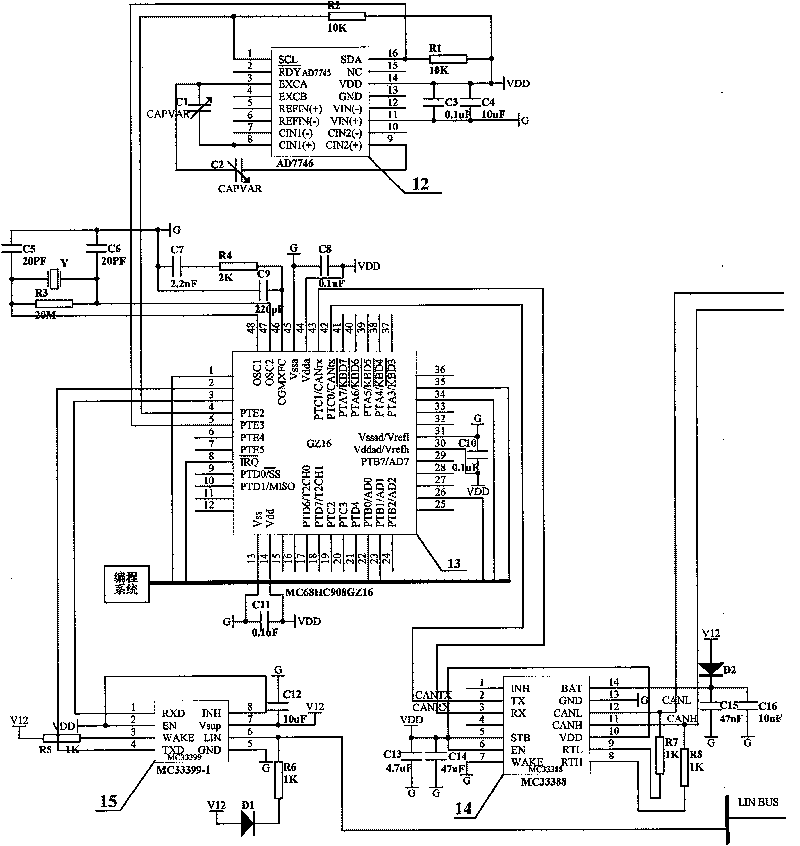

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] Capacitive liquid level sensor is the application of the capacitance value and the electrode's facing area, spacing and the dielectric constant of the medium between the electrodes. When two of the quantities are kept unchanged and the third quantity is changed, the capacitance value changes accordingly. This principle is realized. With the maturity of microelectromechanical system (MEMS) processing technology, we can make capacitive electrodes on silicon substrates, which can form large-scale arrays, obtain high-precision, low-energy sensors, and reduce costs. , more suitable for mass production.

[0023] The invention provides a novel digital capacitive liquid level measurement sensor based on MEMS technology, which can be used for the liquid level measurement of automobile fuel tanks, and can also be used in the fields of chemical industry, petroleum, water l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com