Hydraulic ceramic brick press and method for prolonging service life of hydraulic oil

A ceramic tile press and hydraulic oil technology, applied in the field of hydraulic equipment, can solve the problems of no one trying to prolong the service life of the hydraulic oil of the tile press, capital consumption, and no one paying attention to the problem of capital consumption of ceramic tile presses, etc., to achieve easy The effects of promotion and implementation, reduction of replacement frequency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

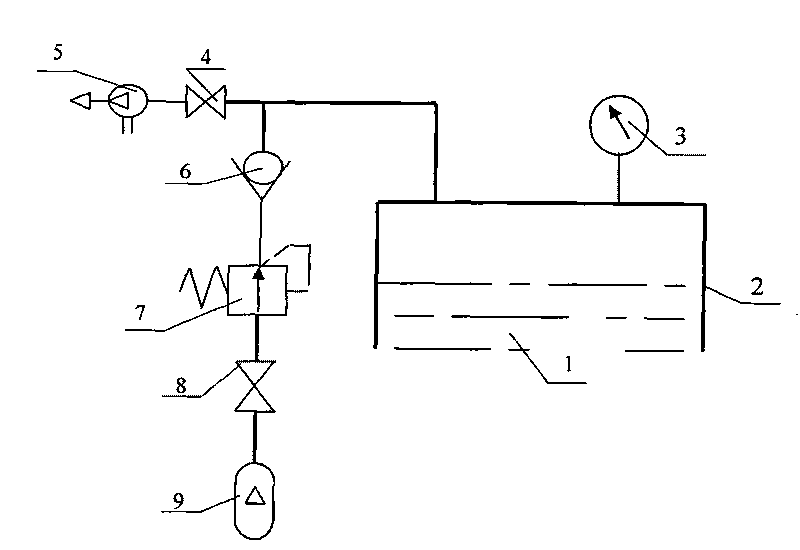

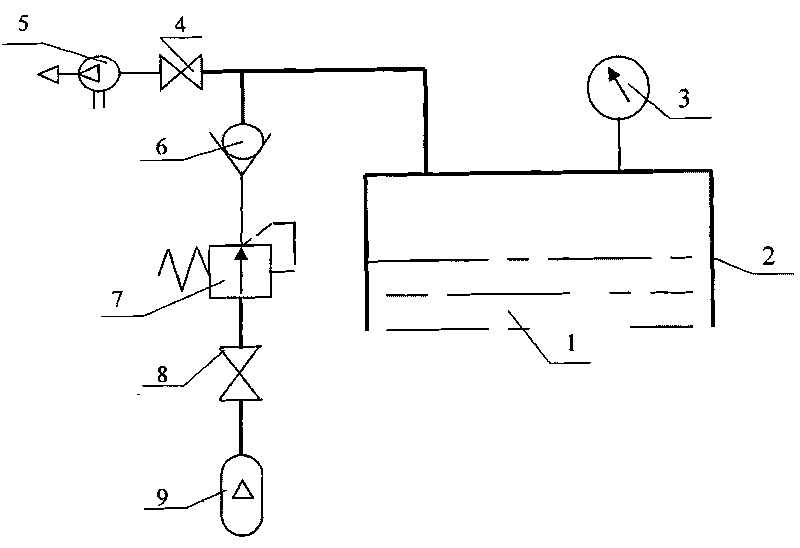

[0008] see figure 1 , The hydraulic ceramic tile press of the present invention includes a liquid-filled oil tank 2 for storing hydraulic oil 1, and the liquid-filled oil tank is connected to a compressed nitrogen source 9 and a vacuum device 5 through a pipeline. The compressed nitrogen source 9 and the vacuum device 5 can be connected in parallel with the liquid-filled oil tank 2 as shown in the figure, or can be connected with the liquid-filled oil tank with independent pipelines. The source of compressed nitrogen can be bottled compressed nitrogen or bottled liquefied nitrogen. Vacuuming equipment can adopt reciprocating vacuum pump or vane vacuum pump. Compressed nitrogen is piped into the liquid-filled tank. The nitrogen pressure in the liquid-filled oil tank is greater than the atmospheric pressure, so as to block the air from entering the liquid-filled oil tank, and make the pressure in the liquid-filled oil tank meet the working requirements.

[0009] As a further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com