Microcomputer liquid vacuum filling machine and control system

A vacuum perfusion and microcomputer technology, applied in printing and other directions, can solve problems such as unsatisfactory implementation effects, and achieve the effects of facilitating performance appraisal and financial management, easy ink filling work, and intuitive, simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

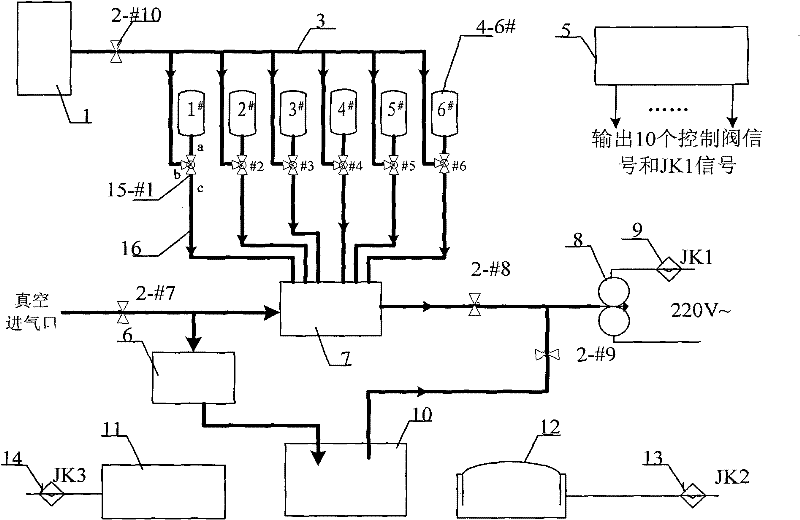

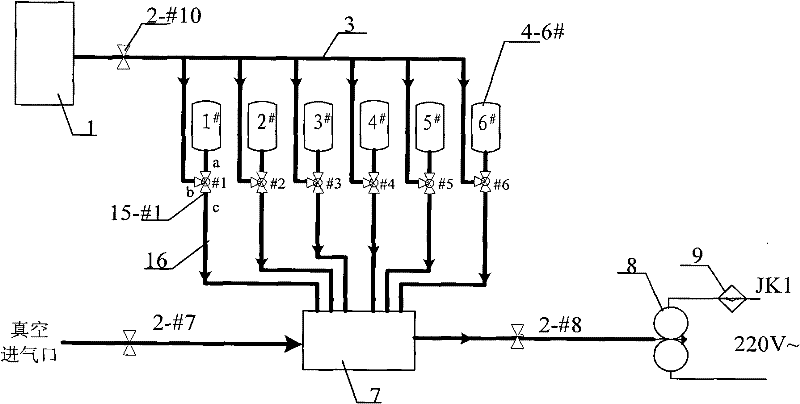

[0022] Embodiment 1: It includes an ink filling device, a device for cleaning residual ink before filling ink, a device for cleaning ink cartridges after filling ink, a device for cleaning ink filling pipelines, an automatic control device and a service management device;

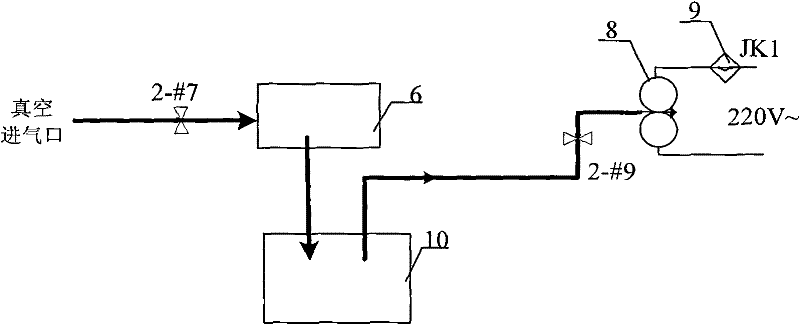

[0023] In the ink filling device, 6 liquid bottles 4 (4-1#, 4-2#, 4-3#, 4-4#, 4-5#, 4-6#), 6 three-way control valves 15 ( 15-#1, 15-#2, 15-#3, 15-#4, 15-#5, 15-#6), 6 ink filling pipelines 16 are respectively connected with the filling in the ink box to be filled in the filling cylinder 7 The ink hole is connected, one side of the filling cylinder 7 is connected to the vacuum inlet through the control valve 2-#7 and the pipeline 3, and the other side is connected to the vacuum pump 8 through the control valve 2-#8 and the pipeline 3; In the ink cleaning device, one side of the liquid pumping cylinder 6 is connected with the vacuum air inlet through the control valve 2-#7 and the pipeline 3, and the other s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com