Water jacket and water pressure test device applying same

A technology of water jacket and water jacket cover, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of low production efficiency, easy damage, and difficult discharge of air bubbles, and achieve high production efficiency , stable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

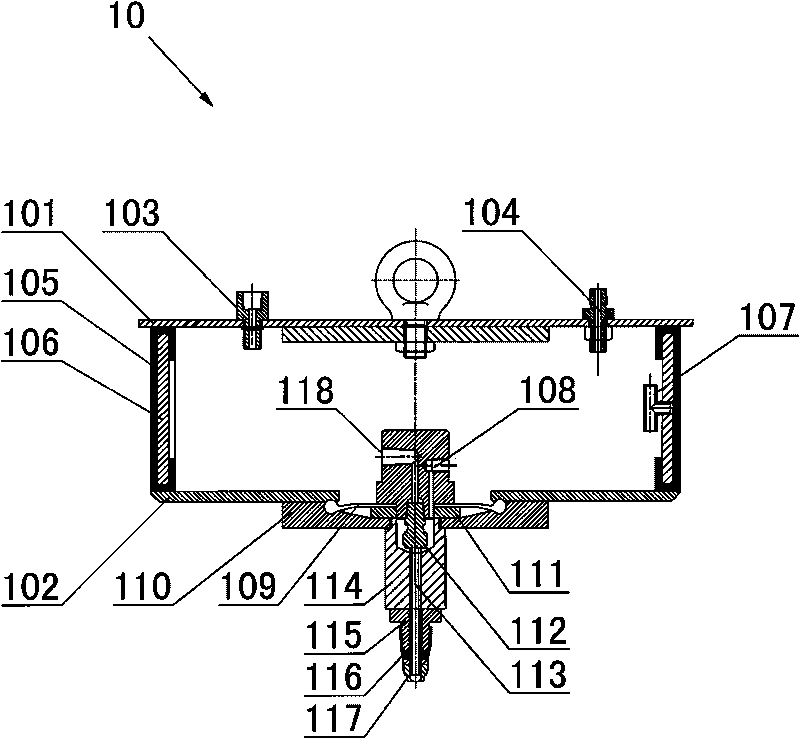

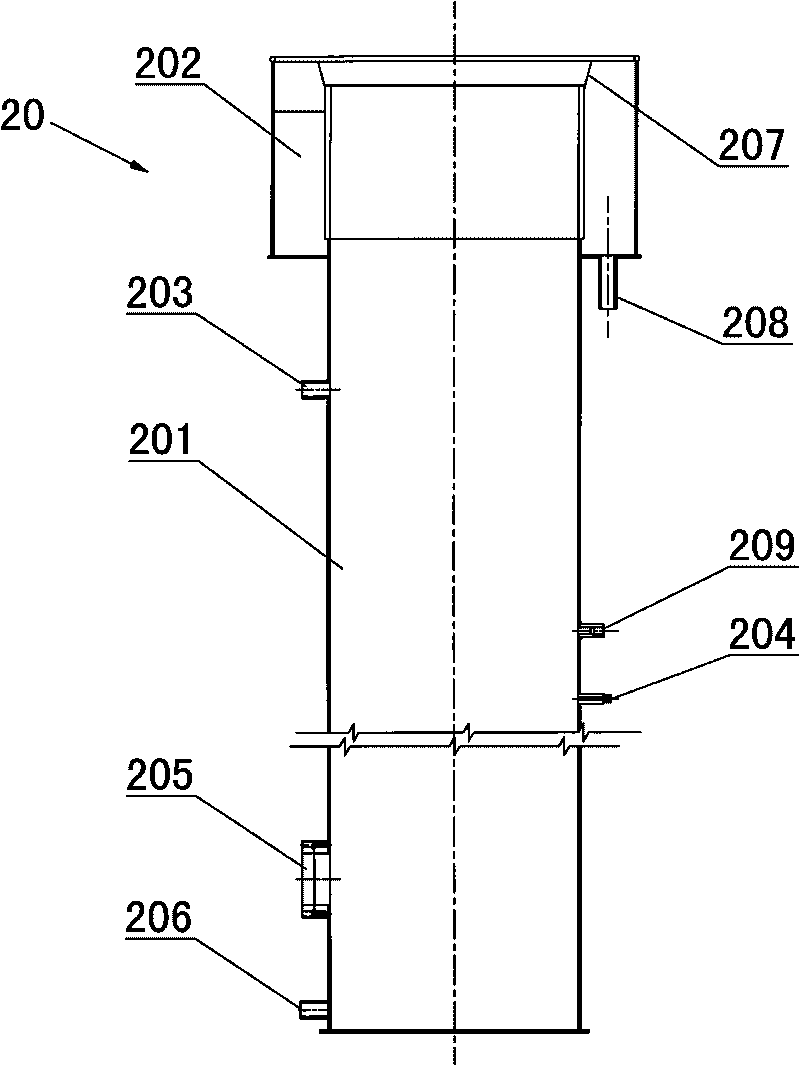

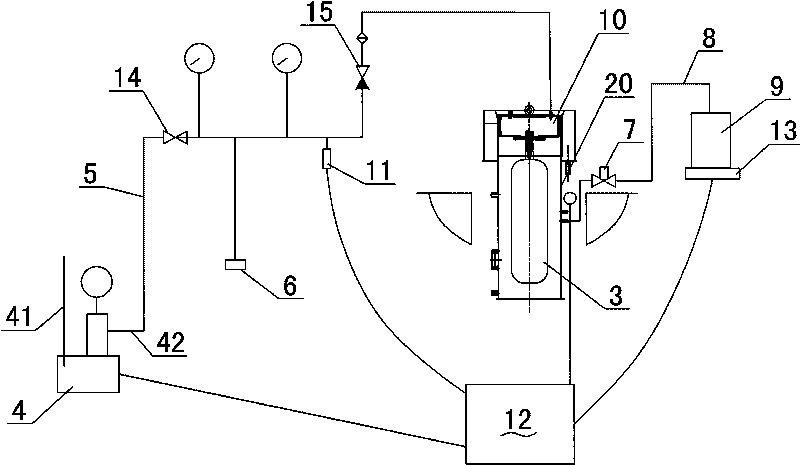

[0019] The invention discloses a water jacket, which includes water jacket covers ( figure 1 ) and water jacket ( figure 2 ).

[0020] Such as figure 1 As shown, the water jacket cover 10 includes an upper cover 101 and a lower cover 102 fixed to each other by screws. The upper cover 101 is provided with a pneumatic joint 103 for connecting a compressed air pipeline, a high-pressure joint 104 for connecting a high-pressure water pipeline, and a lifting ring for hoisting. A C-shaped sealing sleeve 105 is arranged in the ring between the upper cover 101 and the lower cover 102 of the water jacket cover 10, and a rigid limit sleeve 106 is arranged on the inner side of the C-shaped seal sleeve 105. The sleeve 106, the upper cover 101 and the lower cover 102 exert a clamping force on both ends of the C-shaped sealing sleeve 105, so that the two ends of the C-shaped sealing sleeve 105 are clamped.

[0021] The limiting sleeve 106 is provided with a pneumatic tee 107, and the pn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com