Local reverse-coupling toroidal inductor

A ring inductor, reverse coupling technology, applied in the direction of transformer/inductor core, inductor/transformer/magnet manufacturing, transformer/inductor coil/winding/connection, etc., can solve electromagnetic interference and radio frequency interference pollution, filtering Problems such as large inductance value and high noise can achieve the effects of reducing manufacturing cost and operating energy consumption, reducing volume and weight, and reducing ripple current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

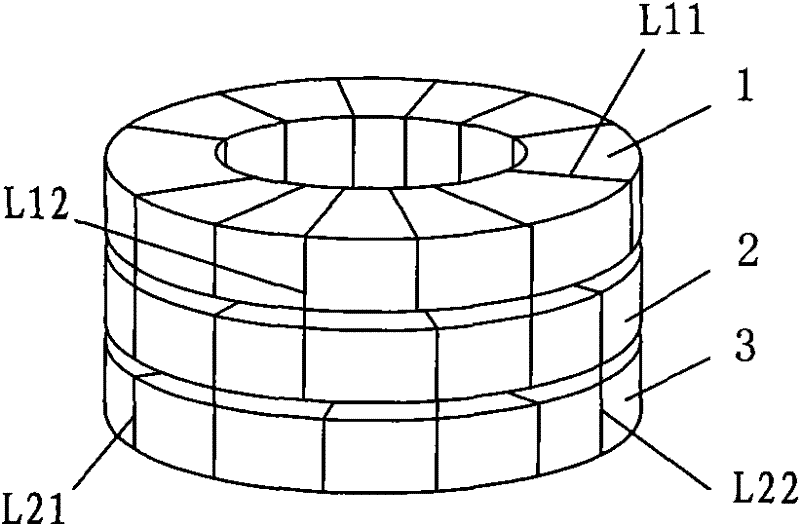

[0024] figure 1 It is a three-dimensional schematic diagram of the first embodiment of the present invention. It can be seen from the figure that the present invention includes a ring-shaped iron core. The top iron core 1 and the bottom iron core 3; the top coil L1 and the bottom coil L2 are respectively wound on the three-layer iron core.

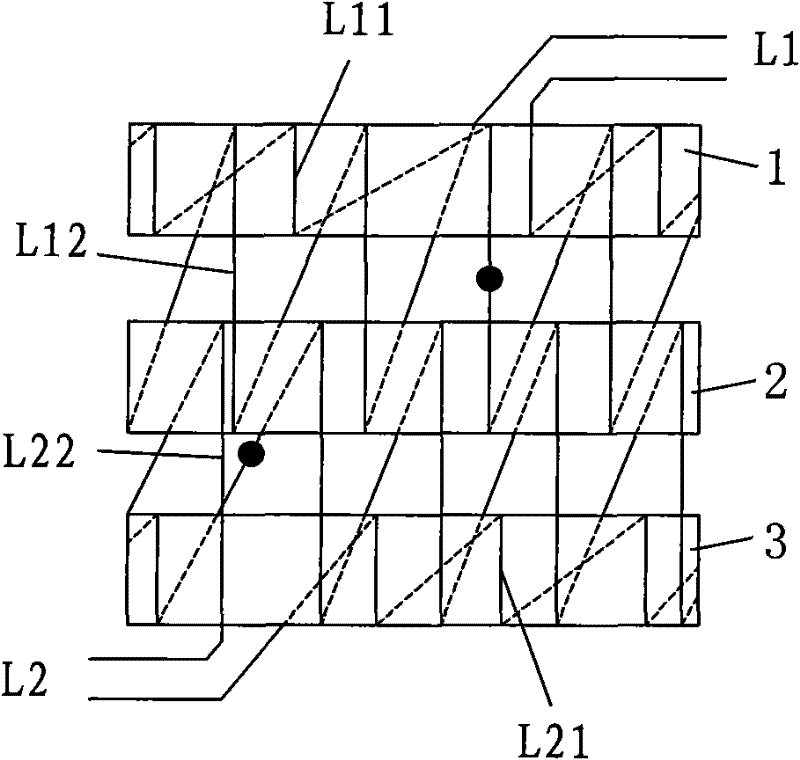

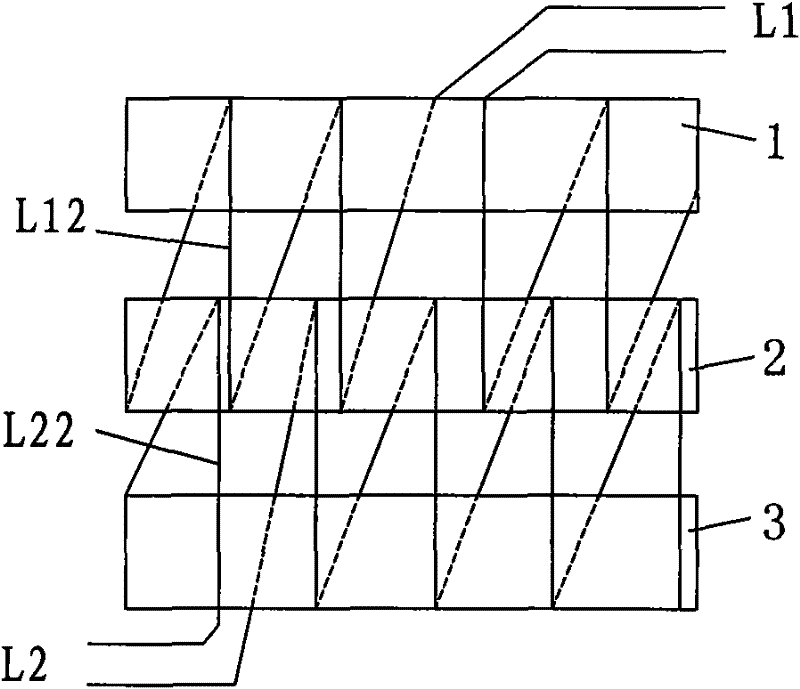

[0025] figure 2 It is a structural schematic diagram of the first embodiment of the present invention. It can be seen from the figure that the top coil L1 of the first embodiment includes: a top coil short winding L11 uniformly surrounding the top iron core 1, and a top coil winding L11 uniformly surrounding the top iron core 1 in series. The long winding L12 of the top coil on the core 1 and the middle core 2; the bottom coil L2 includes the short winding L21 of the bottom coil uniformly surrounding the bottom core 3, and the short winding L21 of the bottom coil evenly surrounding the bottom core 3 and the middle core 2 in series The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com