Fully automatic cleaning equipment of bean sprout transfer container

A technology for cleaning equipment and turnover boxes, applied in the field of mechanical equipment, can solve the problems of reducing the service life of the turnover box, aging of the plastic frame of the turnover box, increasing the labor intensity of workers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

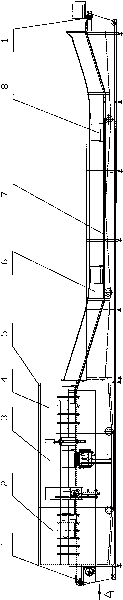

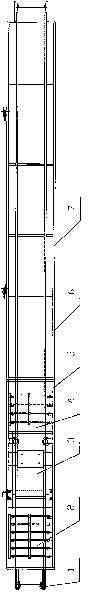

[0033] Depend on figure 1 , figure 2 It can be seen from the schematic diagram of the overall structure of the automatic bean sprouts turnover box cleaning equipment of the present invention that it includes a soaking box 6 and a cleaning box 5 connected together, and the cleaning box 5 is sequentially provided with high-pressure water washing devices from right to left 4. The brush cleaning device 3 and the clean water rinsing device 2 , the high-pressure water rinsing device 4 is located on the side close to the soaking tank 6 . The transmission mechanism 1 is installed on the cleaning box 5 and the soaking box 6, and the inner wall of the cleaning box 5 and the soaking box 6 is connected with a guide rail 7. Bean sprouts turnover case 8 just slides on guide rail 7.

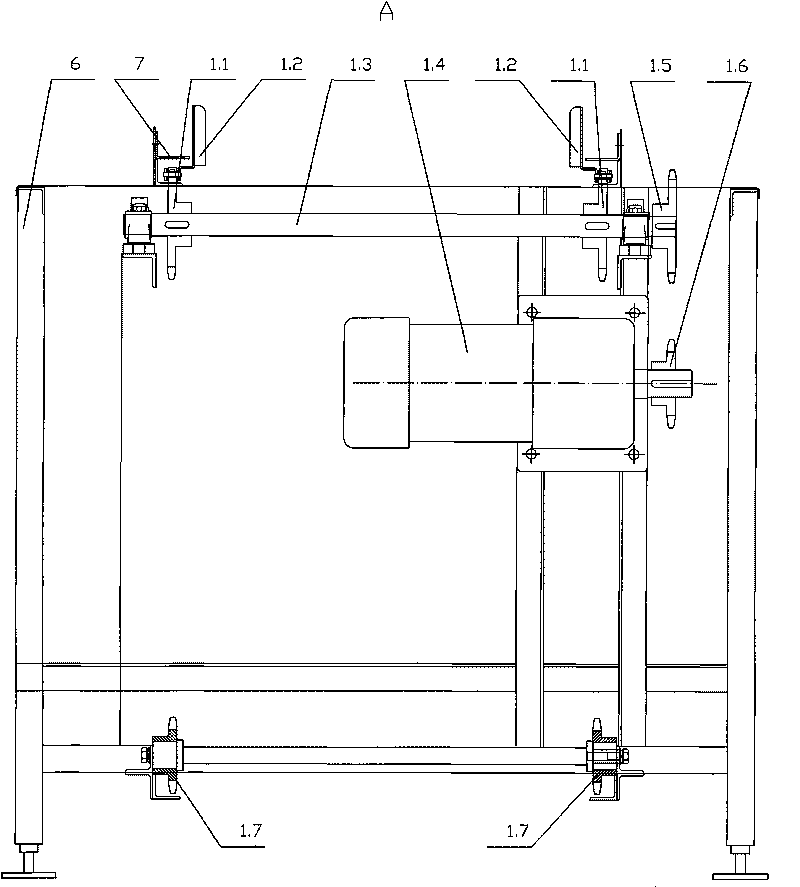

[0034] Depend on image 3 , Figure 4 As can be seen from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com