Backlight module, plat panel display and design method of positioning element of flat panel display

A technology for backlight modules and positioning components, which is applied to optical components, light source fixing, instruments, etc., can solve the problem of uneven brightness in the visible area, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

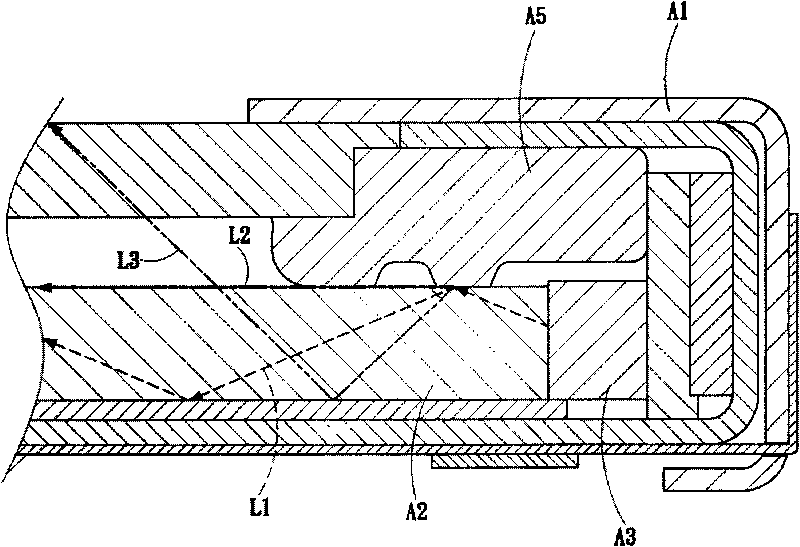

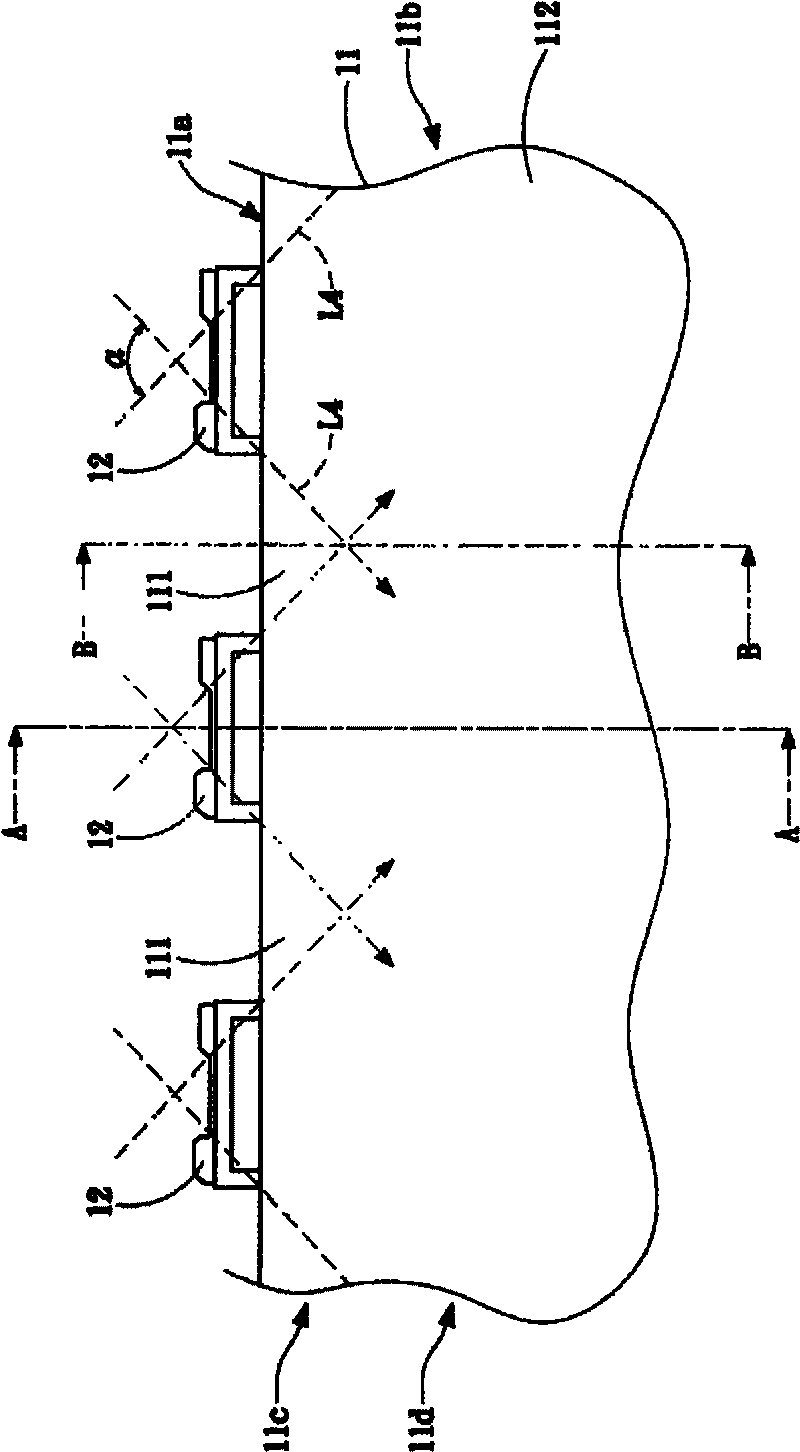

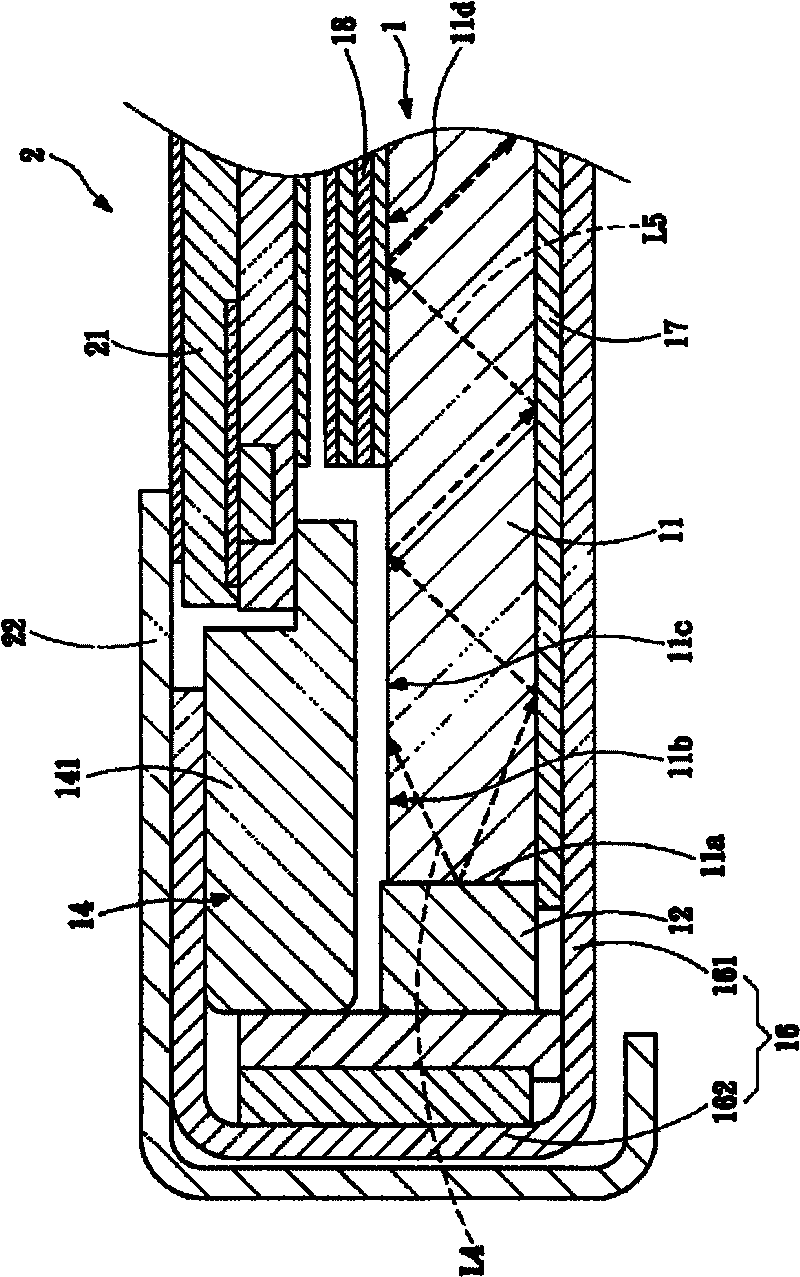

[0038] figure 2 and Figure 3A , Figure 3B and Figure 4A A first embodiment of the present invention is shown. The backlight module 1 includes: a light guide plate 11 , a plurality of light emitting elements 12 , and a positioning element 14 . Figure 3A for figure 2 The A-A section diagram, Figure 3B for figure 2 The B-B section diagram, Figure 4A Then it is a schematic diagram of the optical performance of this embodiment. Wherein, for the convenience of description and performance of the technical features of the present application, figure 2 Only the light guide plate 11 and the light emitting element 12 are kept, while other elements are omitted.

[0039] The light guide plate 11 is roughly in the shape of a parallelogram, including a light-incident surface 11 a and an upper surface 11 b , wherein the upper surface 11 b intersects the light-incident surface 11 a.

[0040] A plurality of light-emitting elements 12, each light-emitting element 12 preferabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com