Dual-tubesheet heat interchanger

A technology of heat exchangers and double tube sheets, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of easy corrosion and leakage of welding, to ensure welding quality, eliminate safety hazards, improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

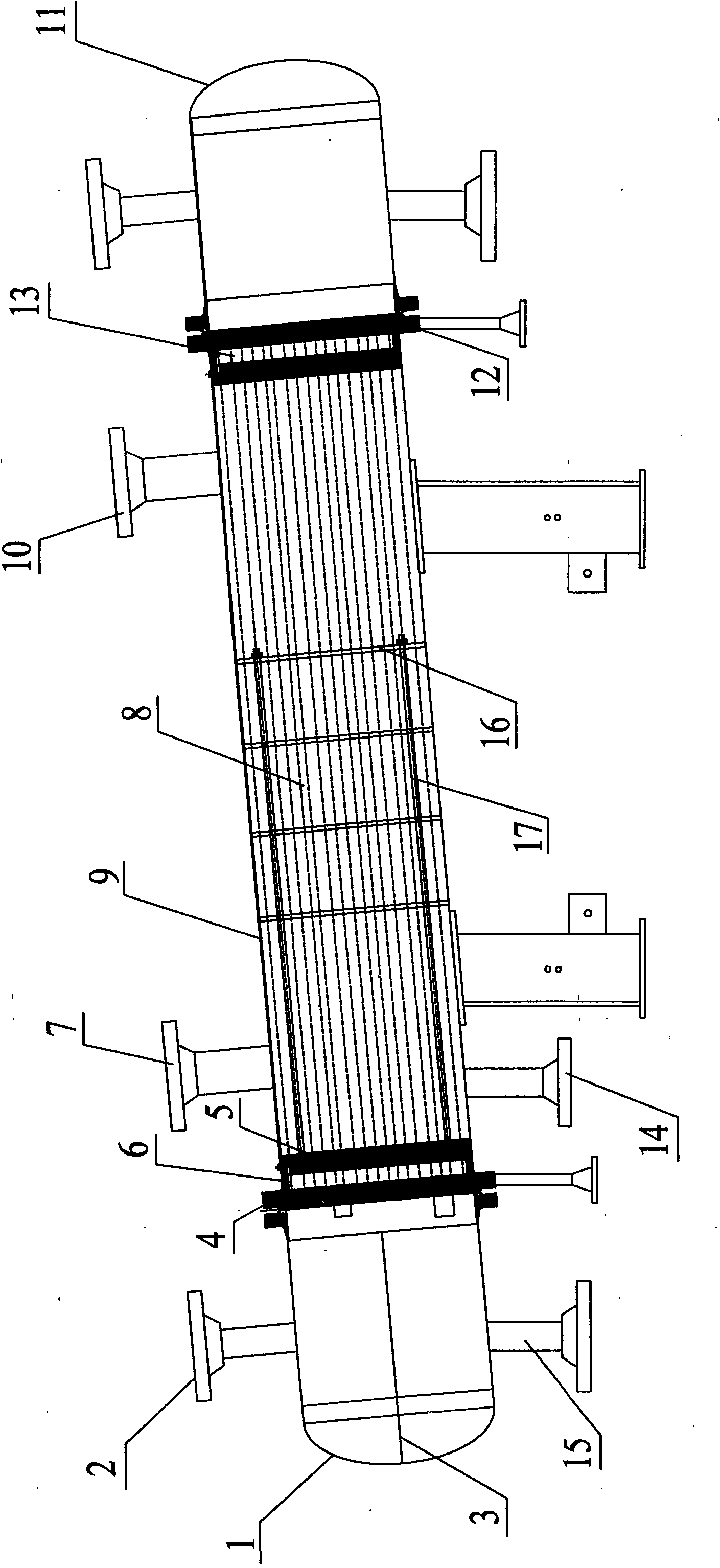

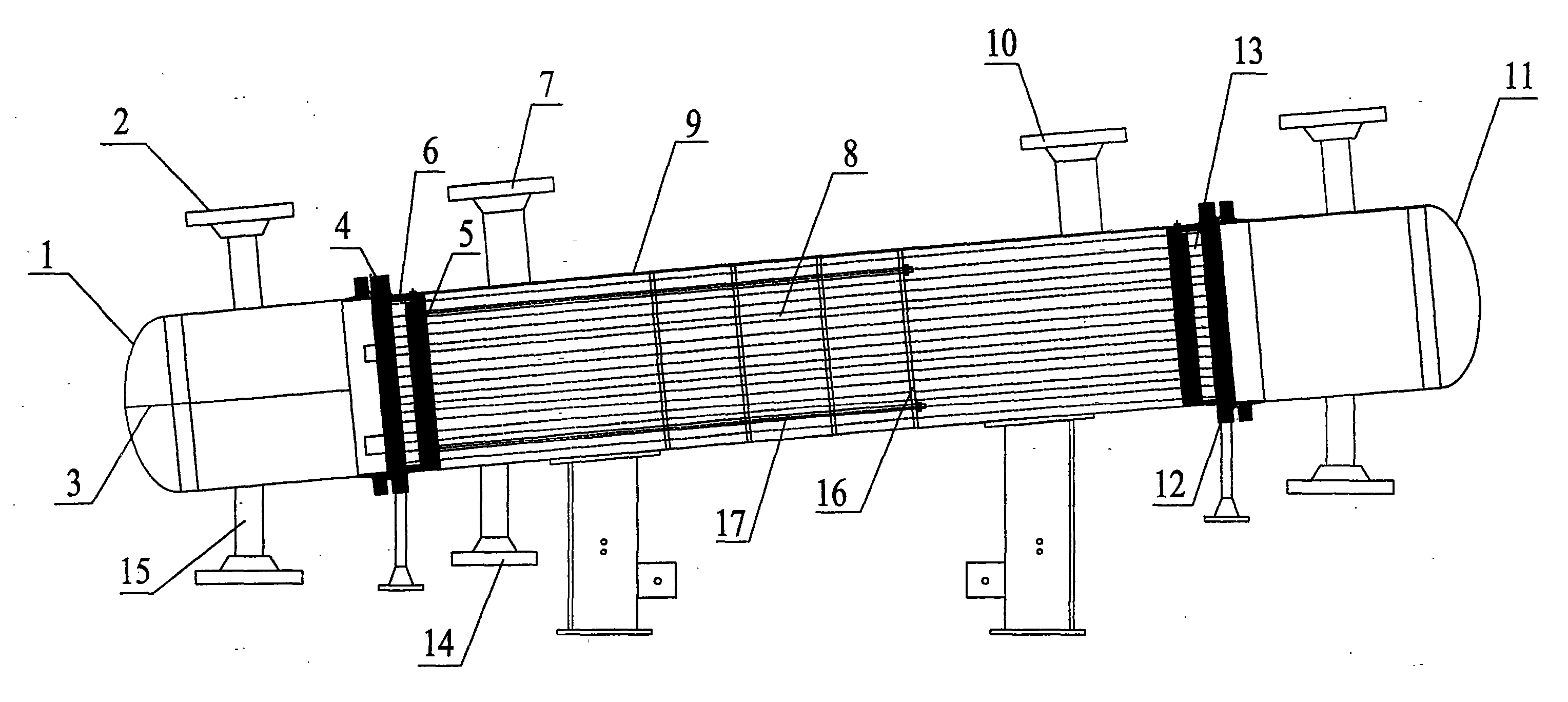

[0025] In order to better understand the shape, structure and characteristics of the present invention, the following examples are listed and described in detail with reference to the accompanying drawings.

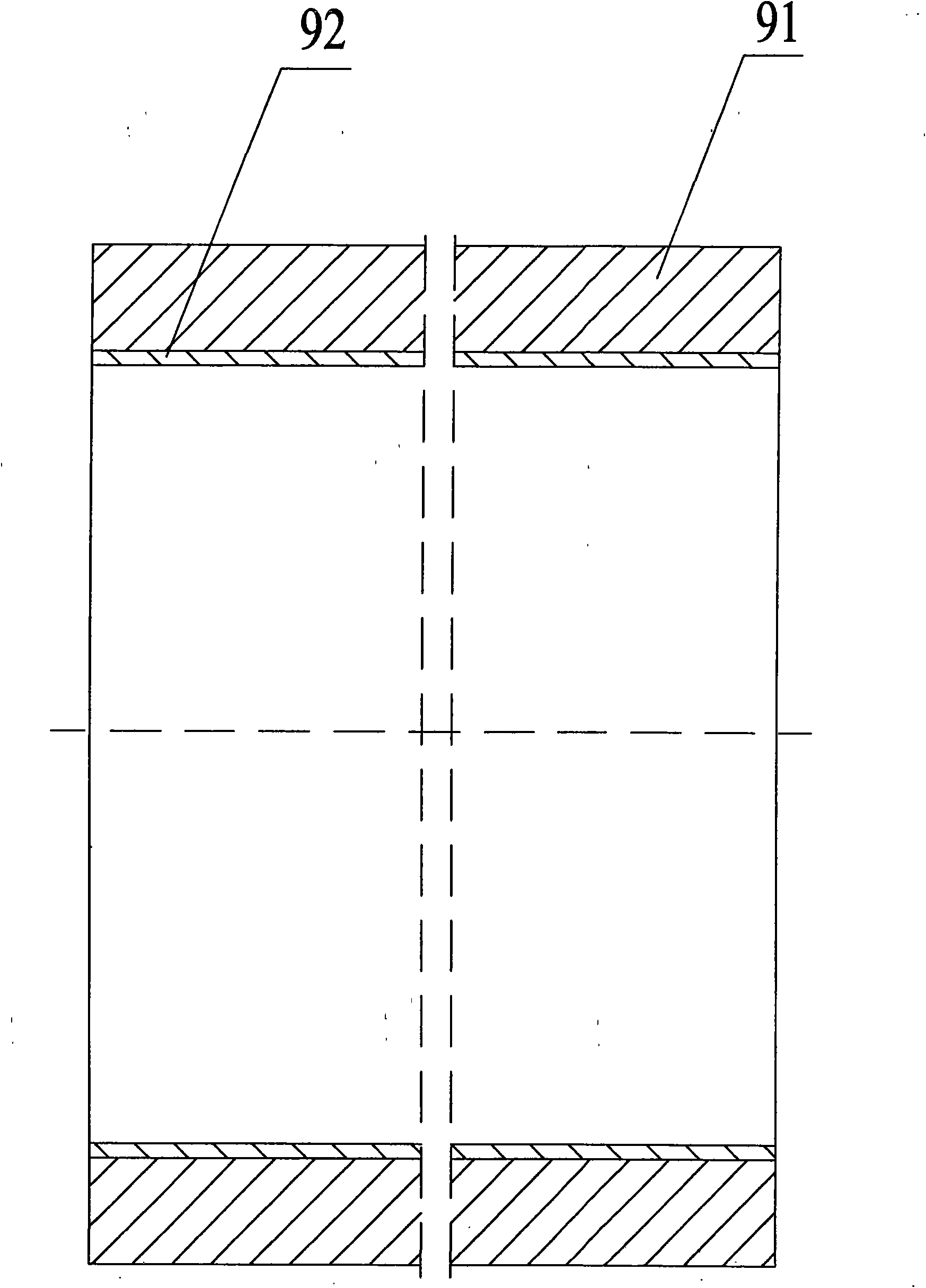

[0026] The double-tube-sheet heat exchanger of the present invention includes a cylinder body 9, and the two sides of the cylinder body 9 are respectively assembled with the left side tube box 1 and the right side tube box 11 through the tube box flanges. The material of cylinder 9 is a composite material formed by combining stainless steel plate 92 and low-alloy steel plate 91 by explosive compounding, and then the composite material is rolled into a cylinder by a plate rolling machine and welded to form cylinder 9 . specific structure, such as figure 1 As shown, the outer layer of the cylinder body 9 is a low-alloy steel plate 91 with a thickness of 40 mm to 60 mm, so as to meet the sufficient strength requirement of the cylinder body 9 . The inner layer of the cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com