Non-contact differential type speed encoder

A speed encoder, non-contact technology, applied in the field of speed encoder, can solve the problem of life reduction and other problems, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

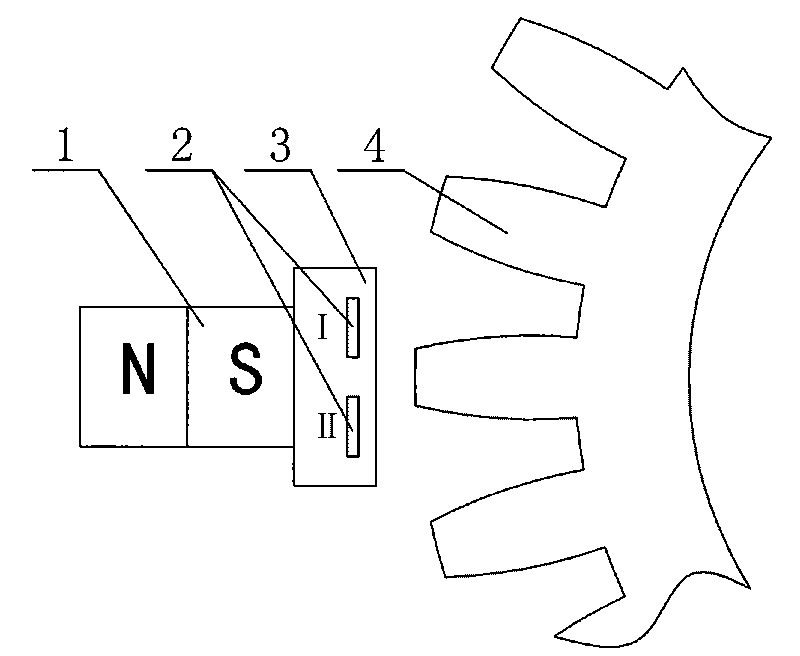

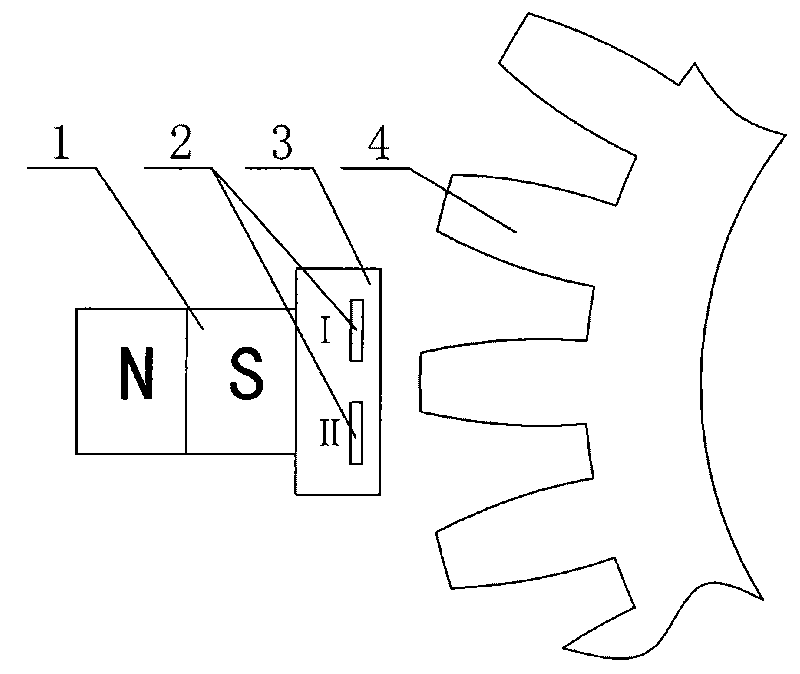

[0019] Such as figure 1 As shown, the non-contact differential speed encoder of the present invention is located on the outer side of the gear teeth of the speed measuring gear 4, and includes a magnetic element 1 and a Hall element 3, and the Hall element 3 is installed on / in the housing 2. The Hall elements 3 are symmetrically arranged, the housing 2 is made of plastic or other insulating materials, and two Hall elements 3 are arranged symmetrically.

[0020] The magnetic element 1 is located outside the Hall element 3 , the magnetic element 1 is a permanent magnet, and the magnetic field direction of the permanent magnet is perpendicular to the Hall element 3 .

[0021] The Hall element 3 outputs a high level when encountering a strong magnetic field, and outputs a low level when a weak magnetic field is encountered.

[0022] The back of the Hall element 3 uses a permanent magnet to generate a magnetic field. When the gap between the gears is aligned with the Hall element ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com