Multi-gear fault-tolerance permanent magnetism magnetic flux switching electric machine and fault-tolerance method thereof

A magnetic flux switching motor and permanent magnet technology, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of low power density and efficiency of the motor, and reduce the residual magnetism of the permanent magnet.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

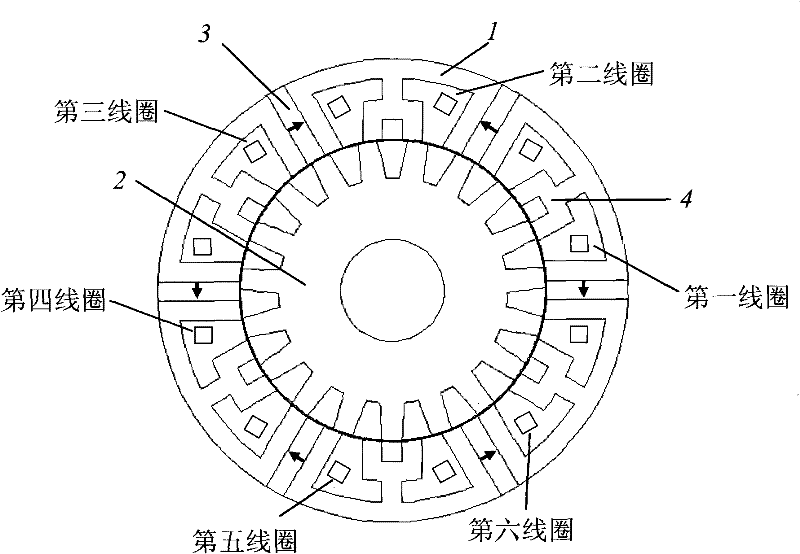

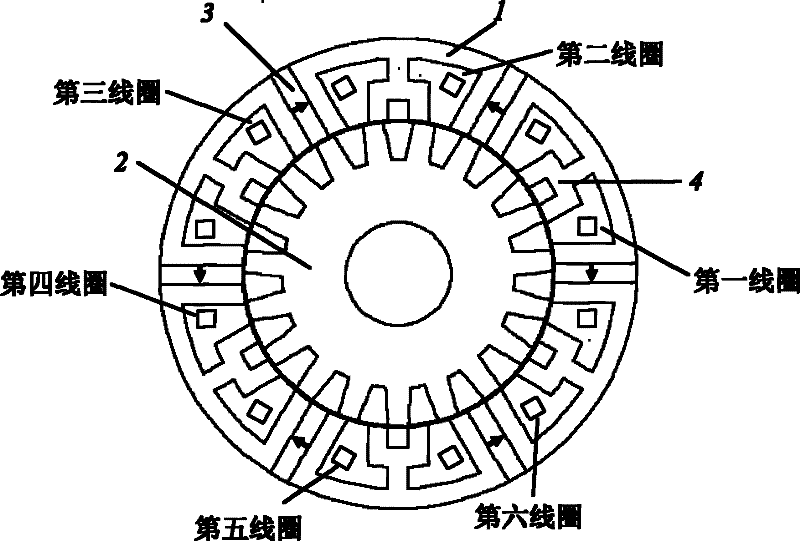

[0022] like figure 1 As shown, the multi-tooth fault-tolerant permanent magnet flux switching motor includes a salient pole stator, an armature winding, and a salient pole rotor 2, and is characterized in that:

[0023] The salient pole of the stator is an E-shaped stator iron block 1, and the gap between each two E-shaped stator iron blocks is embedded in a bar-shaped permanent magnet 3 in turn, and the stator winding is wound on the two E-shaped arms connected by the above-mentioned bar-shaped permanent magnet, that is, the first coil to the sixth coil.

[0024] The magnetically separated teeth of the E-type stator iron block are "Y"-shaped structures, so that the number of stator teeth is four times the number of bar-shaped permanent magnets. The "Y" structure magnetic separation tooth greatly increases the magnetic permeability of the separation tooth circuit and reduces the mutual inductance of the adjacent coils of the stator winding.

[0025] The rotor adopts a multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com