Determination method of production technology parameter of external cooling water in middle-plate hot leveller

A technology of production process and determination method, which is applied in the field of determination of process parameters of external cooling water of medium-plate hot straightening machine, can solve problems such as inability to accurately determine process parameters, achieve convenient operation, improve service performance and life, and improve quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

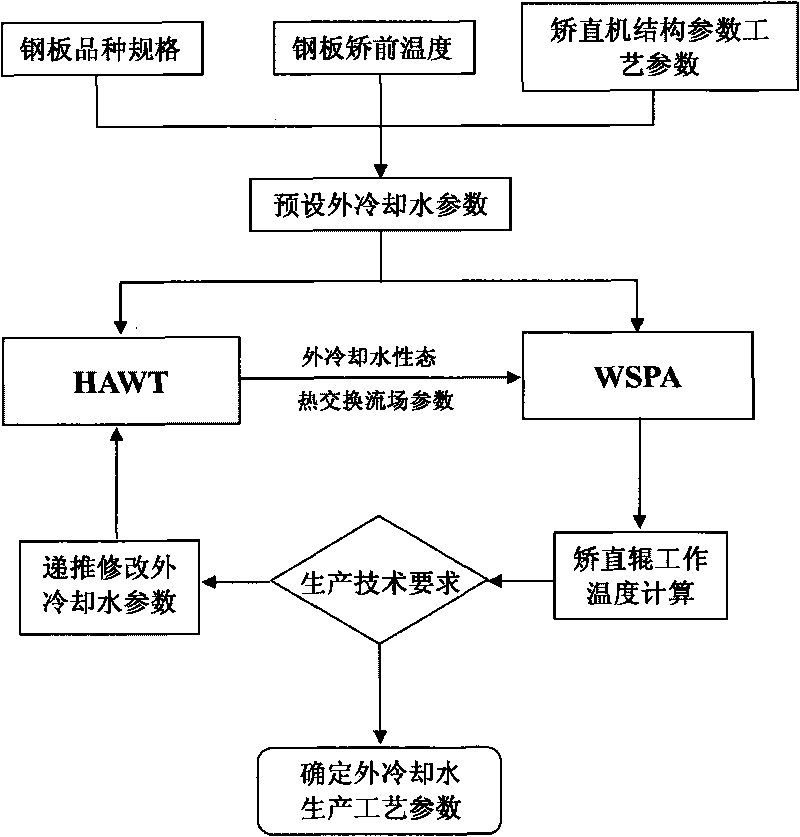

[0016] A method for determining the production process parameters of the external cooling water of a medium-plate thermal straightening machine, characterized in that the method determines the production process parameters of the external cooling water according to the heat-fluid-solid coupling dynamics, see figure 1 , including the following steps:

[0017] (1) Establish the heat-air-water mixed exchange model HAWT between the external cooling water and the steel plate, straightening roller and external field space; this model includes the vaporization process of the external cooling water on the straightening roller and the steel plate, the mixing of water liquid and steam Flow process, steel plate heat radiation heating process of water and steam.

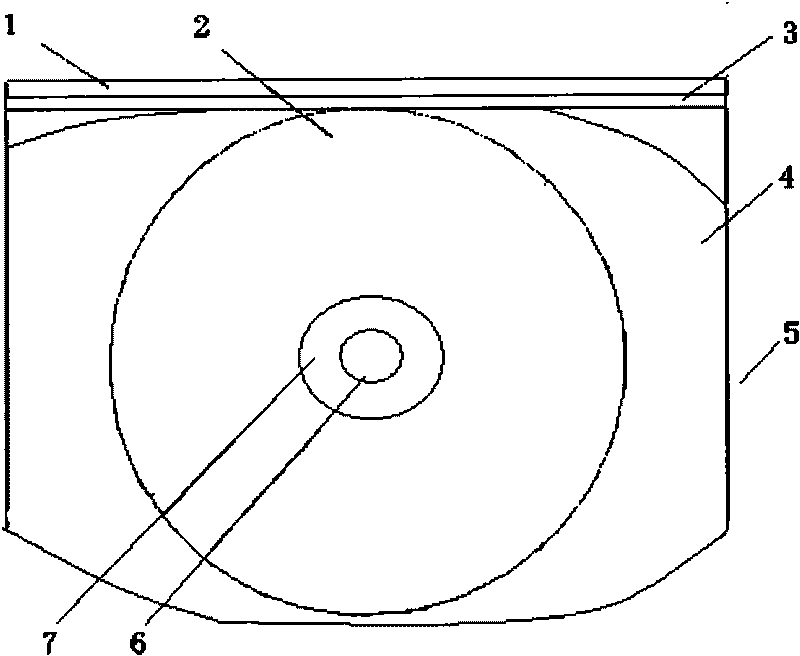

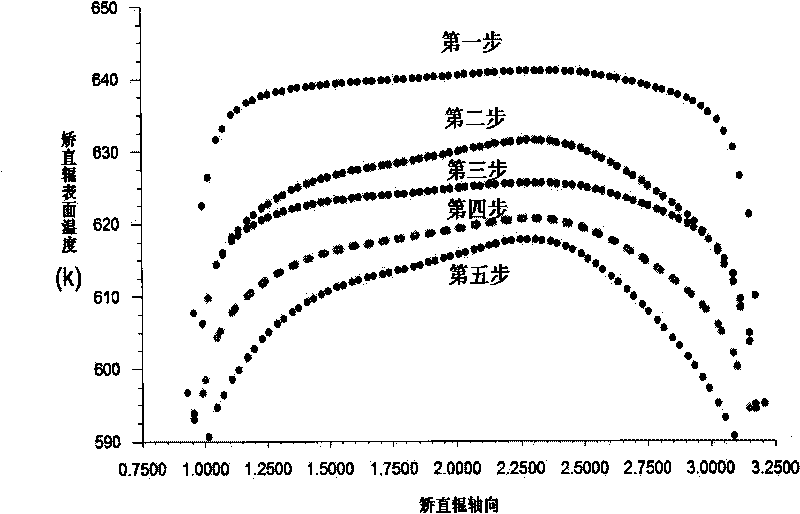

[0018] (2) Establish the heat-fluid-solid structure model WSPA of the external cooling water, straightening rollers, steel plates and the external air field; Calculation of solid heat transfer for straightening rollers, calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com