Method for dipping vermilion glaze on ceramic winebottle

A ceramic wine bottle and vermilion glaze technology, which is applied in the field of ceramic wine bottle dipping glaze, can solve the problems of narrow application range, etc., and achieve the effect of increased product price, unique and novel formula, and deep color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

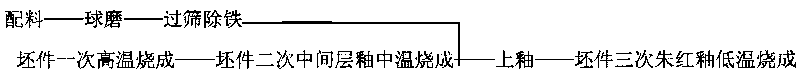

Method used

Image

Examples

Embodiment 1

[0012] 1) Use red lead, borax, and quartz as raw materials to prepare frit, and its weight ratio is: red lead 70%, borax 20%, quartz 10%, and then press frit 82.3%, cadmium selenium red pigment 15.7%, Suzhou Soil 2% ingredients, put into a ball mill and ball mill for 24 hours to obtain a glaze, sieve with a 320 mesh sieve, add water to dilute to 61 Baume and set aside.

[0013] 2. The blank is fired once at 1160°C, the upper middle layer glaze is fired at 1135°C, and finally the vermilion glaze is fired. The firing temperature is 750-780°C.

Embodiment 2

[0015] 1) Use red lead, borax, and quartz as raw materials to prepare frit, and its weight ratio is: red lead 68%, borax 25%, quartz 12%, and then press frit 80%, cadmium selenium red pigment 14%, Suzhou Soil 6% batching, put into ball mill and ball mill for 24 hours to obtain glaze, sieve with 320 mesh sieve, add water to dilute to 61 Baume and set aside.

[0016] 2. The blank is fired once at 1160°C, the upper middle layer glaze is fired at 1135°C, and finally the vermilion glaze is fired. The firing temperature is 750-780°C.

Embodiment 3

[0018] 1) Use red lead, borax, and quartz as raw materials to prepare frit, and its weight ratio is: red lead 72%, borax 20%, quartz 8%, and then press frit 84%, cadmium selenium red pigment 10%, Suzhou Soil 6% batching, put into ball mill and ball mill for 24 hours to obtain glaze, sieve with 320 mesh sieve, add water to dilute to 61 Baume and set aside.

[0019] 2. The blank is fired once at 1160°C, the upper middle layer glaze is fired at 1135°C, and finally the vermilion glaze is fired. The firing temperature is 750-780°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com