Device for measuring damping ratio of damper

A technology of damper and damping rate, which is applied in the direction of measuring devices, testing of machines/structural components, instruments, etc., to achieve the effects of high test accuracy, small temperature drift, and improved reliability and development level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

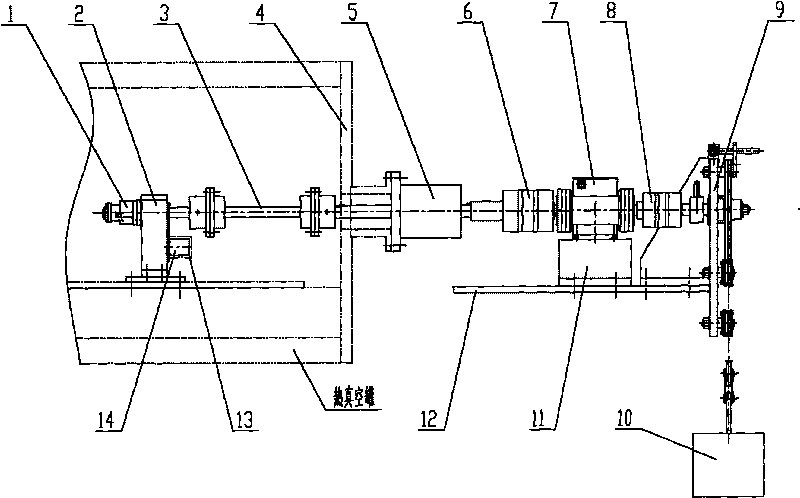

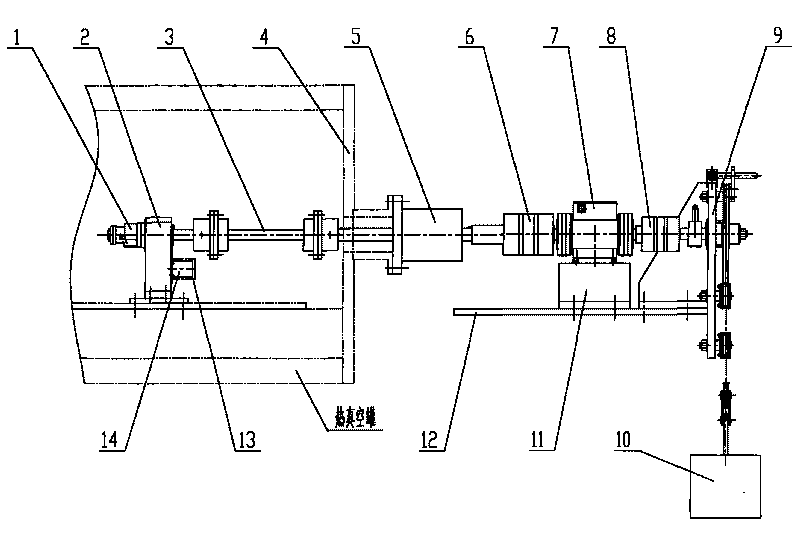

[0015] A device for testing damper damping rate of the present invention, such as figure 1 As shown, it includes the tested damper 1, the test bracket 2, the spherical cage synchronous universal coupling 3, the rear flange cover 4, the magnetic fluid sealing device 5, the coupling A6, the torque sensor 7, the coupling B8, Loading device 9, sensor support 11, base 12, temperature control device 13 and angle encoder 14, loading device 9 contains loading weight 10; loading device 9 is fixedly connected with base 12, and sensor support 11 is fixedly connected with base 12 , the torque sensor 7 is installed on the sensor support 11, the torque sensor 7 is a biaxial extension, one end is connected to the loading device 9 through the coupling B8, and the other end is connected to one end of the magnetic fluid sealing device 5 through the coupling A6, the magnetic fluid The flange of the sealing device 5 is fixedly connected with the rear flange cover 4 of the hot vacuum tank, and ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com