Friction force controllable bracket

A friction and controllable technology, applied in brackets, medical science, dentistry, etc., can solve problems such as loss of bracket shaft inclination and torque angle, inconvenient replacement of chain elastic rings, and difficulty in controlling the position of teeth. To achieve the effect of reducing friction, accelerating movement, and reducing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

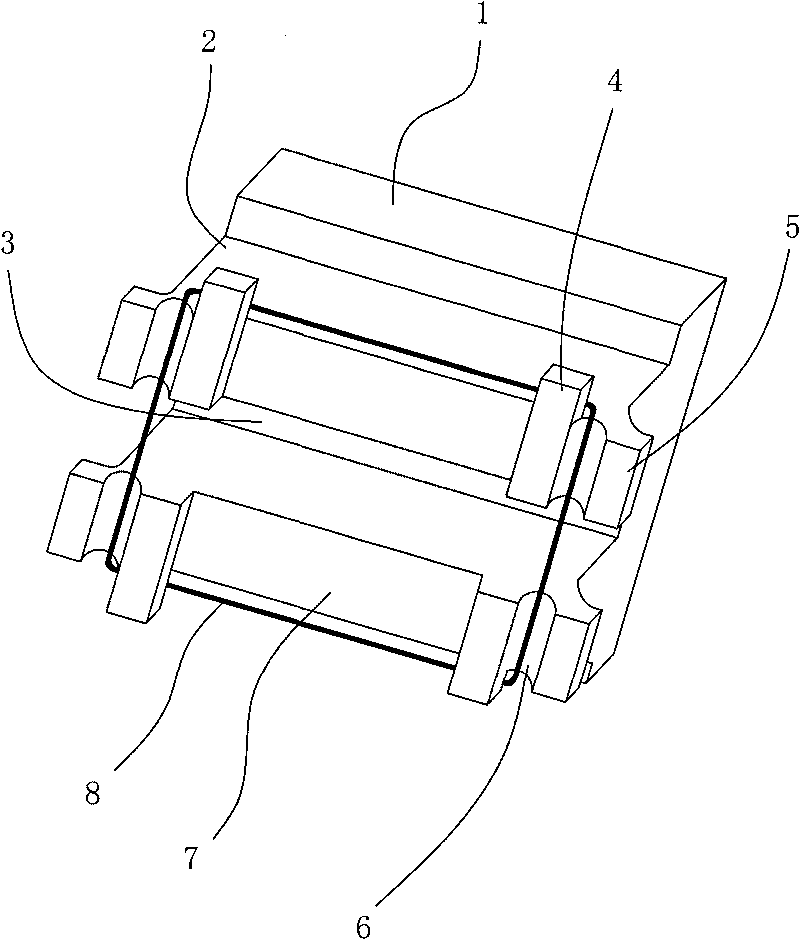

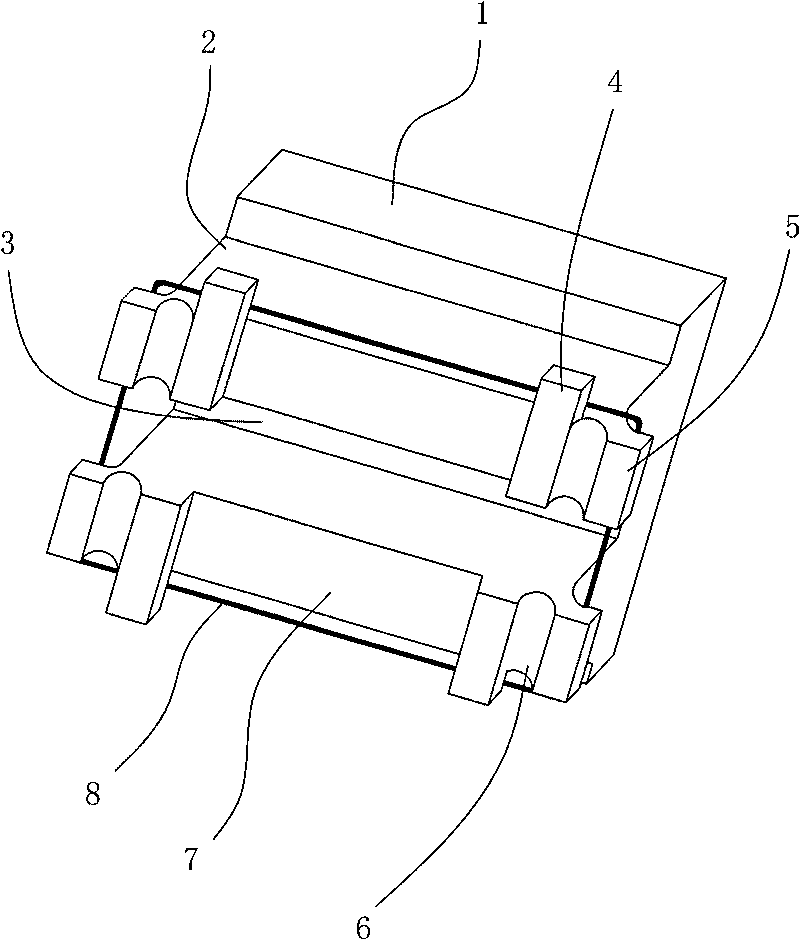

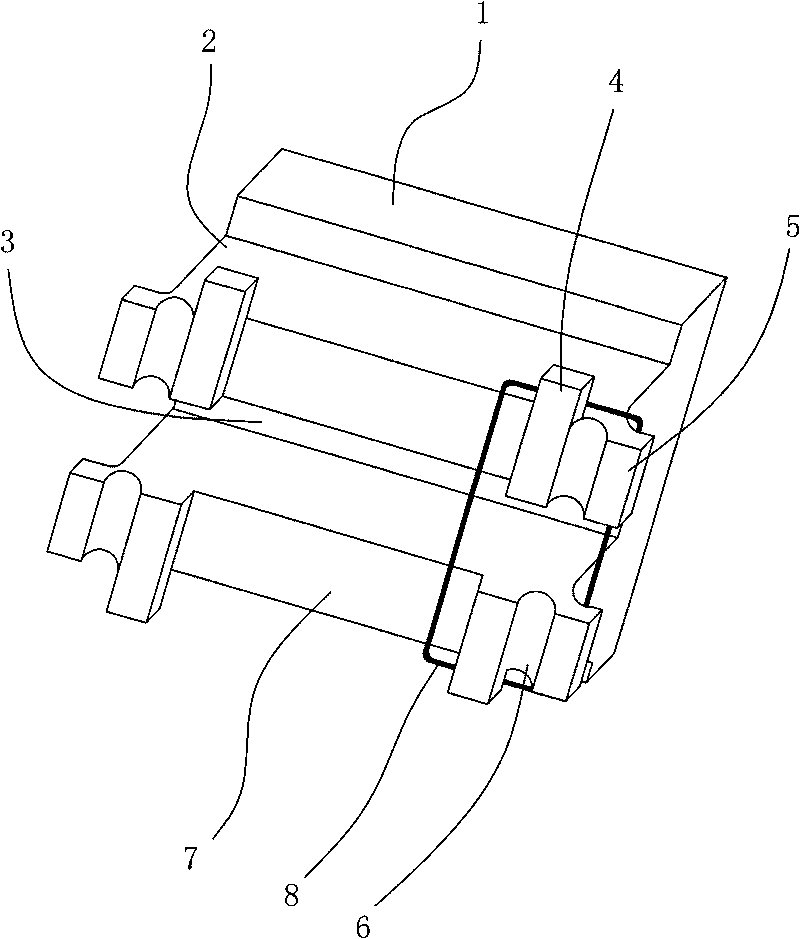

[0020] figure 1 It is a schematic diagram of the structure of the present invention in the first state of use. As shown in the figure, a friction controllable bracket includes a base plate 1 and two bracket bodies 2 fixedly arranged on the base plate 1 in parallel and opposite; An archwire groove 3 at a certain angle to the bottom plate 1 is formed between the bracket bodies 2; both ends of the bracket body 2 are respectively provided with protruding directions opposite to the archwire groove 3 Gingival wings 4 and lateral wings 5 protruding to the side; two The gingival wings 4 are located on the inner side of the two side wings 5 and extend out of the bracket body 2 in a direction parallel to the bottom plate 1; the side wings 5 extend out of the bracket body 2 in a direction parallel to the bottom plate 1; A ligature groove 6 is formed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com