Screw rod type concrete mixer tank

A concrete and screw-type technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of increasing labor costs, manual cleaning, and reducing the use efficiency of tanks, so as to reduce the number of cleaning tanks, The effect of reducing the driving force of stirring and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

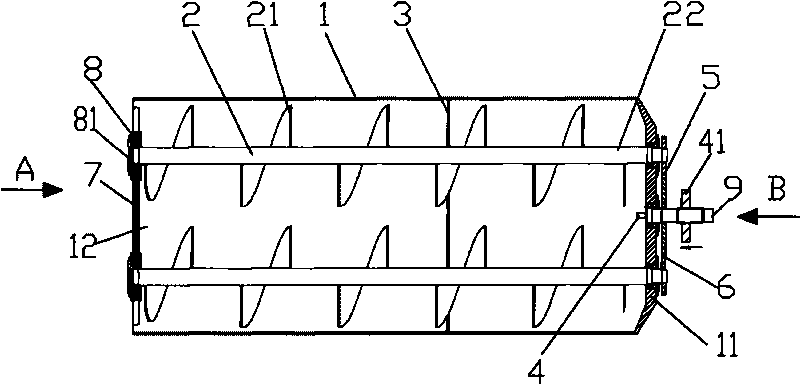

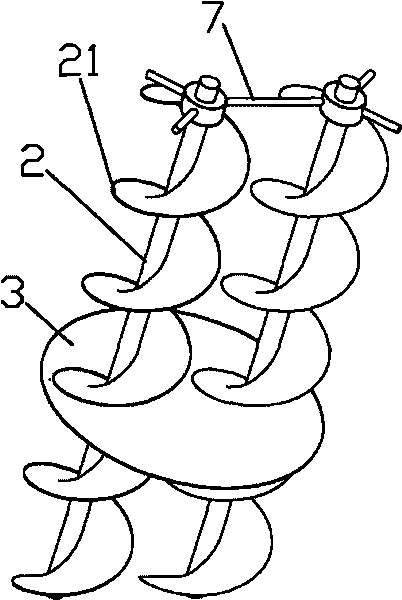

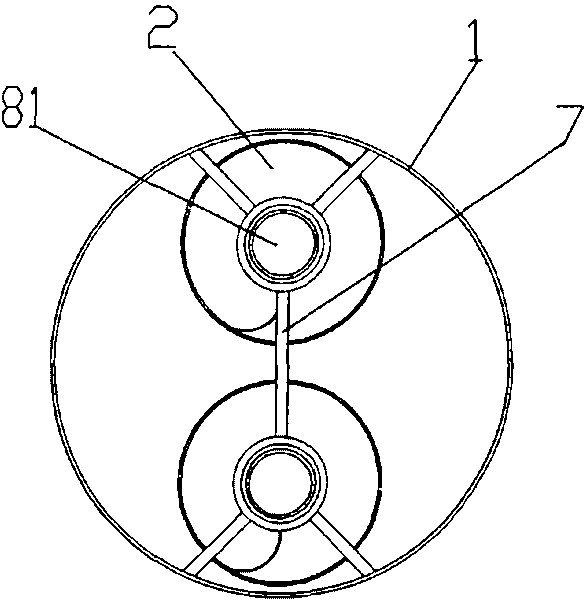

[0020] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 It is a three-dimensional schematic diagram of the cooperation between the screw rod and the round nut of the present invention, image 3 for figure 1 View along direction A, Figure 4 for figure 1 View along direction B, Figure 5 It is a schematic diagram of the ejector rod of the present invention, as shown in the figure: the screw type concrete mixer truck tank of the present embodiment includes a tank body 1, the upper end of the tank body 1 is provided with a feed port 12, and the lower end is a tank bottom 11, and the inside of the tank body 1 At least one screw 2 is arranged longitudinally, the screw thread of the screw 2 is formed by a helically expanded blade 21, and a round nut 3 is arranged in cooperation with the screw 2, and the round nut 3 and the inner surface of the tank body 1 can slide axially. Single-degree-of-freedom cooperation; screw rod 2 lower end single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com