Compound all-loading coach body

A full-load, composite technology, applied in the field of passenger car bodies, can solve the problem of weak local bearing capacity, and achieve the effect of reducing the self-weight of the whole vehicle, improving the anti-overload capacity and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical content of the present invention will be described in detail below in conjunction with the specific implementation structure of each accompanying drawing.

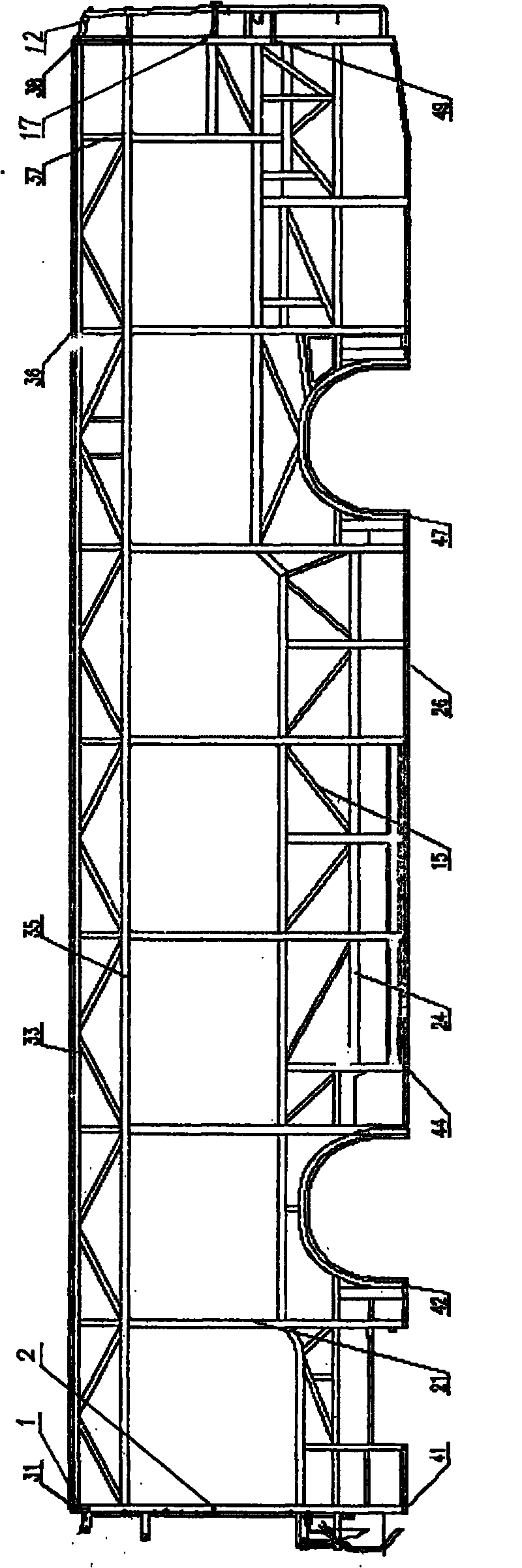

[0023] The composite full load passenger car body includes a front wall assembly, two side wall assemblies, a rear wall assembly, a top cover assembly and an underframe assembly.

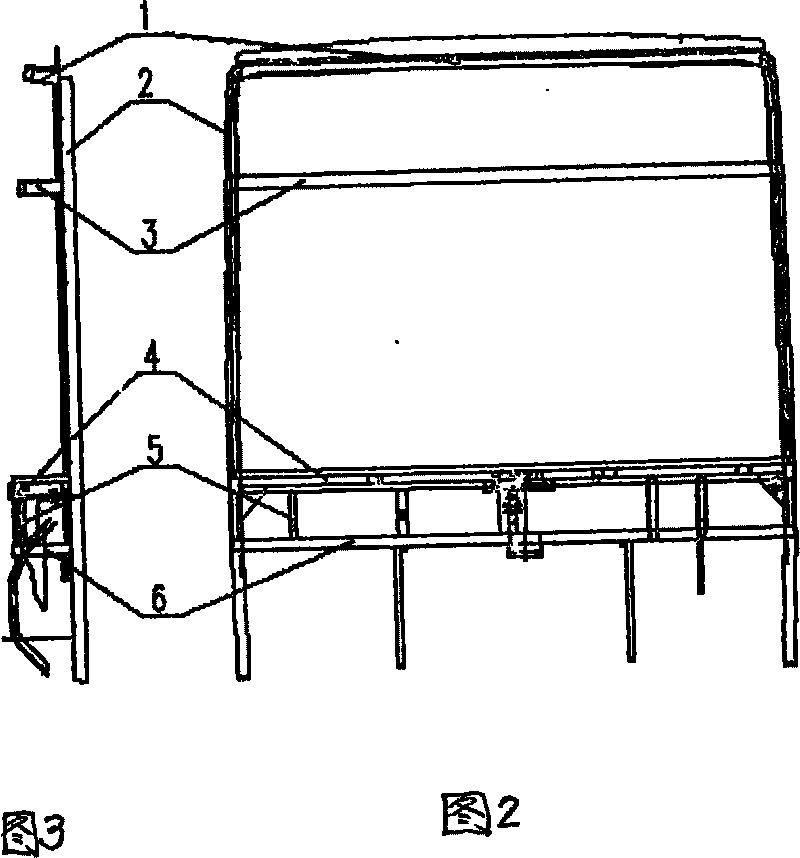

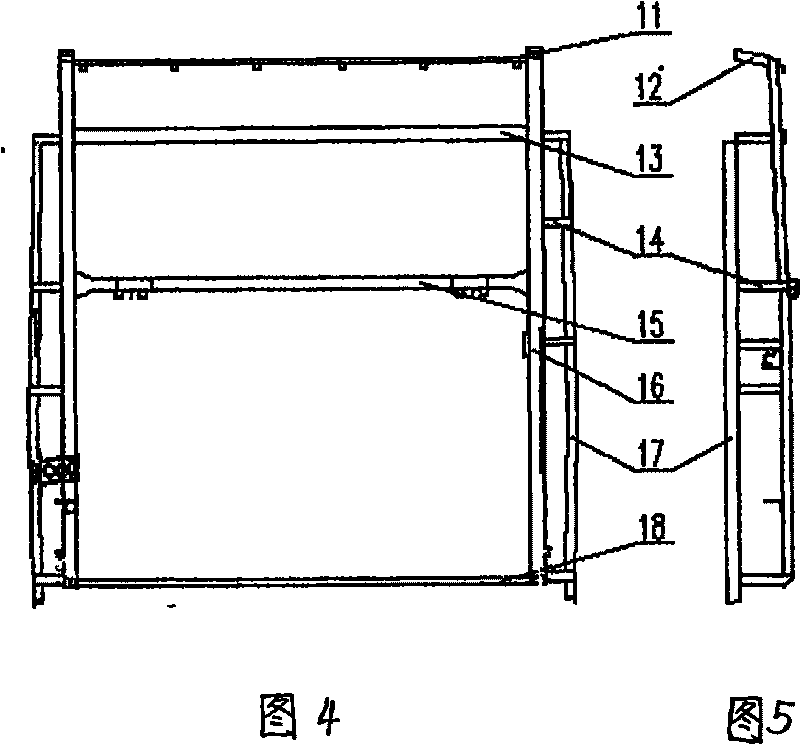

[0024] Such as figure 2 and image 3 As shown, the composition of the front wall assembly includes a windshield upper beam assembly 1, a front windshield first lower beam assembly 4, and a front windshield second lower beam assembly 6. The windshield connecting beam 3, these beam members are connected and supported by the left and right front wall columns 2 on both sides to form a front wall frame structure, and the left and right front wall columns 2 are through-type integral columns to improve the bearing capacity of the front wall assembly The first lower beam assembly 4 and the second lower beam assembly 6 of the wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com