Vertical shaft wind-driven generation system structure and control method thereof

A technology of a wind power generation system and a control method, which is applied to the control of wind turbines, wind energy power generation, wind turbines, etc., can solve the problems of poor self-starting capability of a lift-type system, low output efficiency of a drag-type system, and inability of the system to self-start, etc. Achieve the effect of reducing generator speed and output efficiency, improving self-starting capability and reducing output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

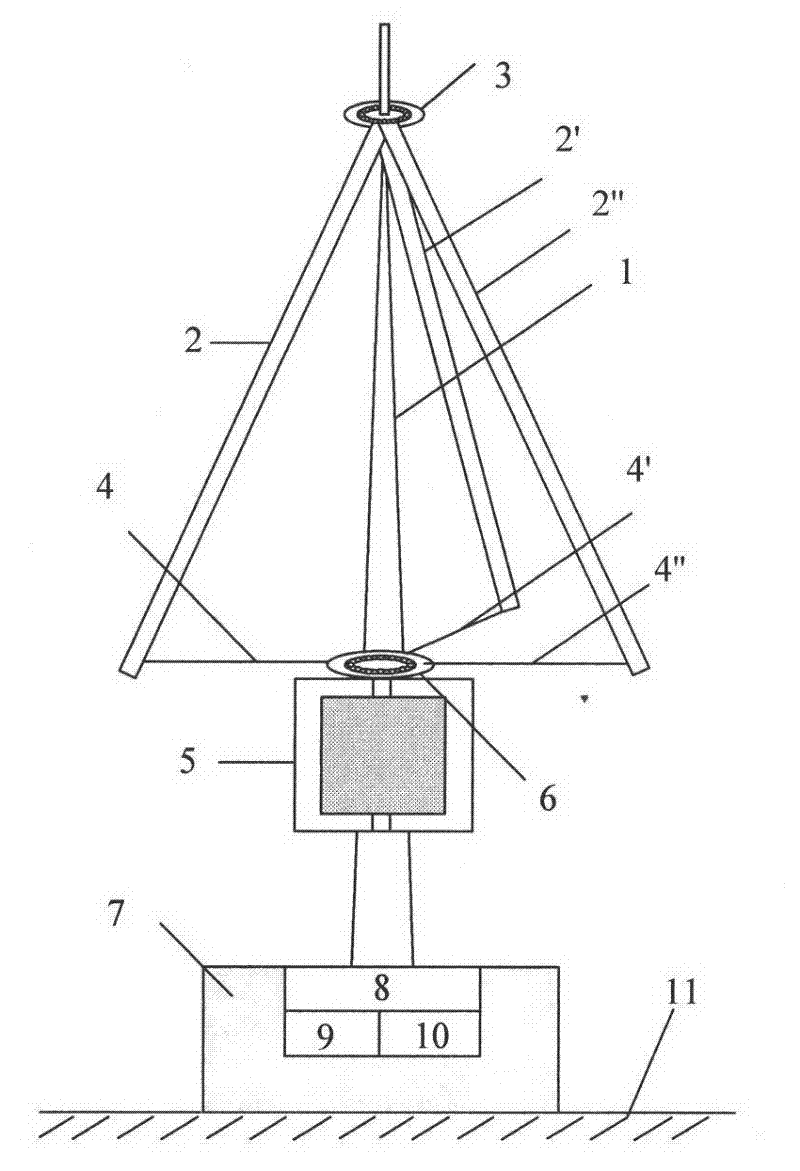

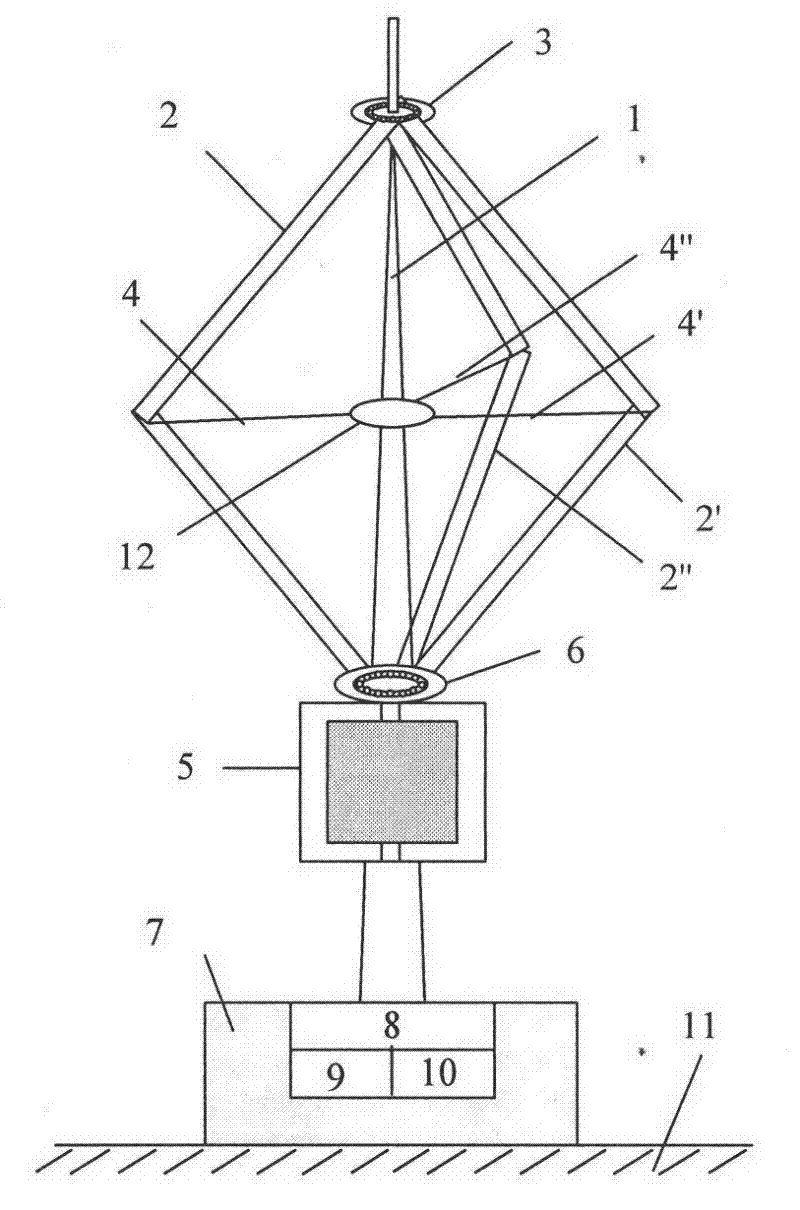

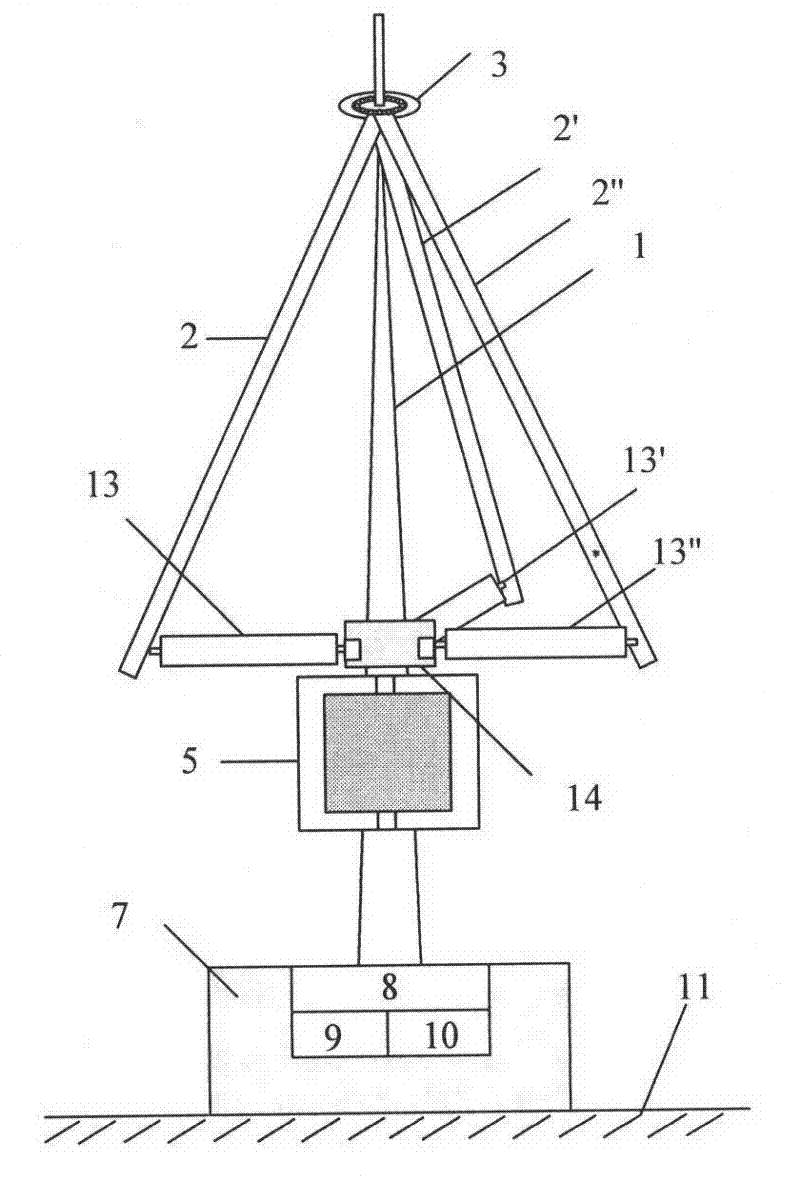

[0025] Taking the selected Δlift wind power generation system as an example, the rated power of the generator is 500W, the rated voltage is 50V, the rated current is 10A, the blade length of the fixed-pitch fan is 1.5m, and the blade length of the variable-pitch fan is 1.5m. The length is 0.8m, the width is 0.5m, the set cut-in wind speed is 3m / s, the cut-out wind speed is 20m / s, and the rated wind speed is 15m / s.

[0026]Taking the actual wind speed of 5m / s as an example, the steps of the control method are as follows: ①Set the rated power of the generator to 500W, the rated voltage to 50V, and the rated current to 10A. If the rated wind speed is 20m / s and the rated wind speed is 15m / s, perform step ②; ②The blades of the variable-pitch fan are perpendicular to the ground and close the braking device, and perform step ③; If there is technology, the output voltage value of the generator is 40V, the output current is 0.625A, and the output power is 25W, and the step ④ is execute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com