Excircle cavity opening type dynamic-static pressure main shaft unit

A dynamic and static pressure, main shaft technology, applied in the directions of shafts, bearings, shafts and bearings, can solve problems such as difficulty in ensuring shape tolerance and position tolerance, difficulty in processing dynamic and static pressure bearings, and difficulty in ensuring position, so as to improve labor productivity and ease of use. The effect of processing and reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to clearly illustrate the technical characteristics of this solution, the following implementation examples illustrate this solution.

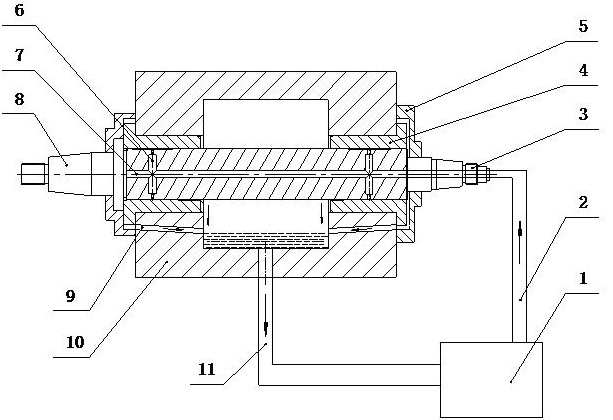

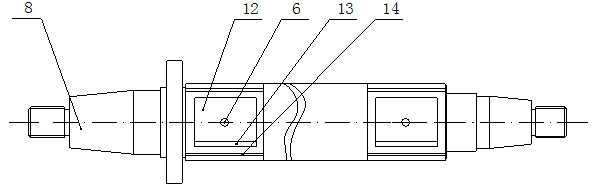

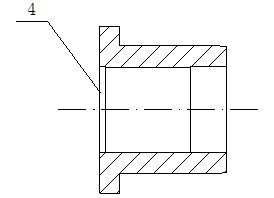

[0017] See figure 1 , figure 2 with image 3 , The present invention is an external open cavity type dynamic and static pressure main shaft unit, including a dynamic and static pressure main shaft 8, a dynamic and static pressure bearing 4 and an oil supply system, wherein the hydrostatic and dynamic pressure main shaft 8 is provided with several circumferentially evenly distributed oil cavities on the outer cylindrical surface of the journal; The oil cavity is composed of a deep cavity 13 and a shallow cavity 12. The radial cross section formed by the deep cavity 13 and the shallow cavity 12 is stepped; the dynamic and static pressure spindle 8 is provided with an axial oil inlet 7 and the journal of the dynamic and static pressure spindle 8 A radial oil outlet hole 6 communicating with the axial oil inlet hole 7 is provided, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com