Floating impeller serial hydraulic turbine

A water turbine and floating technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of large diameter of a single set of blades, inconvenient maintenance and management, and low power of the device, so as to improve safety, facilitate maintenance and Effects of improved management and utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

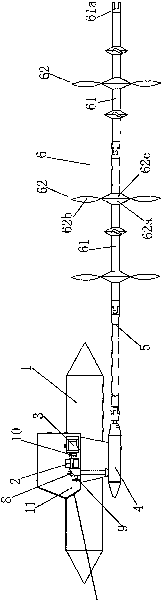

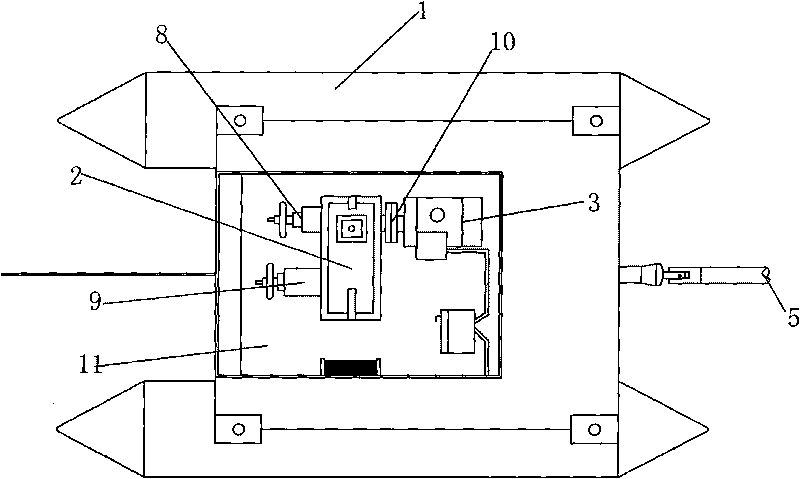

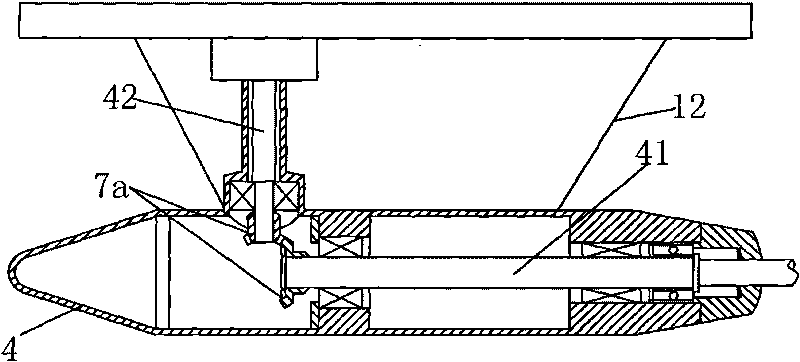

[0027] Figure 1 to Figure 6 Constitute the specific embodiment 1 of the present invention.

[0028] refer to figure 1 , figure 2 and image 3 , the present embodiment includes a floating body 1, a transmission gearbox 2 arranged on the floating body 1, a generator 3, a bevel gearbox 4 arranged at the bottom of the floating body, a transmission shaft 5 and an impeller group 6; the impeller group 6 includes two The serial shafts 61 connected to each other are provided with three impellers 63; one end of the transmission shaft 5 is connected to the serial shaft 61 at one end of the impeller group 6 through a universal coupling, and the other end is connected to the bevel gear box 4 The input shaft 41 of the bevel gear box 4 is connected to the input shaft 41 of the bevel gear box 4 with the vertical output shaft 42 through the bevel gear 7; The high speed shaft 22 is connected with the input shaft of the motor 3 . The tandem shaft 61 is a hollow tube that is connected with...

specific Embodiment 2

[0034] The feature of this embodiment is that the brake 8 is an electro-hydraulic block brake. Others are the same as in Example 1.

specific Embodiment 3

[0035] The feature of this embodiment is: the anti-rotation device 9 is an electrically controlled anti-rotation device. Others are identical with specific embodiment 1 or 2.

[0036] Other examples:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com