Manufacturing method of servo motor solenoid coil

A technology for electromagnetic coils and manufacturing methods, applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of unsafe electromagnetic coils, reduce the service life of electromagnetic coils, and burnout of electromagnetic coils, and achieve low cost and long life. The effect of long service life and low abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

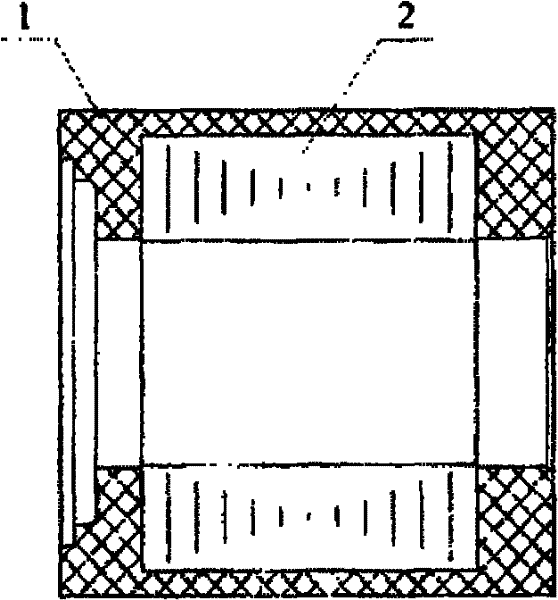

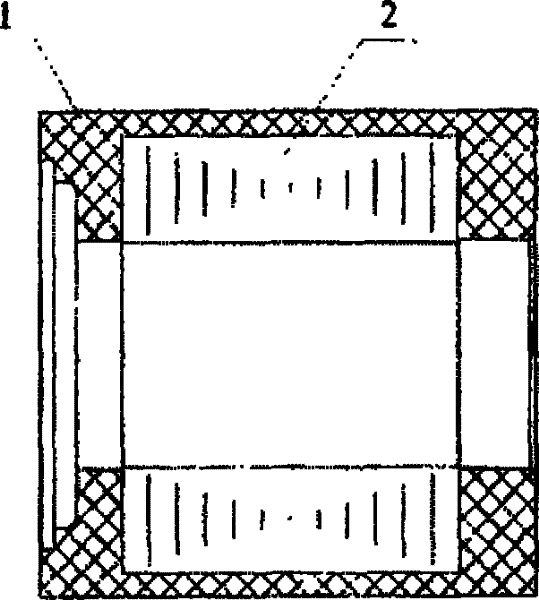

Image

Examples

Embodiment 1

[0036] Embodiment 1: A manufacturing method of a servo motor electromagnetic coil, including pre-pressing preparation and press forming, and the pre-pressing preparation includes the following steps in sequence:

[0037] (1) Quality inspection of BMC unsaturated polyester plastic packaging materials, unqualified materials must not be used;

[0038] (2) Clean the mold, especially the pressing cavity, use compressed air to flush the mold cavity, use bamboo chips to clean the corners, do not use metal tools, so as not to scratch the surface of the mold cavity, and ensure that there is no residue in the mold;

[0039] (3) The press is tested. If the mold is closed too slowly, it is easy to have curing spots or defects on the surface of the product, so the closing speed of the press should be fast. When the fast closing of the press is close to the end, the mold closing speed should be adjusted immediately. Appropriately slowing down the closing process, on the one hand, is conduci...

Embodiment 2

[0064] Embodiment 2: A method of manufacturing a servo motor electromagnetic coil, including pre-pressing preparation and press forming, and the pre-pressing preparation includes the following steps in sequence:

[0065] (1) Quality inspection of BMC unsaturated polyester plastic packaging materials, unqualified materials must not be used;

[0066] (2) Clean the mold, especially the pressing cavity, use compressed air to flush the mold cavity, use bamboo chips to clean the corners, do not use metal tools, so as not to scratch the surface of the mold cavity, and ensure that there is no residue in the mold;

[0067] (3) The press is tested. If the mold is closed too slowly, it is easy to have curing spots or defects on the surface of the product, so the closing speed of the press should be fast. When the fast closing of the press is close to the end, the mold closing speed should be adjusted immediately. Appropriately slowing down the closing process, on the one hand, is conduci...

Embodiment 3

[0085] Embodiment 3: A method for manufacturing a servo motor electromagnetic coil, including pre-pressing preparation and press forming, and the pre-pressing preparation includes the following steps in sequence:

[0086] (1) Quality inspection of BMC unsaturated polyester plastic packaging materials, unqualified materials must not be used;

[0087] (2) Clean the mold, especially the pressing cavity, use compressed air to flush the mold cavity, use bamboo chips to clean the corners, do not use metal tools, so as not to scratch the surface of the mold cavity, and ensure that there is no residue in the mold;

[0088](3) The press is tested. If the mold is closed too slowly, it is easy to have curing spots or defects on the surface of the product, so the closing speed of the press should be fast. When the fast closing of the press is close to the end, the mold closing speed should be adjusted immediately. Appropriately slowing down the closing process, on the one hand, is conduci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com