Vacuum-conditioning and loosening feeding device

A technology of feeding device and vacuum resuscitation, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of large equipment area, long process flow in the tobacco sheet processing section, and process quality loss, etc. Moisture loss and temperature reduction, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

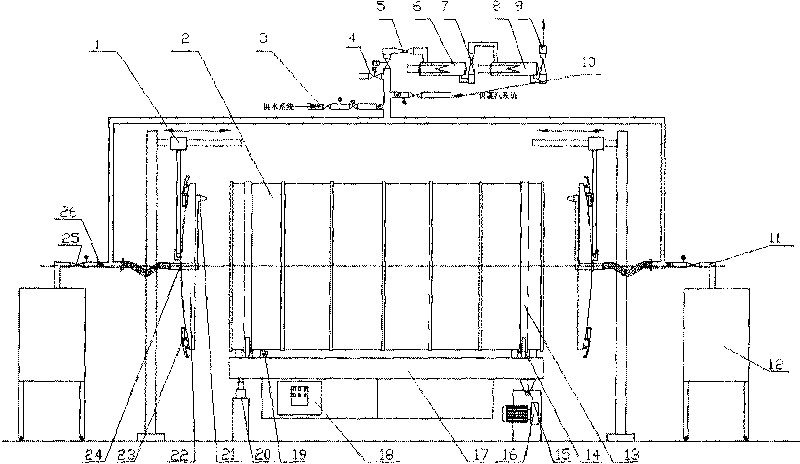

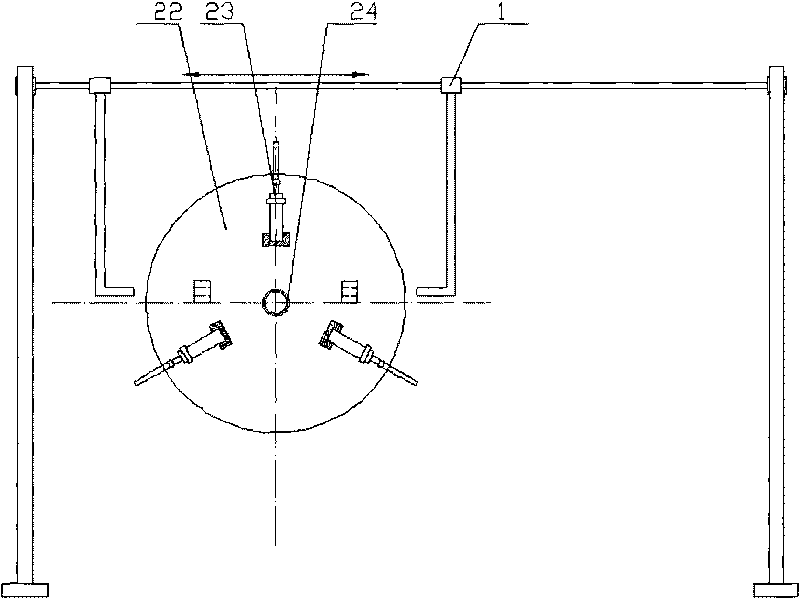

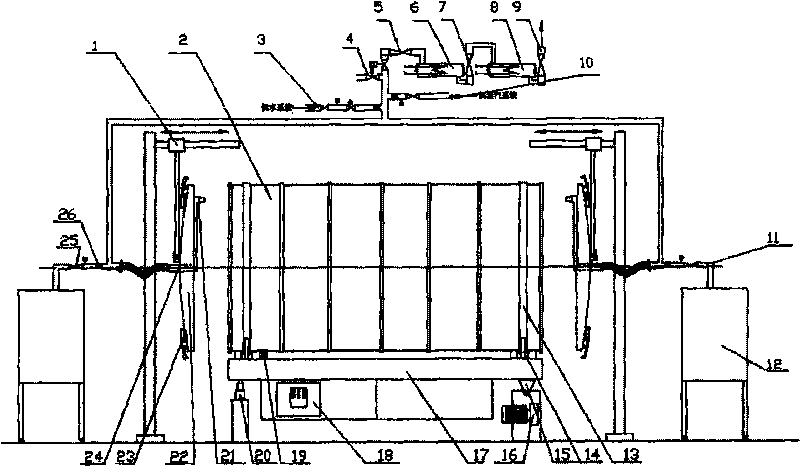

[0026] The present invention is further described below in conjunction with accompanying drawing:

[0027] Such as figure 1 , 2 Shown: the vacuum resurgence loose feeding device of the present invention comprises a drum, a drum support transmission system, a vacuum system, and a water and steam feeding system. The inner cavity of the drum is connected, and the operation of the drum, the vacuum system and the water, steam and feeding system are all controlled by the control system.

[0028] The rotating drum is composed of an independent cylinder body (2) and cylinder doors (22) at both ends of the cylinder body. The cylinder door can be sealed by three cylinder door locking cylinders (23) fixed on the cylinder door. It can also be separated from the cylinder by the reciprocating mechanism (1), and the cylinder door can be driven by the reciprocating mechanism to move outward for a certain distance in the direction of the axis of the cylinder, so as to facilitate feeding and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com