Steam jet waste steam recycling device and steam jet waste steam recycling system

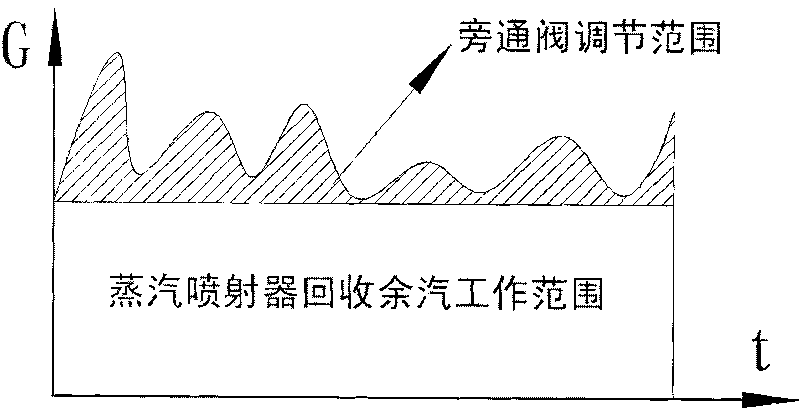

A circulating device and jet technology, which is applied in the field of residual steam recovery of steam systems, can solve the problems of difficult to achieve pressure and suction capacity, difficult to adapt to load changes, limited application scope, etc., to achieve process steam optimization, equipment The effect of expanding the load coverage and reducing the amount of bypass adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The concrete structure and working process of device and system proposed by the present invention are described in detail below:

[0034] 1. Steam recovery device with bypass:

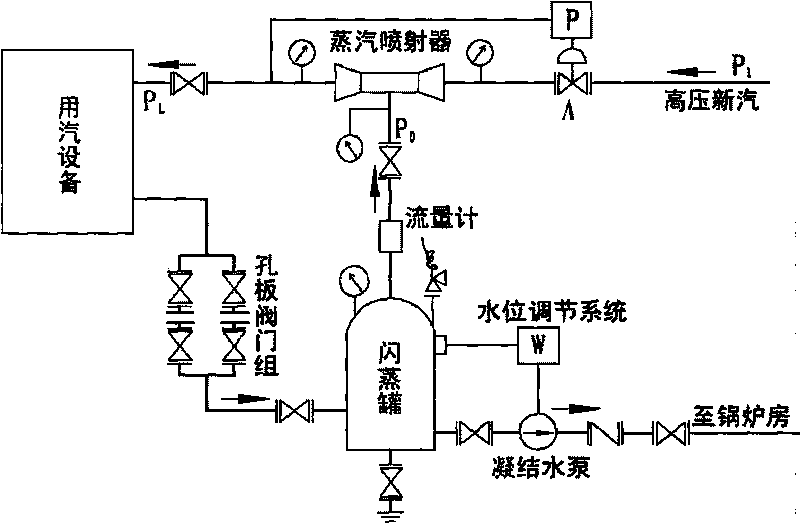

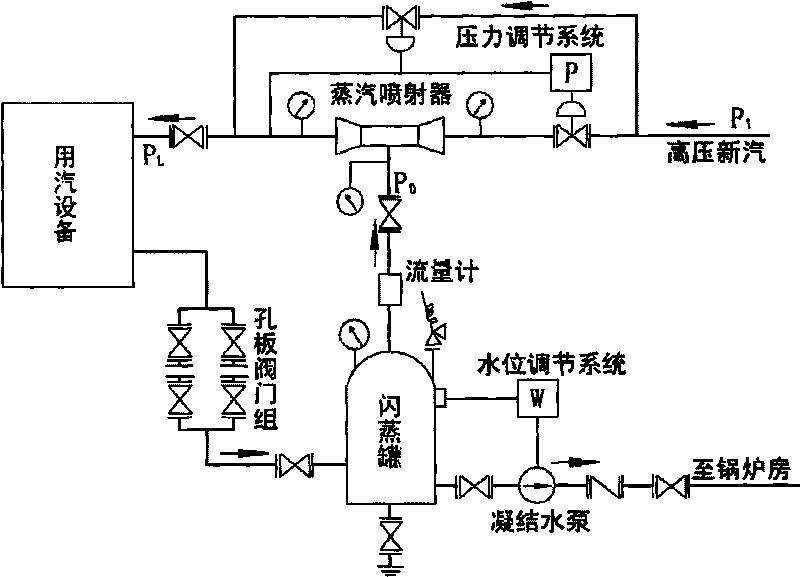

[0035] see figure 2 , the device includes a steam ejector, a process heat exchanger, an orifice valve group, a flash tank and a condensate pump connected sequentially through pipelines. The top of the flash tank connects the residual steam to the suction port of the steam ejector through the pipeline, and the steam inlet of the steam ejector is connected to the fresh steam from the heat source, and at the same time, the steam inlet end of the steam ejector is connected with a valve with a regulating valve. Bypass, the bypass is directly connected from the steam inlet end of the steam injector to its steam outlet end. The outlet pipe of the condensate pump is connected to the boiler room. The pipelines of the device are equipped with electric valves at the inlet of the steam injector, regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com