Luminaire radiator and LED luminaire with fan

A technology of LED lamps and cooling fans, applied in refractors, lighting and heating equipment, components of lighting devices, etc., can solve problems such as short service life, complex heat dissipation structure, and complex structure, and achieve a path to reduce heat dissipation and conduction , Increase the heat dissipation area, good thermal conductivity and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

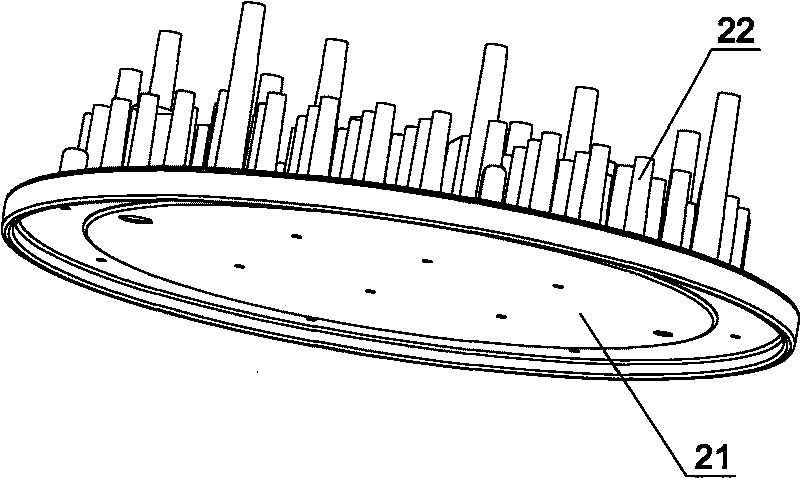

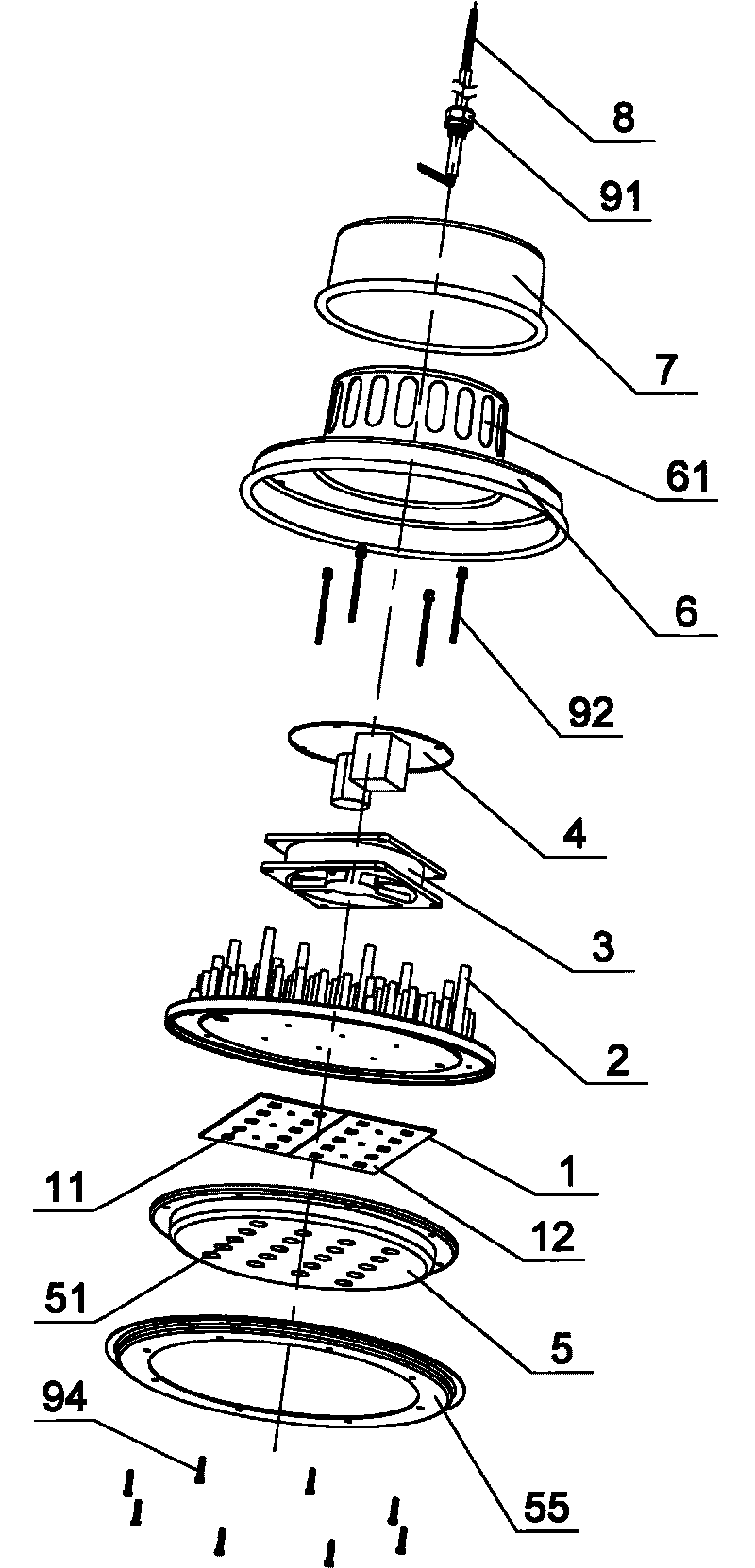

[0033] Such as Figure 1 ~ Figure 4As shown, the LED lamp with a fan in this embodiment includes an LED light source assembly 1, a lamp radiator 2, a cooling fan 3, a drive circuit board assembly 4, an optical lens 5, a decorative ring 55, an air intake cover 6, a rear cover 7, Power cord 8, waterproof bolt assembly 91; the LED light source assembly 1 includes several LED chips 11, LED heat dissipation substrate 12, the optical lens 5 is located in front of the LED light source assembly 1, and the optical lens 5 includes several A lens 51 corresponding to the LED chip 11, the decorative ring 55 is fixedly connected with the optical lens 5 and the lamp heat sink 2 through screws 94, and the optical lens 5 and the lamp heat sink are fixedly connected. 2. The peripheral shielding and covering of the bottom make the appearance simple; the lamp heat sink includes a bottom plate 21, the bottom surface of which is used for bonding the LED heat dissipation substrate 12, and the top su...

Embodiment 2

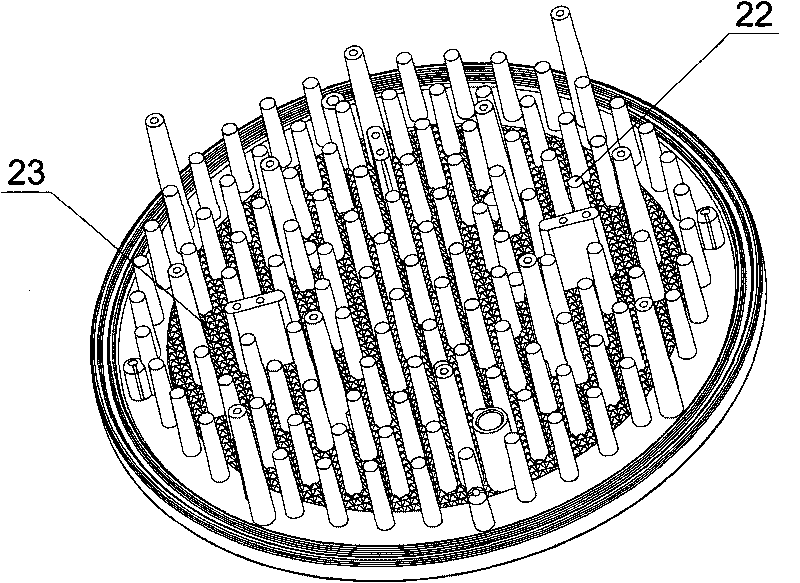

[0035] Such as Figure 5 , Image 6 As shown, the difference between this embodiment and Embodiment 1 is that: in this embodiment, the heat dissipation part 22 includes several outer heat sinks 221 located in the upper peripheral area of the bottom plate 21 and a plurality of outer heat sinks 221 located in the upper central area of the bottom plate 21 Several inner heat sinks 222, the exterior of the outer heat sink 221 is sheet-shaped and has a closed ring in the middle, air circulates through the gaps between the sheets of the outer heat sink 221, the inner heat sink 221 222 is pin columnar, the height of the inner heat sink 222 is smaller than the height of the outer heat sink 221, and the height difference between the two forms a groove space area, that is, the upper central area of the heat sink 22 is provided with a space for accommodating Place the space area of the heat dissipation fan 3 so that the heat dissipation fan 3 can be fully or partially embedded in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com