Self-cleaning fluidized bed heat exchanger

A fluidized bed heat exchanger, self-cleaning technology, applied in fluidized bed heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve the problem of no breakthrough in the gas-side convective heat transfer coefficient, etc. Achieve the effect of low cost, easy cleaning and improving heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

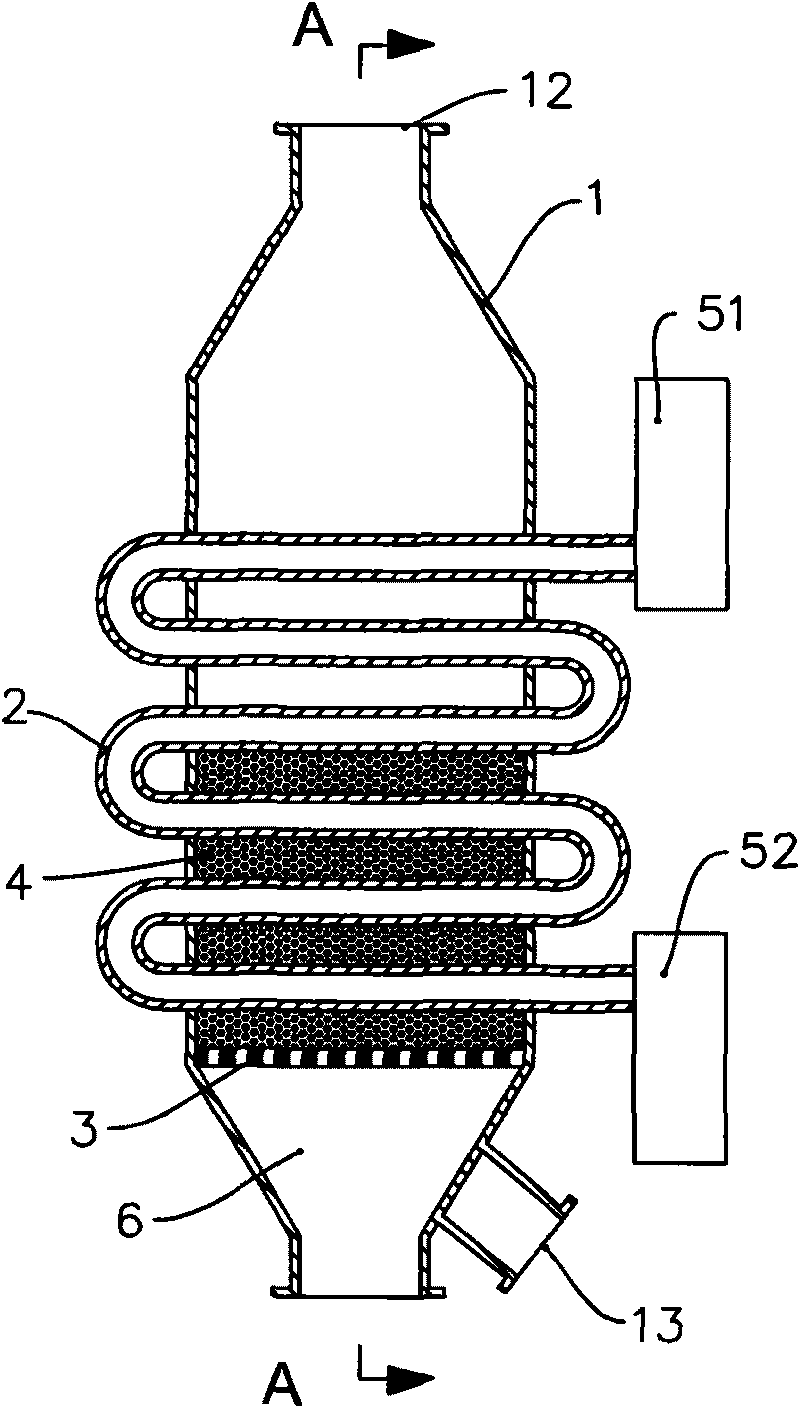

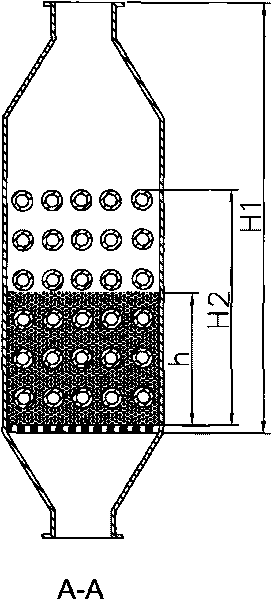

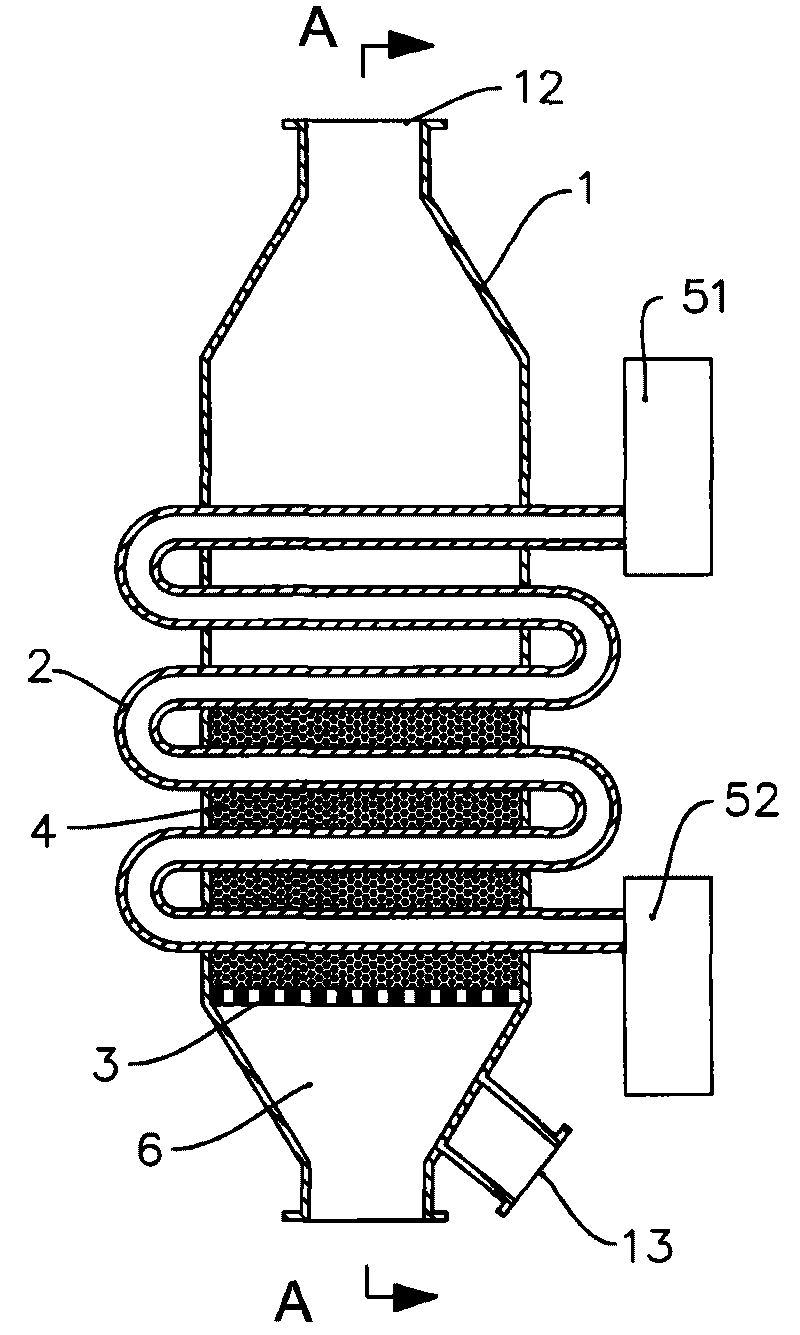

[0011] see figure 1 , the self-cleaning fluidized bed heat exchanger includes a substantially cylindrical shell 1, the air inlet 13 and the gas outlet 12 are respectively arranged at both ends of the shell 1, and dust-laden low-temperature, medium-temperature or high-temperature flue gas or Explosive gas such as coal gas enters the cylinder 1 from the air inlet 13 , and is discharged from the gas outlet 12 after exchanging heat with the heat exchange tube 2 in the cylinder 1 . The gas that enters the barrel 1 from the air inlet 13 can be any gas and any component such as flue gas or coal gas, but does not include liquid. The intake air temperature can be low, medium or high temperature. The gas predistributing plate 3 is located in the cylinder body 1 between the gas inlet 13 and the gas outlet 12 and is arranged close to the gas inlet 13 . The gas pre-distribution plate 3 is generally a flat plate, on which a plurality of through holes of equal diameter are uniformly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com