Device for testing airtightness of weld joint on ship surface and using method thereof

An inspection device and air-tightness technology, which is applied in the liquid-tightness measurement using liquid/vacuum degree, by detecting the appearance of fluid at the leakage point, ship parts, etc., can solve the difficulty of manufacturing progress and production cost control, increase Shipbuilders' repetitive labor and inspection methods can not meet the problems of segmented overall painting and quality, so as to reduce the workload and paint construction workload, and reduce the effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

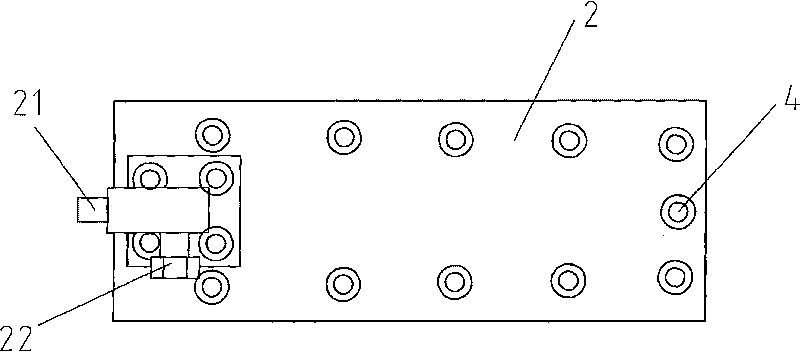

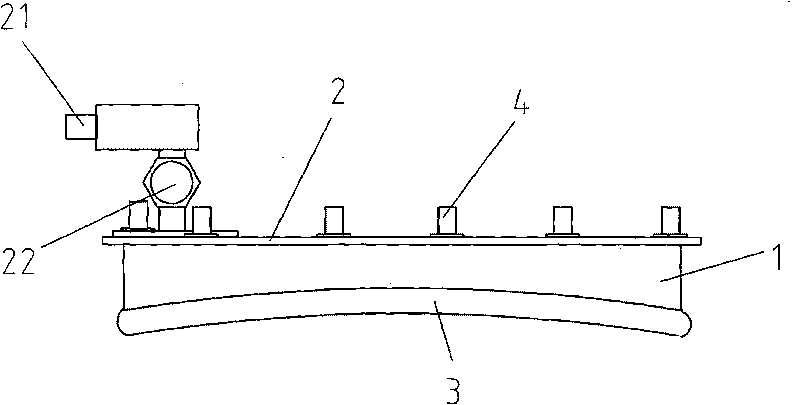

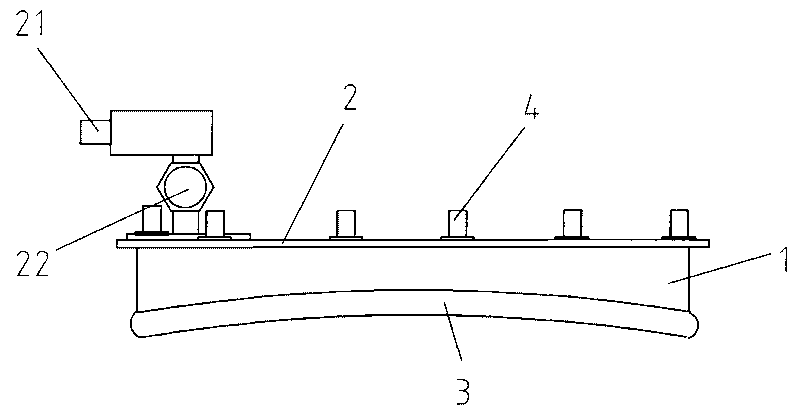

[0017] refer to figure 1 , figure 2 , an inspection device for the airtightness of welds on the curved surface of the hull, which includes an outer frame 1 whose lower end surface cooperates with the curved surface of the hull, the top of the outer frame 1 is sealed with a plexiglass plate 2, and the outer frame 1 The fixed bolt 4 is used for sealing connection with the plexiglass plate 2. Of course, other sealing connection methods can also be used according to actual needs. The lower end surface edge of the outer frame 1 is connected with a rubber strip 3, and the plexiglass plate 2 is provided with There is a vacuum nozzle 21, and a pressure gauge 22 is arranged on the vacuum nozzle 21.

[0018] How to use this product, the steps are as follows:

[0019] a) Select the inspection device that cooperates with the welding part of the lower end surface of the outer frame 1 and the curved surface;

[0020] b) Connect a vacuum pump to the vacuum nozzle 21 of the inspection dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com