Metal building element dynamic wind load simulation test device

A technology for building components and simulation tests, which is used in the testing, measuring devices, instruments, etc. of machine/structural components, which can solve the problems of low efficiency, large investment, and limited detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

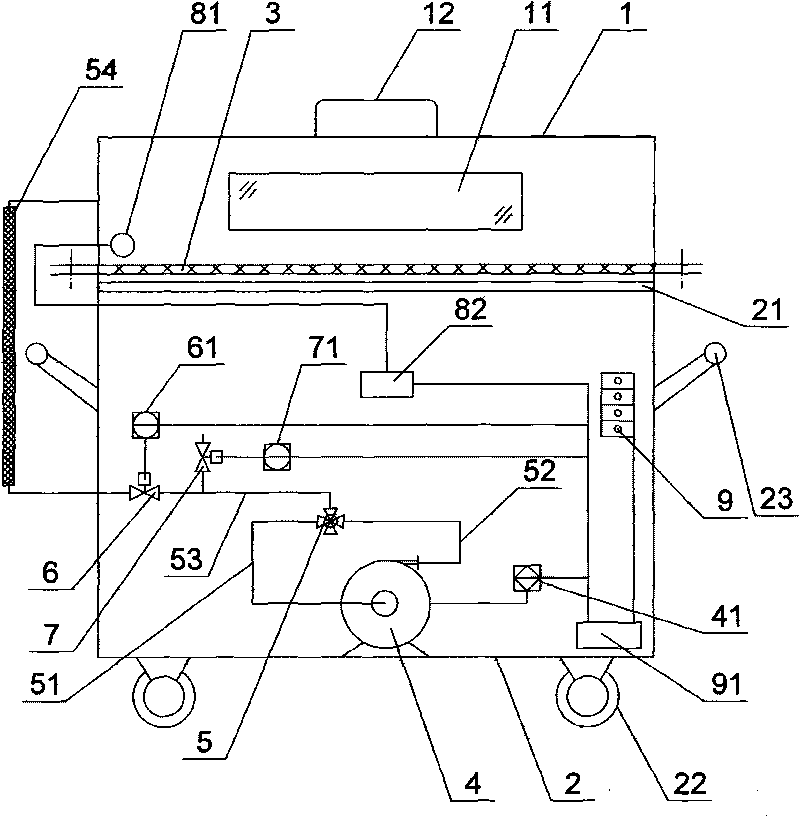

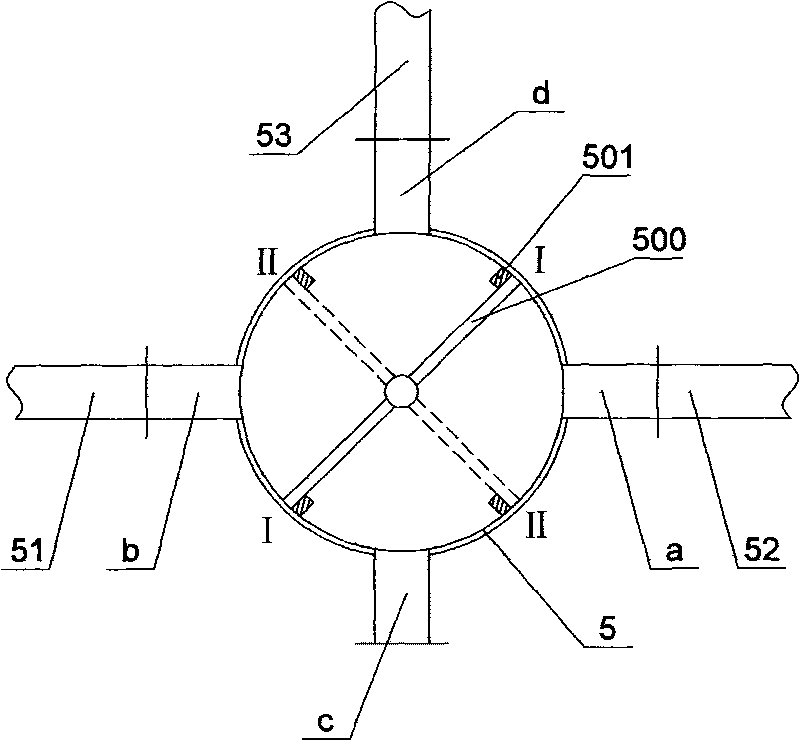

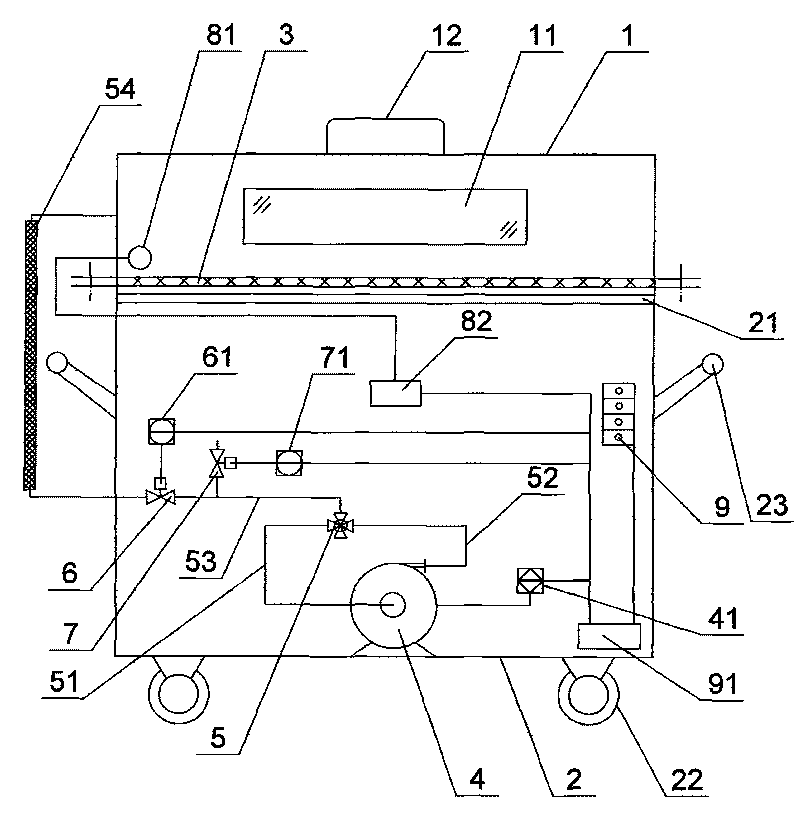

[0021] Such as figure 1 , figure 2 As shown, the present invention includes an upper box body 1, a lower box body 2, a blower fan 4, a reversing valve 5, a wave valve 6, a regulating valve 7, and a control device, between the upper box body 1 and the lower box body 2 A seal 3 for sealing the upper box 1 is provided, and an observation window 11 is provided on the upper box 1, so as to observe the component test state in the upper box 1, and the top of the upper box 1 A handle 12 is provided for easy installation and disassembly; the top of the lower box 2 is provided with a support device 21 for supporting the test piece, and the side of the lower box 2 is provided with a push rod 23, and the lower box 2 Casters 22 are provided at the bottom of the bottom, so that the whole device is easy to move; a reversing device 500 is arranged in the valve body of the reversing valve 5, and the reversing valve 5 includes a valve air inlet a, a valve air outlet b, a first valve in and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com