PEA space charge test device capable of testing conductive current

A technology of space charge and conduction current, applied in the direction of measuring current/voltage, measuring device, measuring electrical variables, etc., can solve the problem of linking the conduction current and space charge for research, etc., to eliminate surface current, eliminate influence, avoid The effect of coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

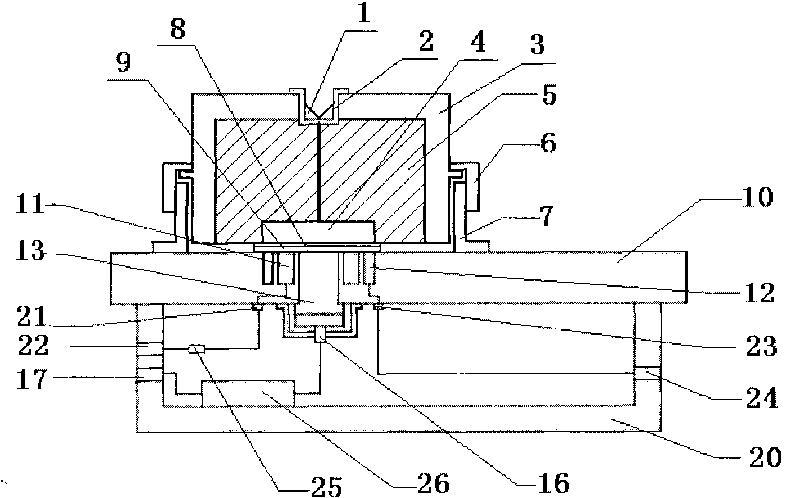

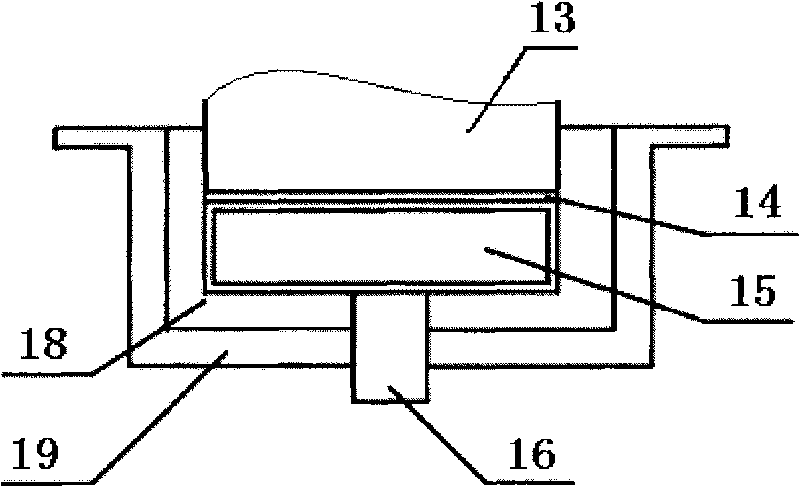

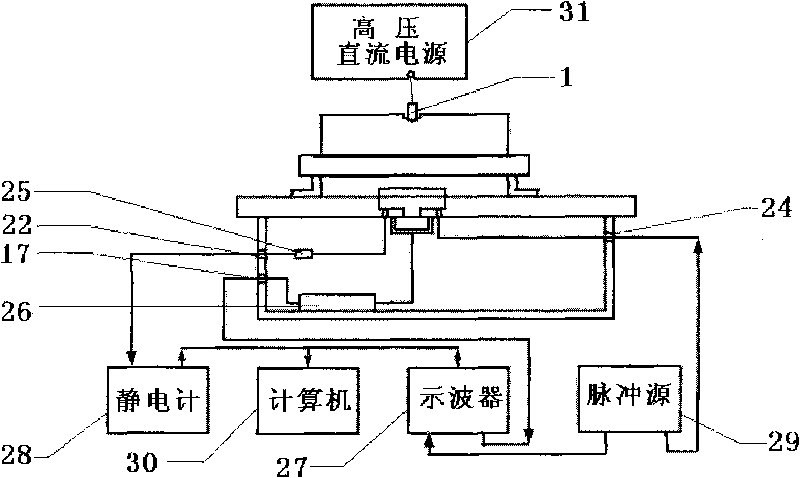

[0031] The present invention will be further described below by way of examples. figure 1 It is a schematic diagram of the electrode structure of the embodiment, which consists of five parts, namely the upper electrode, the lower electrode, the space charge collection channel, the current signal collection channel and the pulse input channel.

[0032] The high-voltage BNC socket 1 is set in the insulating rubber ring 2 and fixed in the center hole of the cylindrical upper electrode metal shell 3. The upper electrode center electrode 4 is placed in the upper electrode metal shell 3. The lower surface of the upper electrode center electrode 4 is in contact with the The lower end surface of the upper electrode metal shell 3 is in the same plane, the upper surface of the upper electrode center electrode 4 is connected with the inner conductor of the high-voltage BNC socket 1 with a bare wire, epoxy resin 5 is poured inside the upper electrode metal shell 3, and the upper electrode ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com