Method for processing open-web sharp-angled rhomboid tube

A processing method and rhomboid technology are applied in the processing field of hollow sharp-angle rhomboid pipes, which can solve problems such as the processing of the corners of pipes, and achieve the effect of ensuring welding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

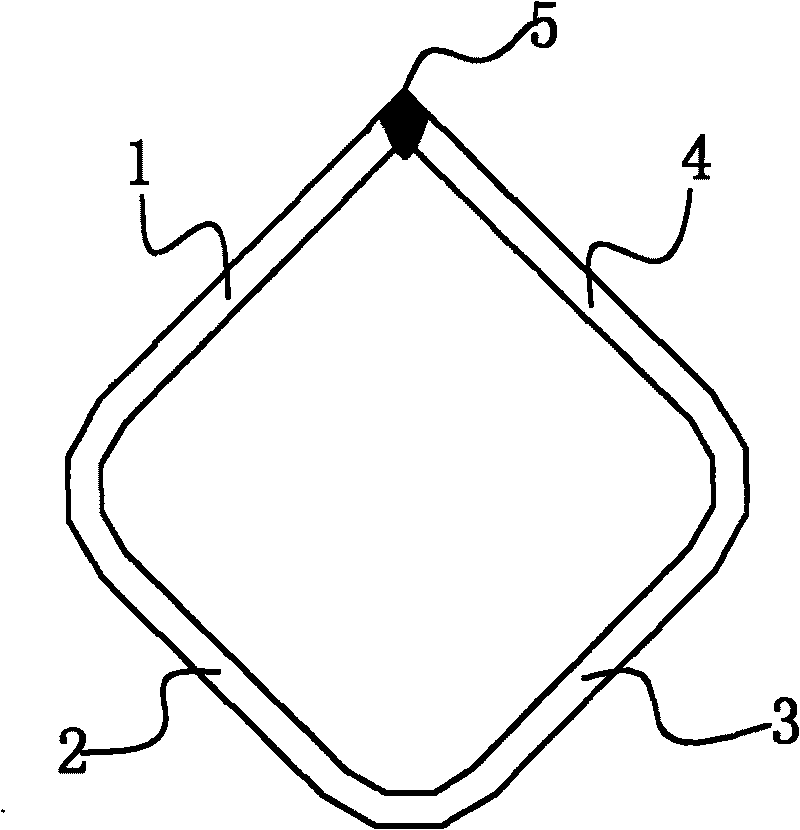

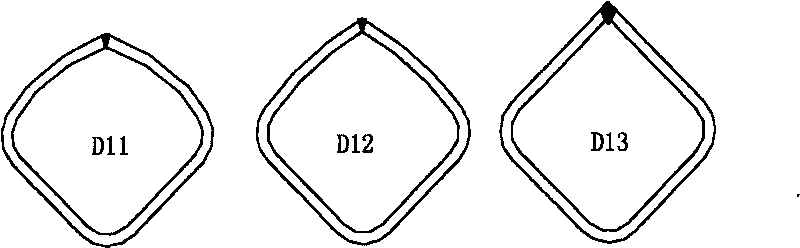

[0027] Such as figure 1 As shown, the four sides 1, 2, 3, and 4 of a sharp-edged rhomboid tube on an empty stomach are all planes, one corner 5 of which is a sharp corner, and the remaining three corners are rounded corners, and the butt welding seam is located on the sharp corner 5 .

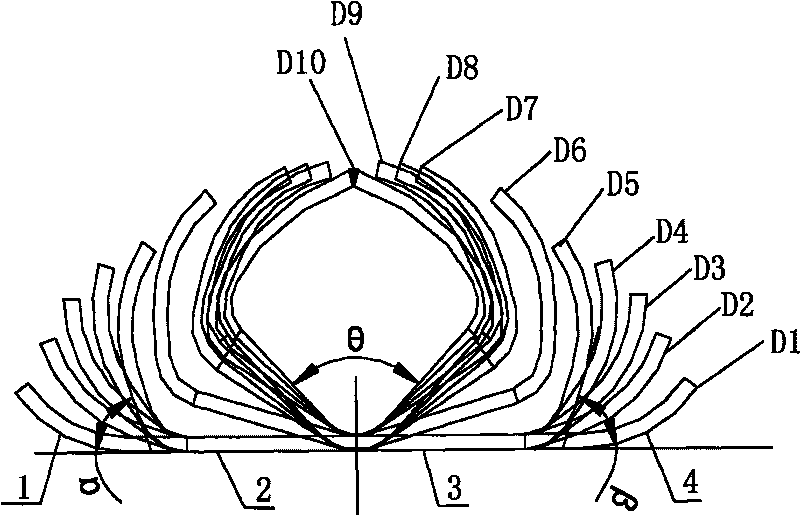

[0028] The processing method of the present invention will be described in detail below by taking a fasting sharp-angled rhomboid tube in which the included angles between the four sides are all 90° as an example.

[0029] Using steel strips as raw materials, placed horizontally, first processed with a horizontal rolling mill.

[0030] Such as figure 2 As shown, in the first pass D1, rolls are used to roll the areas corresponding to the first side 1 and the fourth side 4 on both sides of the steel strip, so that the areas near the outside of the first side and the fourth side become arc-shaped surfaces. The width of the shape does not exceed the length of a single side of the product. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com