High-precision workbench and processing method thereof

A workbench and high-precision technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of unsuitable control of precision, high production cost, and heavy labor, and achieve the solution of mechanical vibration, low cost, good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

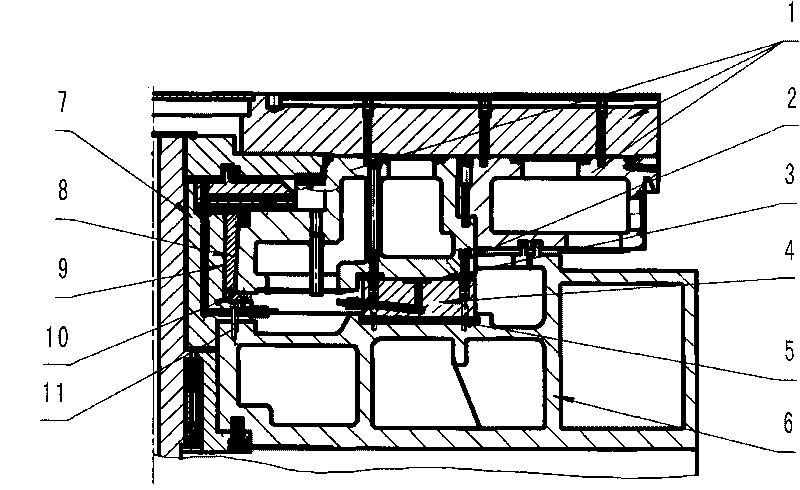

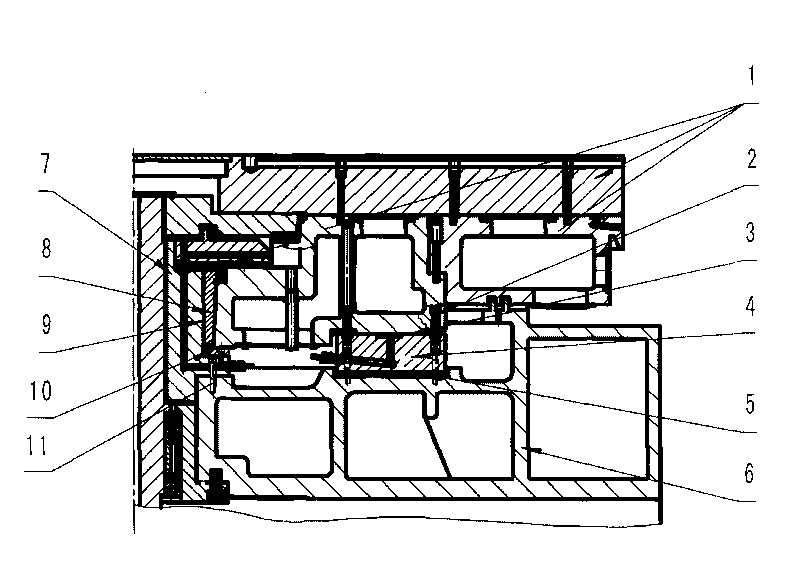

[0020] see figure 1 , The main shaft hydrostatic oil film 9 is set between the hydrostatic bearing bush 8 on the workbench 1 and the main shaft 7, this part is the key to ensure the radial runout accuracy of the workbench. The static pressure oil film 3 of the guide rail ring of the worktable is set between the worktable 1 and the guide rail ring 4, and this part is the key to ensure the runout accuracy of the end surface of the worktable. Between the guide rail ring 4 and the workbench base 6 is a high-precision guide rail positioning glue 5 , which is the key to solving the assembly accuracy of the guide rail ring 4 and the workbench base 6 .

example 2

[0022] Processing method of the present invention is as follows:

[0023] 1. Match the static pressure bearing bush 8 with the workbench 1 according to the taper, and the contact area reaches more than 85%, and install it in the taper hole of the workbench, and fasten it with screws.

[0024] 2. Use the guide rail ring and 4 and workbench 1 to check that the contact area of the static pressure oil film 3 of the guide rail ring of the workbench reaches more than 85%, and check that the joint surface of the positioning ring 6 and the joint research workbench 1 are parallel to the 3 places of the static pressure oil film of the guide rail ring of the workbench After the angle is not greater than 0.005mm, fasten the guide rail ring 4 and the workbench 1 with the bolt 2 for the process.

[0025] 3. Put the main shaft 7 on a high-precision cylindrical grinding machine, and prepare the main shaft hydrostatic oil film 9 according to the static pressure bearing bush 8 of the worktabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com