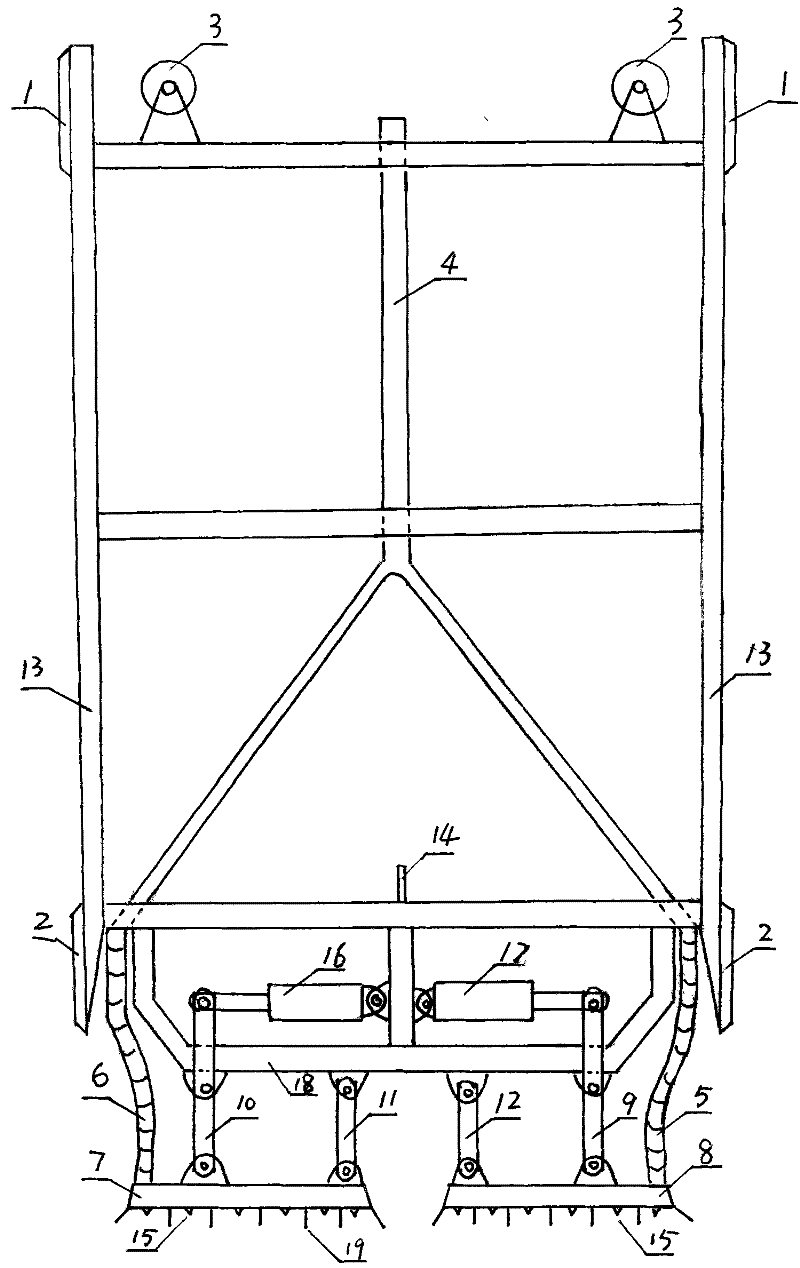

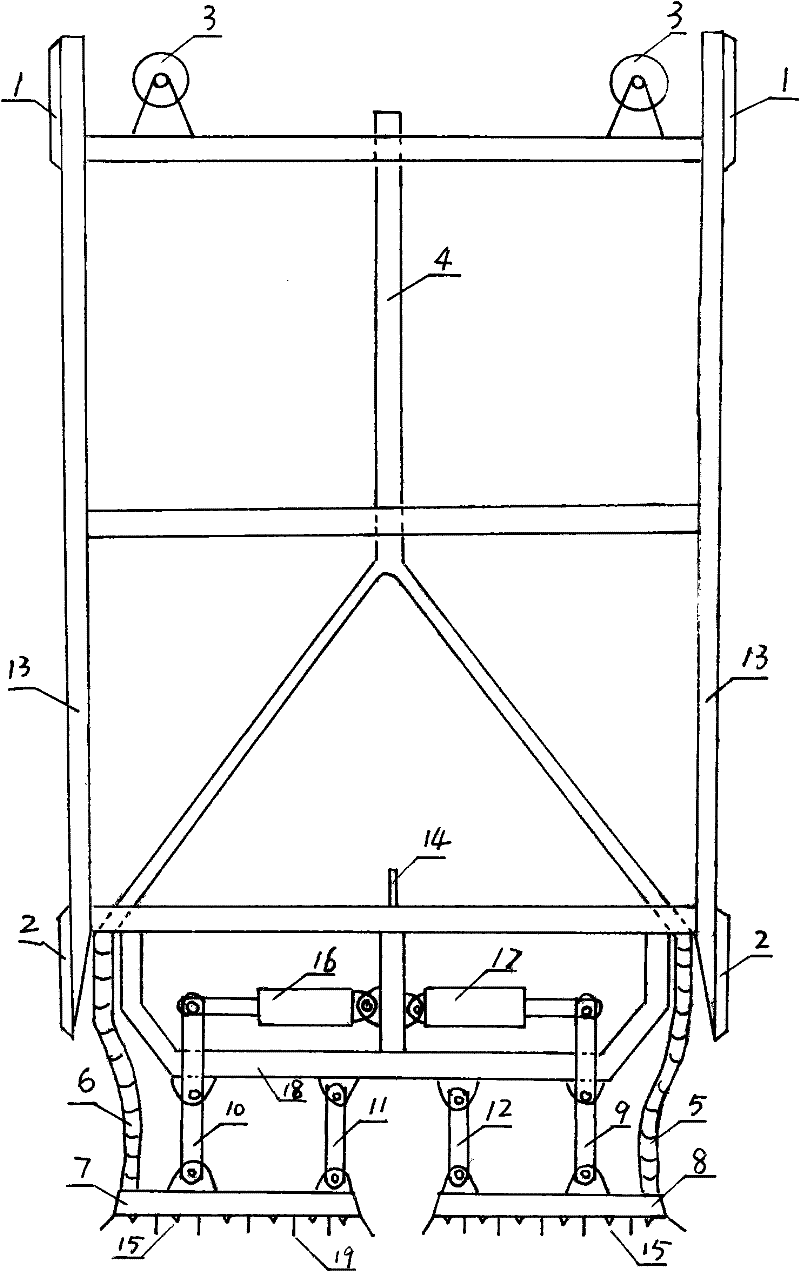

Double-cylinder hydraulic grooving machine

A grooving machine and hydraulic technology, which is applied to earth moving machines/shovels, water conservancy projects, artificial islands, etc., can solve the problems of high maintenance cost, slow grooving speed, low efficiency, etc., and achieves strong power reliability, Simple structure and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0013] Accompanying drawing is a kind of specific embodiment of the present invention, advances by following several below:

[0014] 1. Deviation correction system

[0015] The deviation correction system is composed of two upper deviation correction plates 1, two lower deviation correction plates 2, an inclinometer 14 at the middle position, and two groups of arms on the frame. At the beginning of grooving, because the grooving machine is partly on the ground, its vertical guidance is completed by two groups of arms on the frame. There are two hydraulic rectifying plates on the left and right sides of the machine, which can be adjusted to the verticality of the machine.

[0016] 2. Slurry supply system

[0017] The slurry supply system is supplied by a high-pressure mud pump. The slurry is divided into two branches after passing through the water inlet pipe. One enters the tool holder A through the water inlet hose A, and the slurry is injected from several water nozzles on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com