Equipment for testing gas tightness of weapon sight and method thereof

An air tightness and gun sighting technology, which is applied in the direction of measuring the acceleration and deceleration rate of the fluid and using the liquid/vacuum degree for liquid tightness measurement, etc. problems, to save test time, shorten test cycle, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

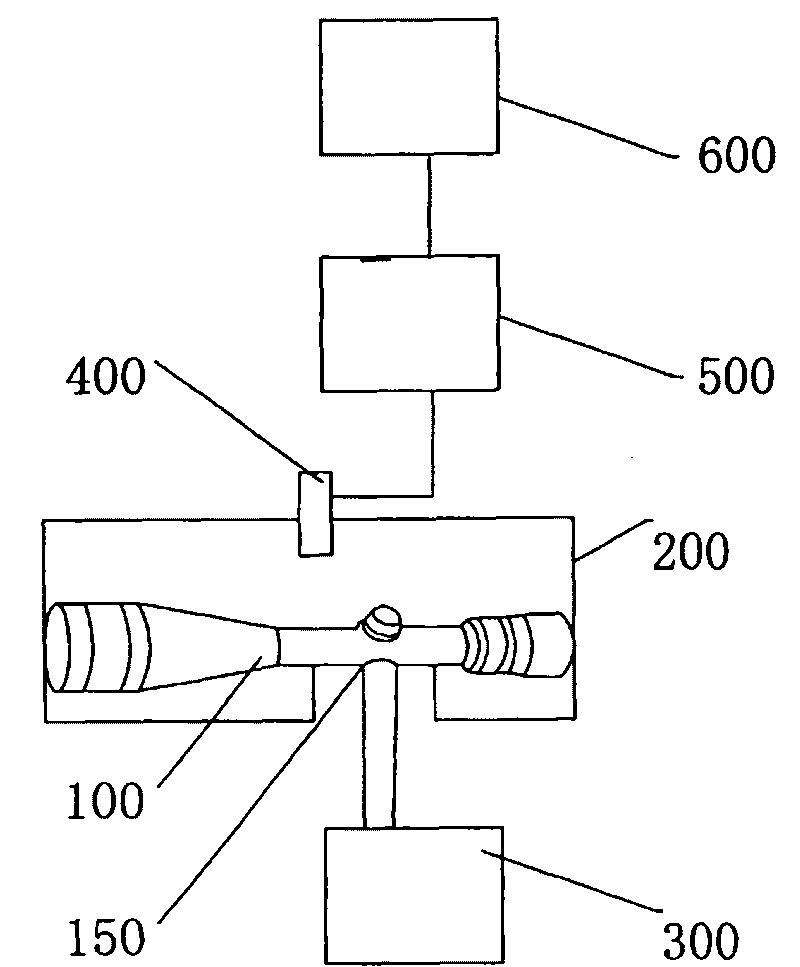

[0028] The invention provides a device for testing the airtightness of gun sights, the principle of which is as follows: figure 2 As shown, the device includes: a sealing component 200 , a gas source device 300 , a pressure sensing device 400 , an analysis device 500 and a display device 600 .

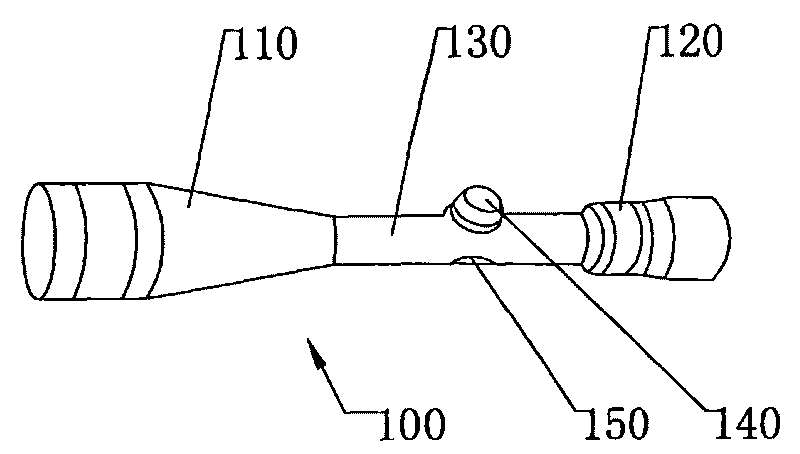

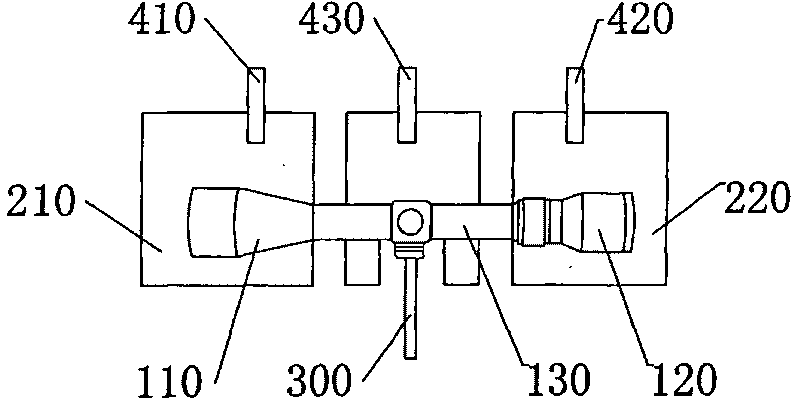

[0029] The sealing part 200 is used to seal the seams of the rifle scope 100, and the seams are the parts where airtight defects may appear on the rifle scope 100, such as the eyepiece section 110, the objective lens section 120 and the middle knob section 130, and the seams The position does not include the air hole 150 of the gun sight 100 . The sealing in this embodiment includes: the opening and closing cover parts constituting the main body, and the sealing rings arranged between and inside the opening and closing cover parts. The opening and closing cover is provided with a gap that matches the section of the gun sight 100. When the gun sight 100 is placed in the opening and cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com