Portable crystallizer vibration amplitude and horizontal oscillation measuring system of continuous caster

A crystallizer vibration and horizontal swing technology, applied in the configuration of indicating equipment/measuring equipment, casting equipment, manufacturing tools, etc., can solve problems such as inability to carry out targeted maintenance and lack of crystallizer vibration devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

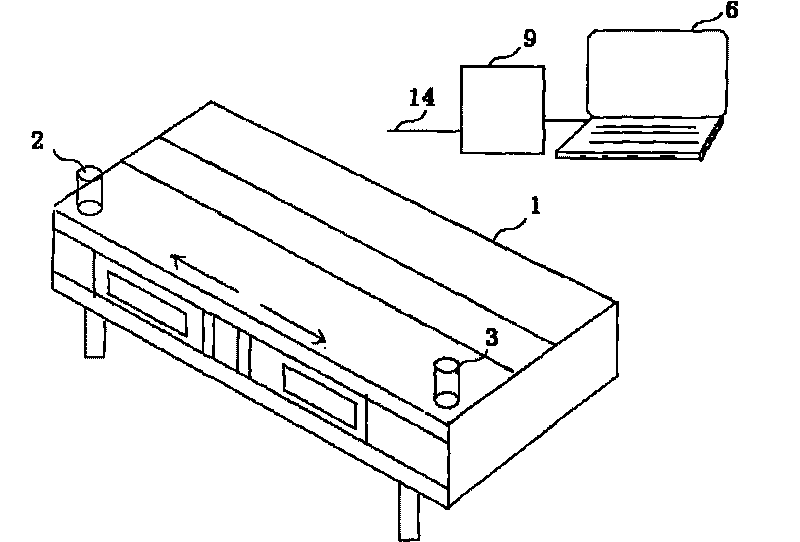

[0027] Such as figure 1 As shown, the portable continuous casting machine crystallizer amplitude and horizontal swing measurement system includes at least a vertical displacement sensor, a horizontal displacement sensor and a processing and analysis unit 6. Two low-frequency vertical displacement sensors are installed on the crystallizer vibration platform 1 along the length direction. One vertical displacement sensor 2, the second vertical displacement sensor 3, the vibration signals given by the first vertical displacement sensor 2 and the second vertical displacement sensor 3 are filtered by the anti-interference filter 7, and sent to 24-bit A / D converter 8 for analog-to-digital conversion, after the first vertical displacement sensor 2 and the second vertical displacement sensor 3 undergo analog-to-digital conversion through the 24-bit A / D converter 8, they are collected by the dynamic signal collector 9 and sent to the processing and analysis unit 6 for analysis and proces...

Embodiment 2

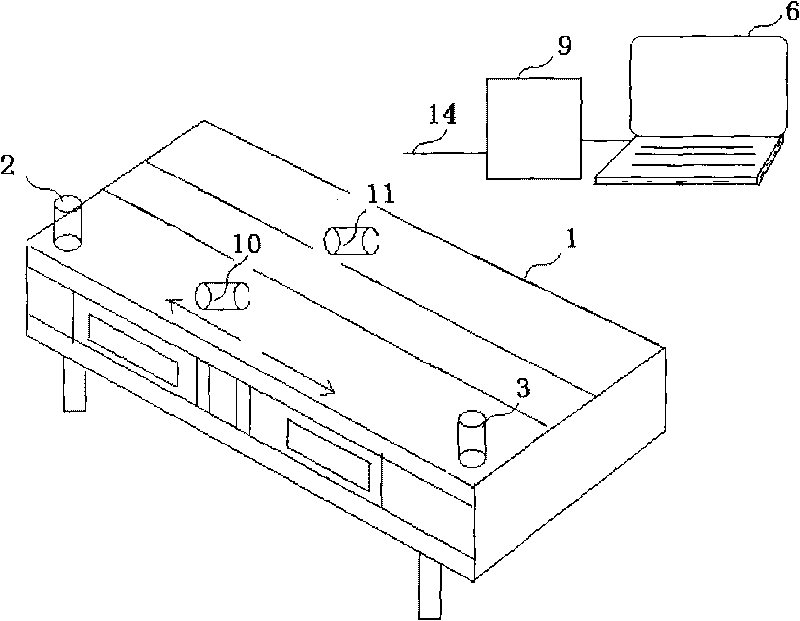

[0038] Such as figure 2As shown, the portable continuous casting machine crystallizer amplitude and horizontal swing measurement system includes at least a vertical displacement sensor, a horizontal displacement sensor and a processing and analysis unit 6. Four low-frequency displacement sensors are installed on the crystallizer vibration platform 1. The first vertical displacement sensor 2 and the second vertical displacement sensor 3, the first horizontal displacement sensor 10, the second horizontal displacement sensor 11; the first vertical displacement sensor 2, the second vertical displacement sensor 3 and the first horizontal displacement sensor 10, the second horizontal displacement sensor 11 The given vibration signal is filtered by the anti-jamming filter 7, sent to the 24-bit A / D converter 8 for analog-to-digital conversion, and after the analog-to-digital conversion by the 24-bit A / D converter 8, the dynamic signal collector 9 Collect and send to analysis unit 6 f...

Embodiment 3

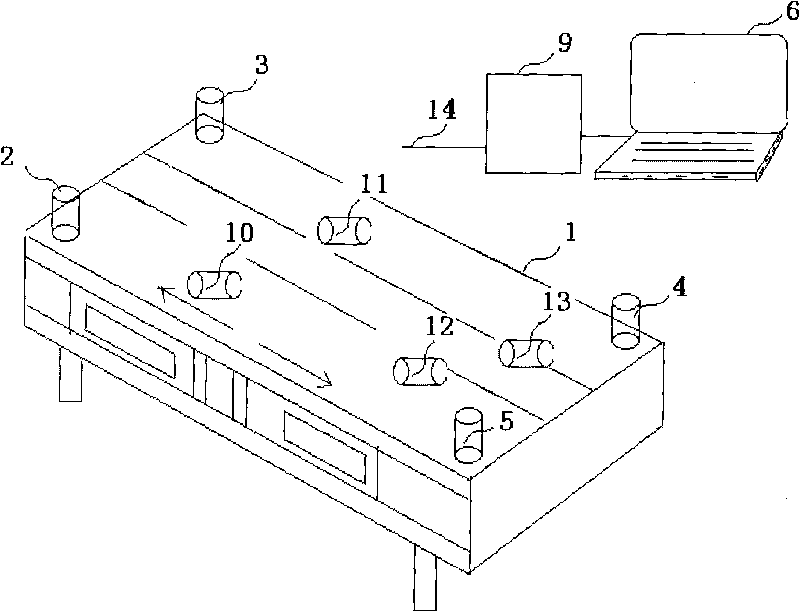

[0040] Such as image 3 As shown, the portable continuous casting machine crystallizer amplitude and horizontal swing measurement system includes at least a vertical displacement sensor, a horizontal displacement sensor and a processing and analysis unit 6. Eight low-frequency displacement sensors are installed on the crystallizer vibration platform 1, and the first vertical displacement sensor 2 , the second vertical displacement sensor 3, the third vertical displacement sensor 4, the fourth vertical displacement sensor 5 and the first horizontal displacement sensor 10, the second horizontal position sensor 11, the third horizontal displacement sensor 12 and the fourth horizontal displacement sensor 13, The first vertical displacement sensor 2, the second vertical displacement sensor 3, the third vertical displacement sensor 4, the fourth vertical displacement sensor 5 and the first horizontal displacement sensor 10, the second horizontal displacement sensor 11, the third hori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com