Method for carrying out plate-shaped closed-loop control by adopting plate-shaped simulation system by continuous annealing unit

A technology of simulation system and continuous annealing unit, which is applied in the field of metallurgy, can solve the problems that the shape change cannot be improved through the corresponding control system, and the continuous annealing unit cannot be equipped with flatness measuring rollers and corresponding control systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

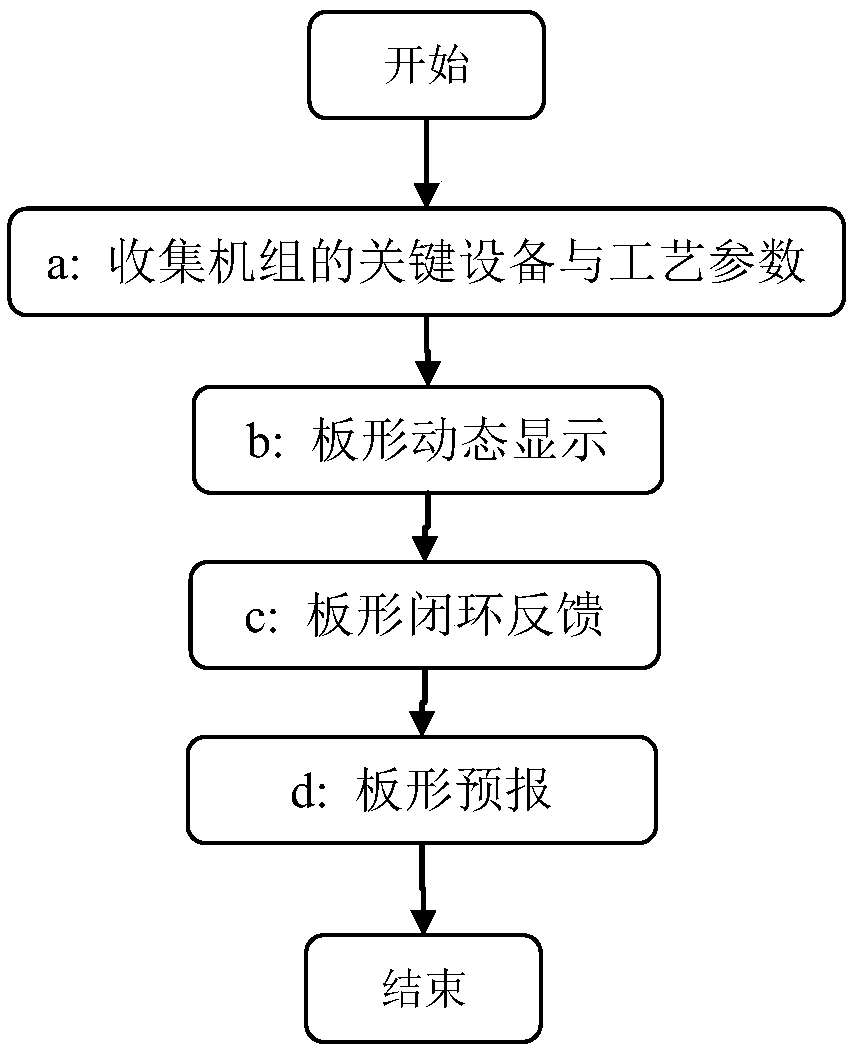

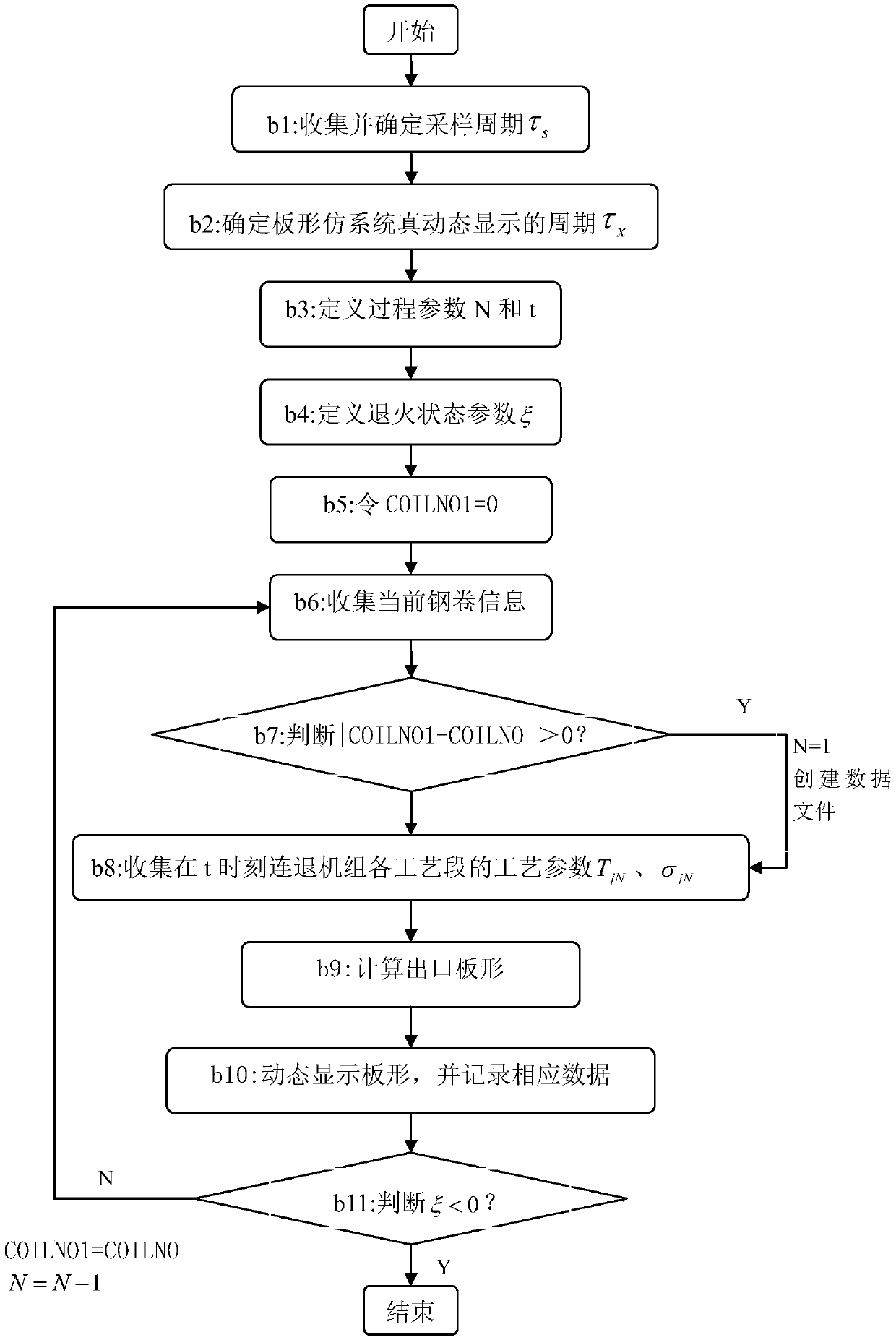

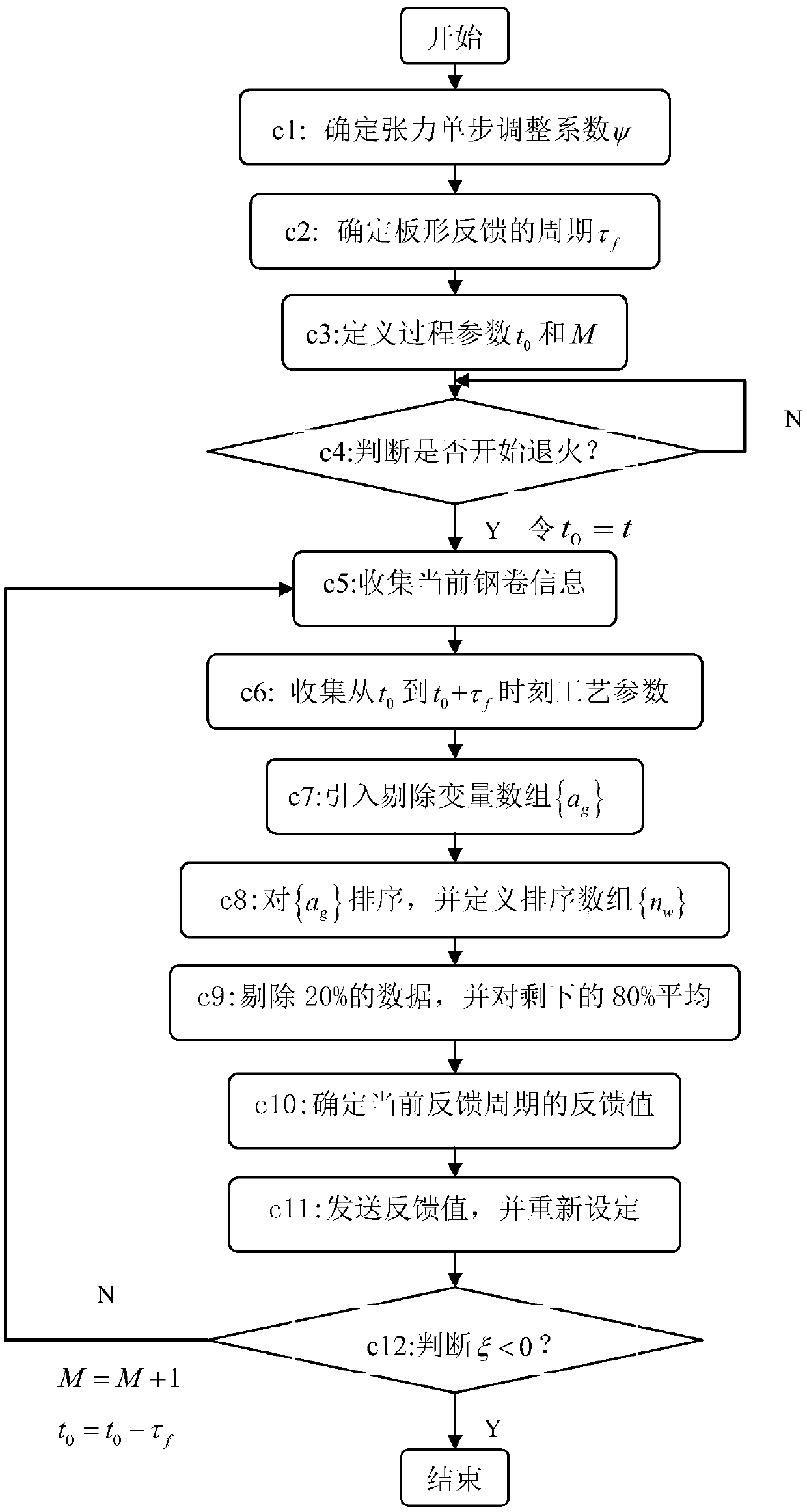

[0083] Taking the use of the plate shape simulation system by a continuous annealing unit in a domestic steel mill as an example, combined with figure 1 , the method of using the flatness simulation system to carry out flatness closed-loop control in the continuous annealing unit is described in detail, and the specific steps are as follows:

[0084] (a) Collect the key equipment and process parameters of the unit, mainly including: the total number of process sections in the furnace of the continuous annealing unit is 7, and they are numbered 1···7 in sequence, and the maximum value of tension σ set in each process section is collected j,max ={8.3,6.9,7.3,7.1,10.3,10.5,12.3}(MPa) and minimum value σ j,min ={7.7,6.2,6.4,6.3,9.5,9.7,11.5} (MPa), furnace roll body curve D(x) 1 ={448.71,448.85,449,449.14,449.28, 449.43,449.57,449.72,449.86,450,450,450,450,450,450,450 449.86,449.72,449.57,449.43,449.28,449.14,449,448.85,448.71 }, D(x) 2 ={449.29, 449.40, 449.51, 449.62, 449.72, ...

Embodiment 2

[0128] Taking the use of the flatness simulation system by a continuous annealing unit in a domestic steel mill as an example, the flatness simulation system is used for the continuous annealing unit to perform flatness closed-loop control. The specific steps are as follows:

[0129] (a) Collect the key equipment and process parameters of the unit, mainly including: the total number of process sections in the furnace of the continuous annealing unit is 7, and they are numbered 1···7 in sequence, and the maximum value of tension σ set in each process section is collected j,max ={8.3,6.9,7.3,7.1,10.3,10.5,12.3}(MPa) and minimum value σ j,min ={7.7,6.2,6.4,6.3,9.5,9.7,11.5} (MPa), furnace roll body curve D(x) 1 ={448.71,448.85,449,449.14,449.28, 449.43,449.57,449.72,449.86,450,450,450,450,450,450,450 449.86,449.72,449.57,449.43,449.28,449.14,449,448.85,448.71 }, D(x) 2 ={449.29, 449.40, 449.51, 449.62, 449.72, 449.83, 449.94, 450, 450, 450, 450, 450, 450, 450, 450, 450, 450, 450...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com