Vehicle moving-magnet follow-up steering headlight system

A follow-up steering and magnetic technology, applied in vehicle components, optical signals, signal devices, etc., can solve the problems of complex structure, easy failure, and high manufacturing cost, and achieve reliable safety performance, low cost, and small space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

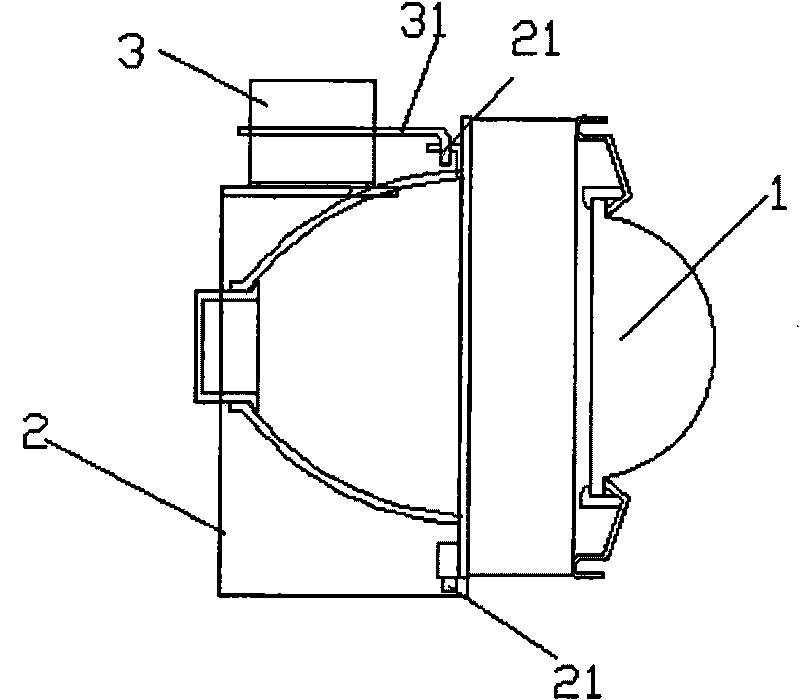

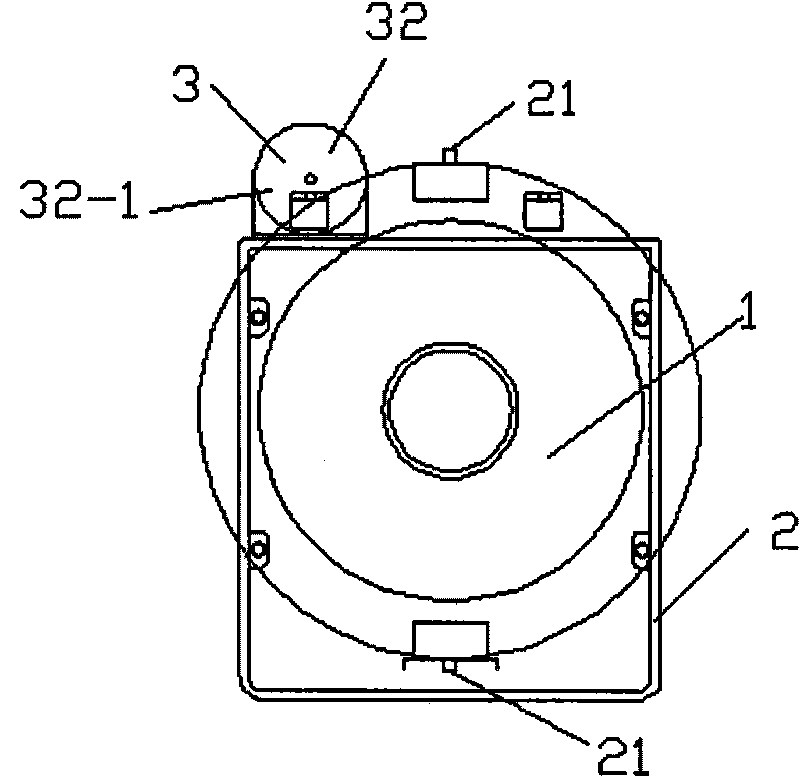

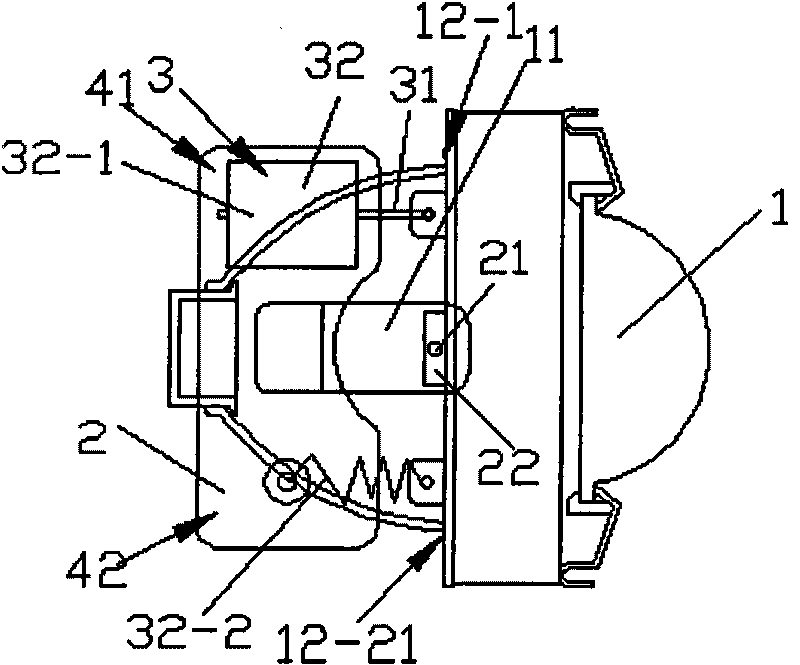

[0021] like Figure 1 to Figure 3 As shown, the vehicle magnetic follow-up steering headlight system of the present invention includes a lamp 1, a bracket 2 and a power mechanism 3, and the bracket 2 is a fixing frame for fixing the lamp 1 and the motor mechanism 3. A connecting plate 11 is arranged on the upper and lower sides of the frame, and a connecting piece 22 is arranged on the upper and lower ends of the lamp 1 respectively. A swingable structure is formed on the bracket 2 . The above-mentioned power mechanism 3 includes a single solenoid valve power mechanism 32 with a pull rod 31 . The power mechanism 3 is fixedly installed on the bracket 2 to form a linkage structure with the lamp 1 . The single solenoid valve power mechanism 32 is made up of a solenoid valve 32-1 and a spring 32-2. The solenoid valve 32-1 is fixed on one side 41 of the bracket 2, and is connected to one side 12-1 of the lamp 1 by a pull rod 31; one end of the spring 32-2 is fixed on the other sid...

Embodiment 2

[0025] like Figure 4 and Figure 5 As shown, in the magnetic follow-up steering headlight system for vehicles of the present invention, the two solenoid valve power mechanisms 33 are composed of two solenoid valves 33-1, and the power of the two solenoid valves 33-1 is reversed. In this direction, the solenoid valves 33-1 are fixedly installed on both sides of the bracket 2, and the pull rods 31 of the two solenoid valves 33-1 are respectively connected to the two sides of the lamp 1 to form a two-way swing structure. All the other are the same as embodiment one. The structure of the car's magnetic follow-up headlight system is when turning, two car lights turn at the same time, one solenoid valve 33-1 is the thrust, and the other solenoid valve 33-1 is the pull force, so as to achieve the follow-up steering of the car lights. Function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com