Polypropylene nano composite material and preparation method thereof

A nano-composite material, polypropylene technology, applied in the field of polypropylene nano-composite materials, can solve the problems of losing the advantages of nano-composite materials, difficulty in dispersion, performance degradation, etc., and achieve the effect of improving material performance, improving dispersion effect, and reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 39% of polypropylene, 40% of Cloisite 15A, 20% of maleic anhydride grafted polypropylene, 0.25% of Irganox1010, 0.25% of Igrafos 168, and 0.5% of Negonox DSTP in a high-speed mixer. After 5 minutes, add it to the twin-screw extruder to melt and extrude to granulate. The temperature inside the screw barrel is: 180°C in the first zone, 190°C in the second zone, 190°C in the third zone, 190°C in the fourth zone, 200°C in the machine head, double The rotating speed of the screw extruder is 600 rpm, and the clay masterbatch M40 is obtained.

Embodiment 2

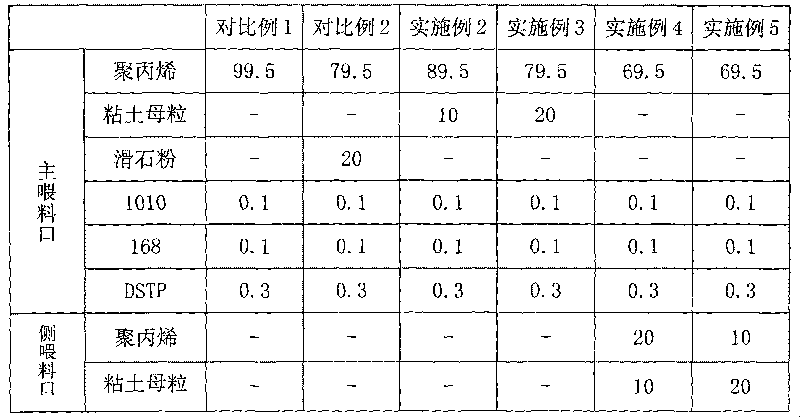

[0039] Take by weight 89.5% of polypropylene, the clay masterbatch M40 that embodiment 1 makes is 10%, Irganox 1010 is 0.1%, Igrafos 168 is 0.1%, Negonox DSTP is 0.3%, dry mixes 5 in high-speed mixer Minutes, then add to the twin-screw extruder to melt and extrude to granulate, wherein the temperature in the screw barrel is: 180°C in the first zone, 190°C in the second zone, 190°C in the third zone, 190°C in the fourth zone, 200°C in the head, twin-screw The extruder rotational speed was 600 rpm. After the particles are dried, they are injection molded on an injection molding machine to prepare samples.

Embodiment 3

[0041] Take by weight 79.5% of polypropylene, the clay masterbatch M40 that embodiment 1 makes is 20%, Irganox 1010 is 0.1%, Igrafos 168 is 0.1%, Negonox DSTP is 0.3%, dry mix in high-speed mixer After 5 minutes, add it to the twin-screw extruder to melt and extrude to granulate. The temperature in the screw barrel is: 180°C in the first zone, 190°C in the second zone, 190°C in the third zone, 190°C in the fourth zone, 200°C in the head, and double The screw extruder rotating speed is 600 rpm. After the particles are dried, they are injection molded on an injection molding machine to prepare samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com