Wall panel component and preparation method thereof

A technology of wall panels and components, applied in covering/lining, construction, building construction, etc., which can solve problems such as high labor costs and inconvenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

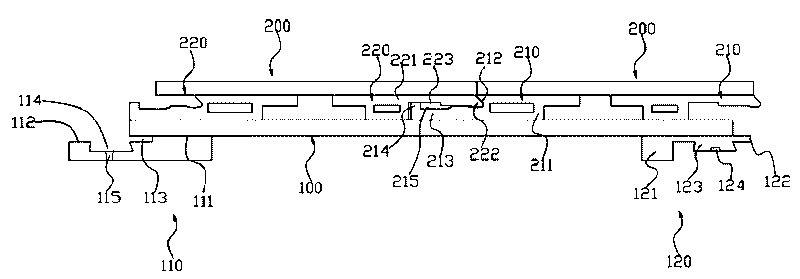

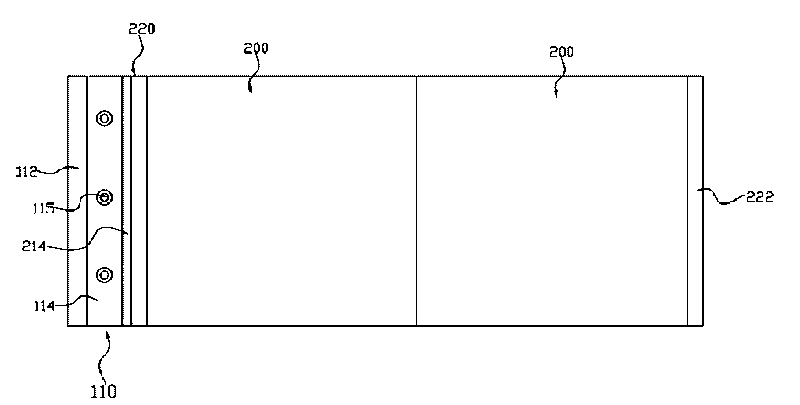

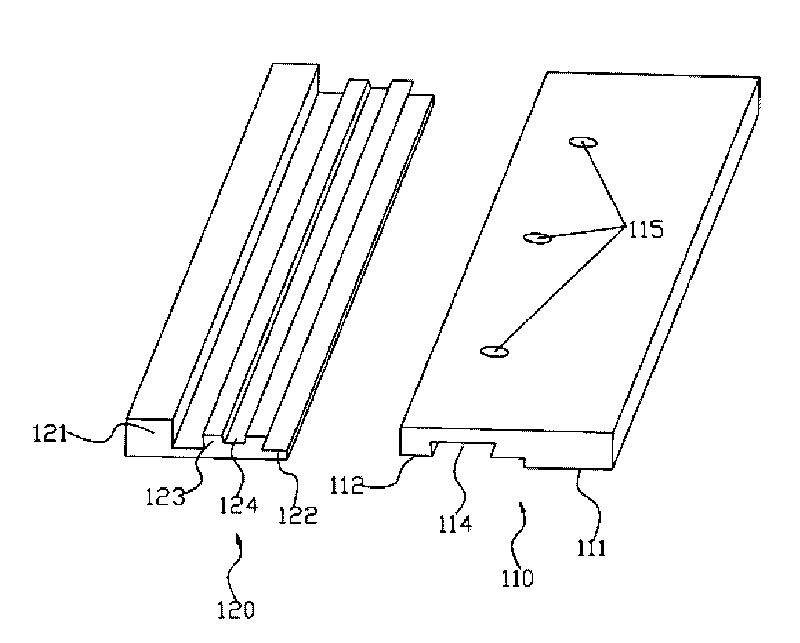

[0033] Please check figure 1 , figure 2 , which respectively depict a schematic diagram of a wall panel assembly. A wall panel assembly includes a base plate 100 and two wall panels 200 . The perimeter of these wall panels 200 after splicing is equal to the perimeter of the base plate 100, and the perimeter of these wall panels 200 after splicing is interlaced with the perimeter of the base plate 100. The distance from the left side of the periphery of the substrate 100 is equal to the distance from the right side of the periphery of the spliced wall panels 200 to the right side of the periphery of the substrate 100 . In this embodiment, it is taken that the wall panel assembly includes two wall panels as an example, but it is not limited thereto. Other wall panel assemblies including 5 or 10 wall panels, for example, are applicable to this embodiment.

[0034] The base plate 100 can be a wood board or a plastic board or a honeycomb board or a fireproof board, which is g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com