Inner rotor type radiator fan

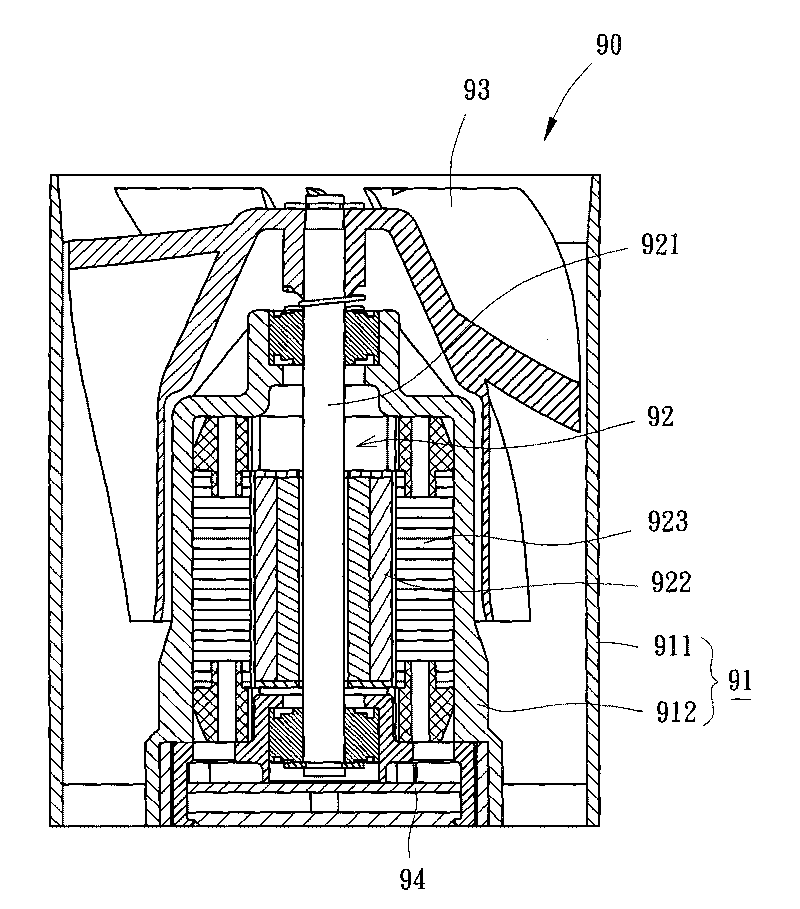

A heat dissipation fan and rotor type technology, applied in the direction of non-variable pumps, electromechanical devices, electrical components, etc., can solve the problem that the motor shell 912 cannot provide magnetic sealing effect, reduce the heat dissipation effect of the heat dissipation fan 90, and affect the operation efficiency of the impeller 93, etc. problem, to achieve the effect of improving the overall heat dissipation effect, improving the heat dissipation effect, and avoiding magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to allow the above-mentioned and other objects, features and advantages of the present invention to be more clearly understood, the preferred embodiments of the present invention will be specifically cited below, together with the accompanying drawings, and described in detail as follows:

[0046] Please refer to Figure 4 and Figure 5 As shown, the inner rotor cooling fan according to the first embodiment of the present invention mainly includes a fan frame 1 , a magnetic shell 2 , an inner rotor motor 3 , an impeller 4 and a circuit board 5 . The fan frame 1 can be produced by means of injection molding; the magnetic sealing case 2 is combined inside the fan frame 1; the inner rotor motor 3 is arranged inside the magnetic sealing case 2; the impeller 4 is connected to the inner rotor motor 3; The circuit board 5 is electrically connected to the inner rotor motor 3 . Thereby, the circuit board 5 can be used to control the inner rotor motor 3 to drive the im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com