In-service transformer-station concrete component load-bearing safety detection device and detection method thereof

A technology for safety testing and substations, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as limited quantity, difficulty in obtaining standard core samples for compressive strength tests, and restrictions on direct detection of steel bars.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

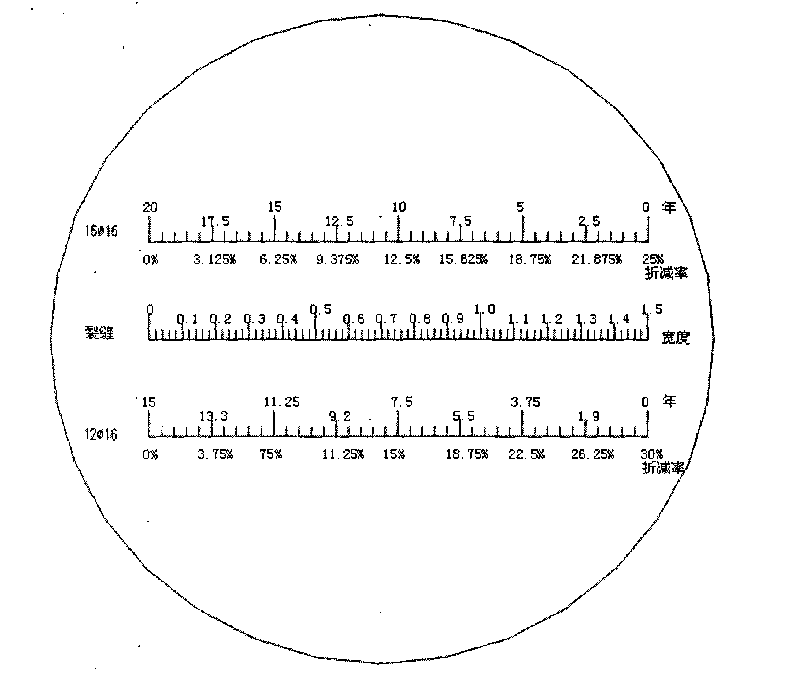

[0019] figure 1 It expresses the readable content of the multi-mark scale lens. The basic scale is the crack width mark, and the maximum scale is 1.5mm. Relevant scale marking lines, below the crack scale table are related scale marking lines corresponding to the bearing strength, failure rate and remaining safe life of the 12 φ16 ring members of longitudinal reinforcement, and the scale value of each grid is based on the crack width and bearing capacity of the corresponding member The functional relationship between loss and safety life is calculated and determined, and it is fabricated on the relevant lens through glass production processes such as etching.

[0020] figure 2 It is a scale lens embedded in the plexiglass cover. According to the concrete strength and reinforcement conditions, corresponding scale lenses are made for the limited types ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com