System and method for detecting solid strength of mass concrete

A technology for mass concrete and strength detection, applied in the field of building construction, can solve problems such as structural damage, use restrictions, and inability to apply in a large area, and achieve the effect of eliminating influence, convenient and timely detection, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

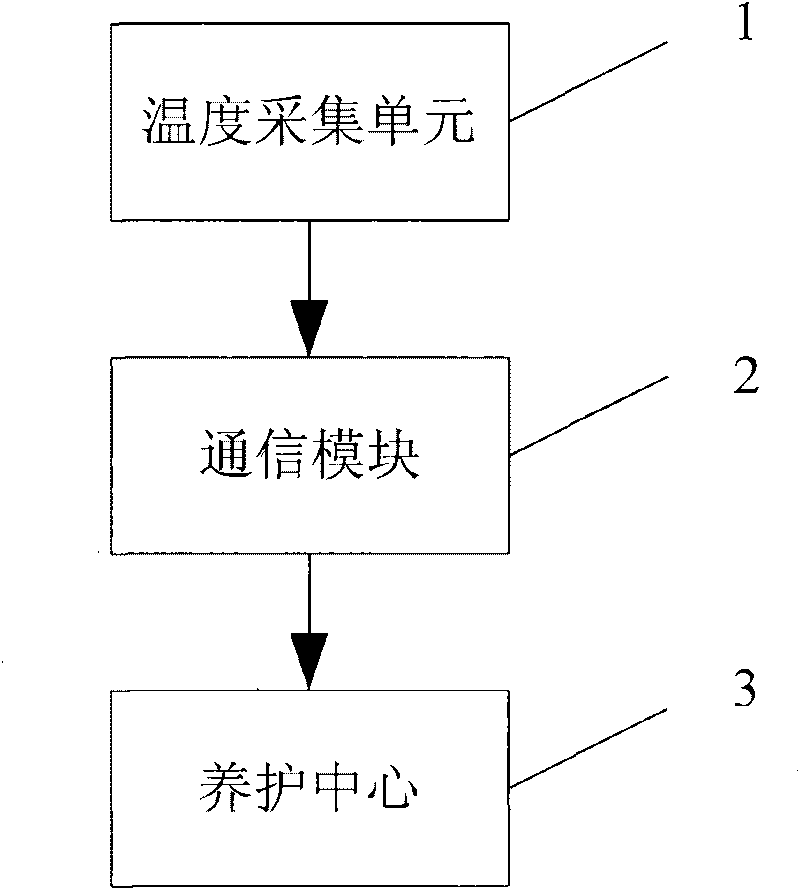

[0042] Embodiment one, see figure 1 .

[0043] The invention provides a large-volume concrete entity strength detection system, comprising:

[0044] The temperature acquisition unit 1 is used to detect the internal temperature of the mass concrete;

[0045] The communication module 2 connected to the output end of the temperature acquisition unit is used to transmit the temperature data detected by the temperature unit 1;

[0046] The maintenance center 3 connected to the output end of the communication module 2 is used to receive the temperature data transmitted by the communication module 2, perform real-time variable temperature maintenance on the concrete test block according to the temperature data, and detect the physical strength of the concrete test block.

[0047] After the temperature acquisition unit 1 detects the internal temperature of the mass concrete, the communication module 2 sends the internal temperature of the mass concrete to the maintenance center 3, a...

Embodiment 2

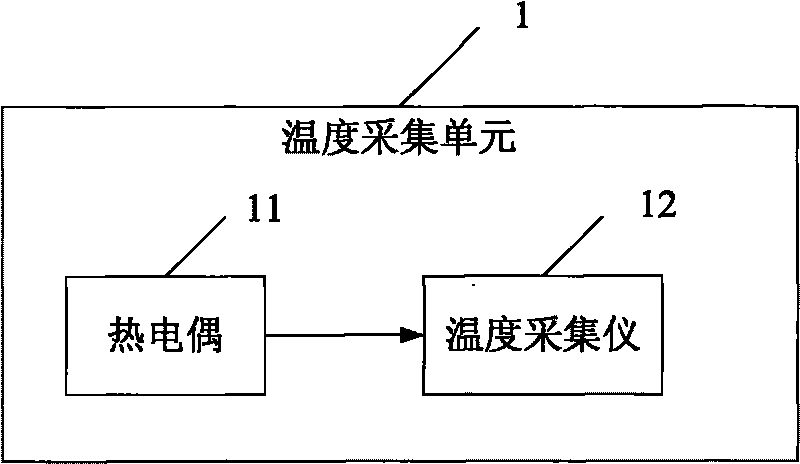

[0050] Embodiment two, see figure 2 .

[0051] The present invention also provides a large-volume concrete entity strength detection system, which is similar to the first embodiment above, and on the basis of the first embodiment, the temperature acquisition unit 1 includes:

[0052] The thermocouple 11 embedded in the mass concrete structure is used to detect the temperature inside the mass concrete;

[0053] The temperature acquisition instrument 12 connected to the thermocouple 11 and located outside the mass concrete is used to acquire the internal temperature data of the mass concrete.

[0054] In this embodiment, the thermocouple 11 pre-embedded inside the mass concrete detects the temperature condition inside the mass concrete, and sends the temperature condition to the temperature acquisition instrument 12 connected thereto, and the temperature acquisition instrument 12 receives the temperature condition The temperature data inside the mass concrete structure is sor...

Embodiment 3

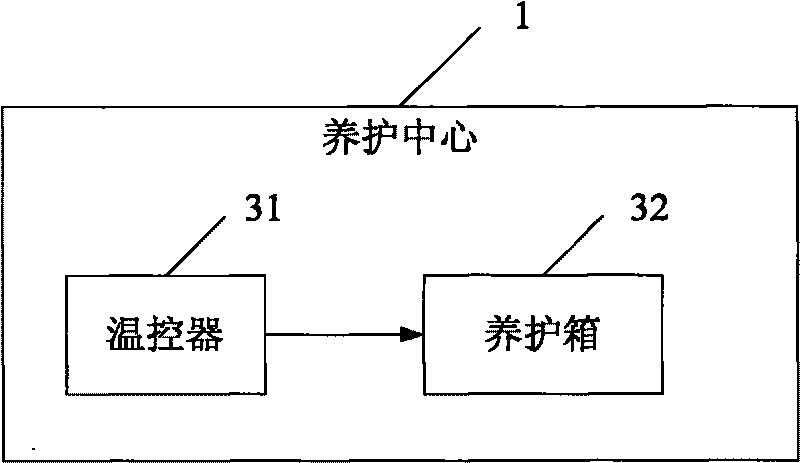

[0056] Embodiment three, see image 3 .

[0057] The present invention also provides a large-volume concrete entity strength detection system, which is similar to the first embodiment above, and on the basis of the first embodiment, the maintenance center 3 includes:

[0058] The curing box 31 is used for temperature-varying curing of the concrete test block;

[0059] The temperature controller 32 connected to the curing box 31 is used for receiving the temperature data transmitted by the temperature acquisition unit and controlling the temperature of the curing box 31 according to the temperature data.

[0060] During the detection process, after the temperature controller 32 receives the temperature data transmitted by the temperature acquisition unit, it controls the temperature of the curing box 31 connected with the temperature controller according to the received temperature data, so that the temperature of the curing box 31 is the same as the temperature inside the mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com