Trailer type horizontal loop

A trailer-mounted and horizontal technology, applied in bending workpieces, metal processing equipment, metal rolling, etc., can solve the problems of damaged belt phenomenon steel plate, plate and belt flutter, large length of flexible transmission parts, etc. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

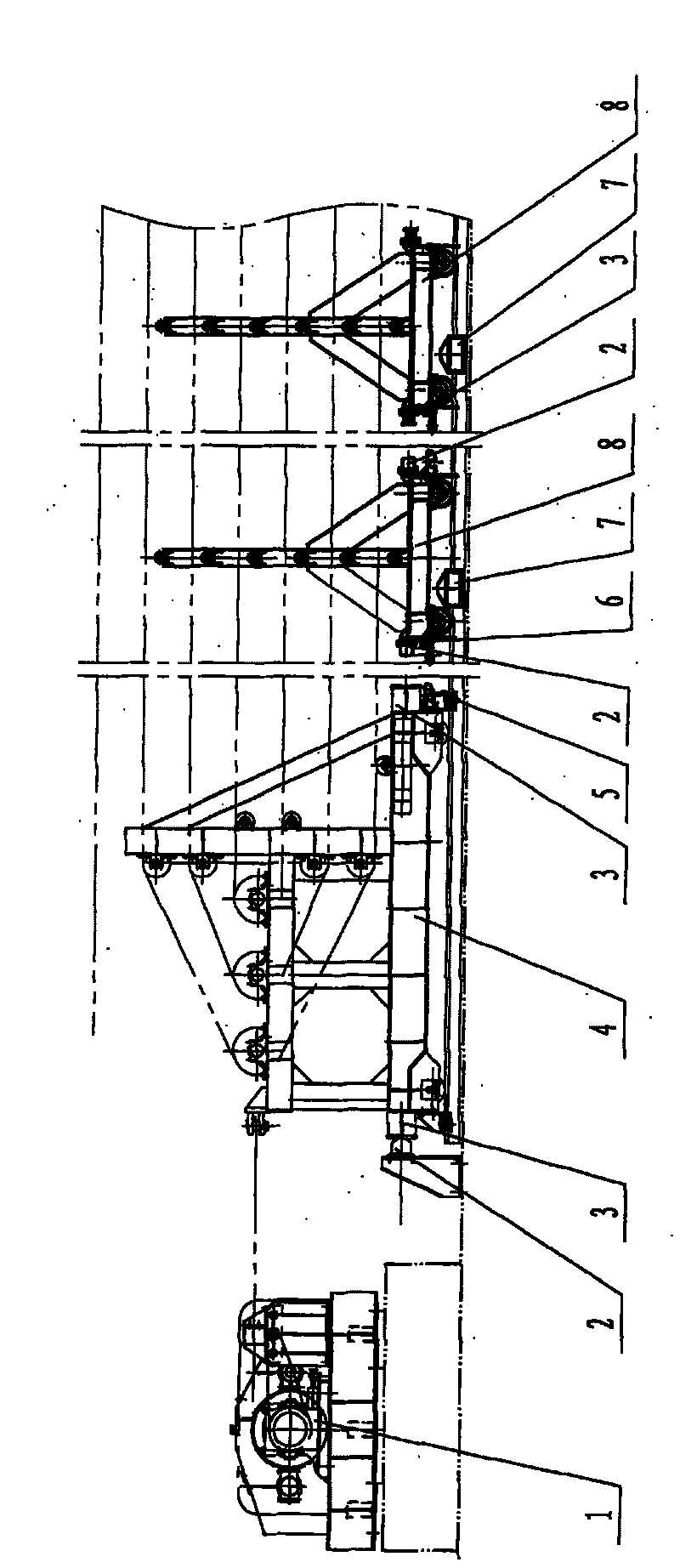

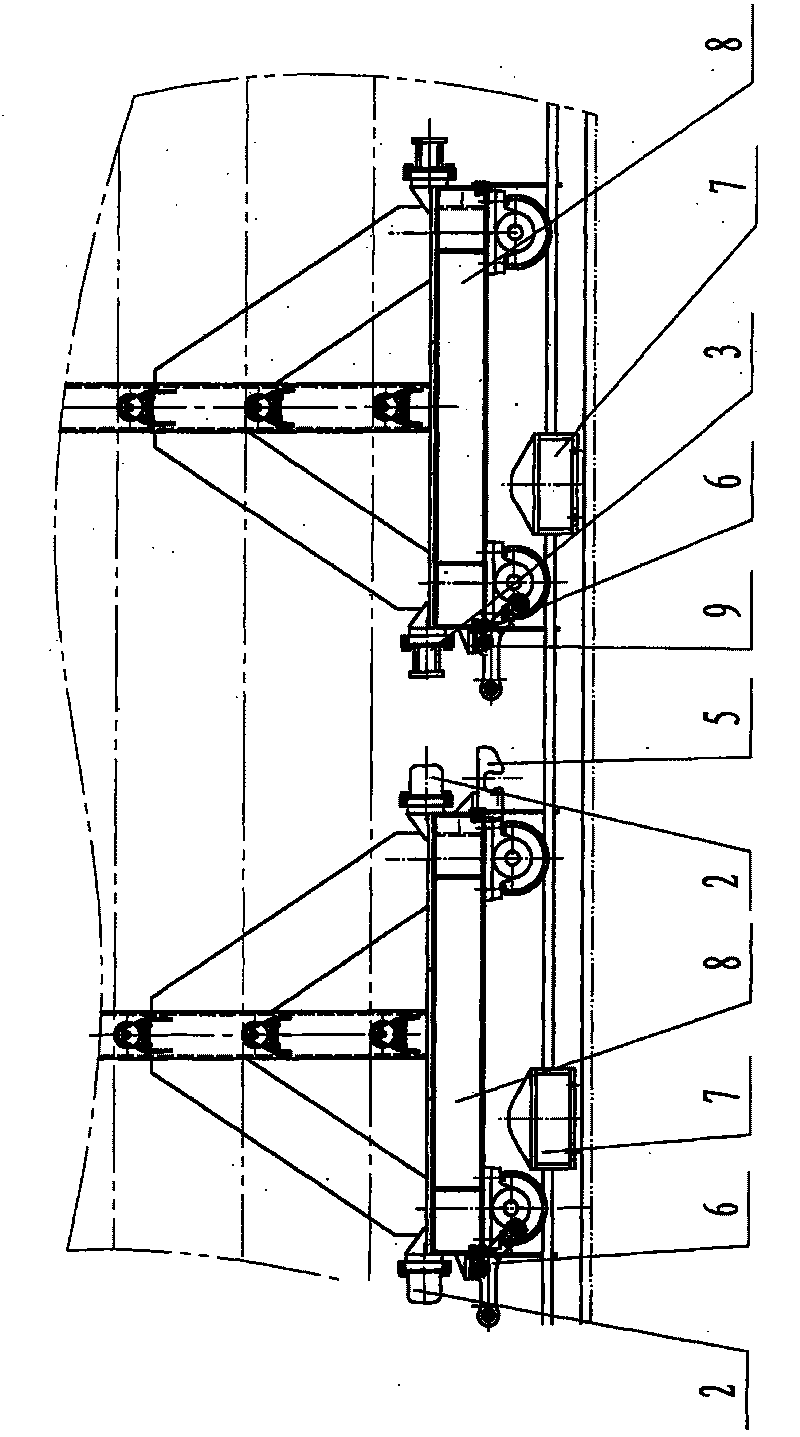

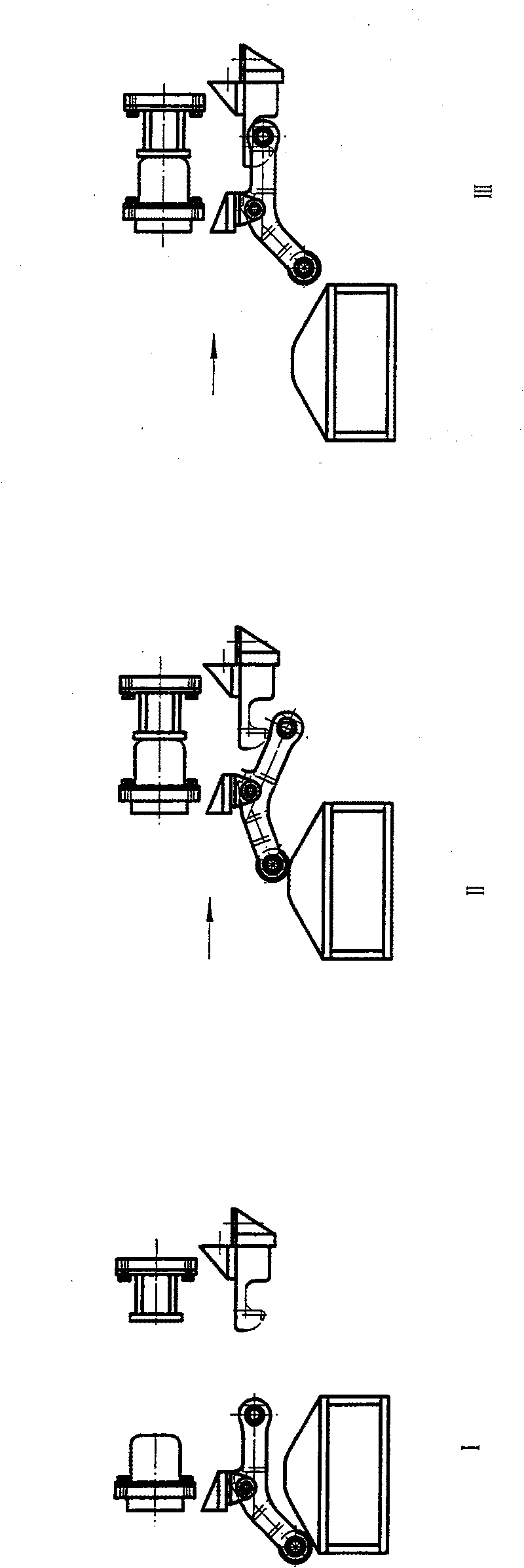

[0016] This system generally consists of a hoist 1, a looper trolley 4, and a plurality of supporting trolleys 8 determined according to the length of the looper and the characteristics of the steel plate, between multiple evenly distributed supporting trolleys 8, the supporting trolley 8 and the looper trolley 4 is composed of an auxiliary trailer coupling device, the trailer coupling device consists of figure 1 And attached figure 2 The coupling hook 5 fixed on the supporting trolley 8 shown in the figure and the support 9 fixed on the adjacent supporting trolley 8 and the lever type weight 6 hinged thereon and the decoupling device 7 fixed on the foundation, And the rubber buffer device that is installed between the material support trolley 8 constitutes in order to reduce the bump. The rubber buffer device wherein is made up of rubber buffer 2 and collision block 3: lever type weight 6 is made of roller cover A10, swing frame 11, roller cover B12.

[0017] When the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com