Continuous hot dip galvanizing zinc liquid aluminium content adjusting method

An adjustment method, hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems affecting the quality, performance and cost of coating products, and large fluctuations in aluminum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

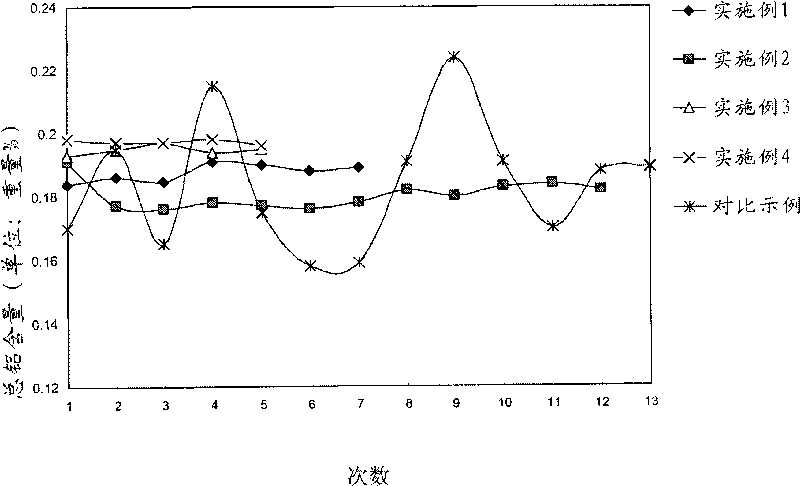

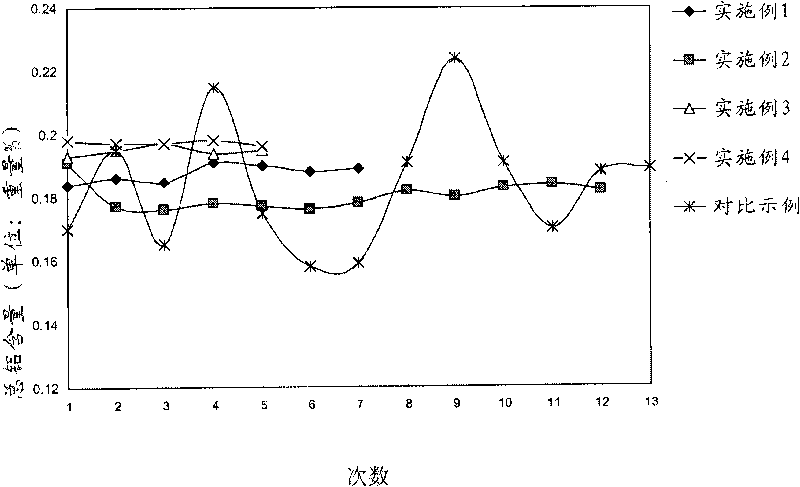

Embodiment 1

[0021] The continuous hot-dip galvanizing unit continuously produces strip steel with a specification of 1100mm×0.6mm and a coating weight of 120g / m 2 (Double-sided) galvanized products, the weight of the zinc bath in the zinc pot is about 176 tons, and the chemical analysis method is used to detect the total aluminum content in the zinc bath. It is tested every 4 hours during the production process, and the zinc bath level remains unchanged. as the benchmark. During the continuous production process, the unit maintains the zinc liquid level by adding zinc ingots, and the weight of each zinc ingot is about 1000kg. The initial detection of the total aluminum content in the zinc liquid was 0.175%, and the zinc liquid level was maintained by adding 6 main zinc ingots ①. Detect again by chemical analysis method and know that the total aluminum content in the zinc liquid is 0.186%, add 1 main zinc ingots ① and 4 main zinc ingots ② again, to keep the zinc liquid level. The third t...

Embodiment 2

[0024] The continuous hot-dip galvanizing unit continuously produces strip steel with a specification of 1100mm×0.5mm and a coating weight of 200g / m 2 (Double-sided) galvanized products, the weight of the zinc bath in the zinc pot is about 176 tons, the total aluminum content in the zinc bath is detected by chemical analysis, and it is tested every 4 hours during the production process, with the zinc bath level unchanged as the benchmark . The unit maintains the zinc liquid level by adding zinc ingots during the continuous production process, and the weight of each zinc ingot is about 1000kg. The initial detection of the total aluminum content in the zinc liquid was 0.191%, and the zinc liquid level was maintained by adding 1 main zinc ingot ① and 8 main zinc ingots ②. The total aluminum content in the zinc solution was detected by chemical analysis again to be 0.177%. Since then, 8 main zinc ingots have been added, and the total aluminum content in the zinc liquid has been ...

Embodiment 3

[0026] The continuous hot-dip galvanizing unit continuously produces strip steel with a specification of 1100mm×1.0mm and a coating weight of 200g / m 2(Double-sided) galvanized products, the weight of the zinc liquid in the zinc pot is about 176 tons, and the total aluminum content in the zinc liquid is detected by chemical analysis. It is tested every 4 hours during the production process, and the zinc liquid level is constant. benchmark. The unit maintains the zinc liquid level by adding zinc ingots during the continuous production process, and the weight of each zinc ingot is about 1000kg. The initial detection of the total aluminum content in the zinc solution was 0.193%. During this period, 2 main zinc ingots ① and 16 main zinc ingots ② were added according to the weight ratio of 1:8, and the total aluminum content was tested 3 times, and the total aluminum content was 0.193%, 0.195%, and 0.197% respectively. Then add 10 main zinc ingots ② and detect the total aluminum c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com