Variable timing system oil-way of minicar engine cylinder body assembly

A technology for engine cylinders and microcars, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as pressure oil leakage, complex process, and large chain motion noise, and achieve reduced starting noise, reduced motion noise, The effect of simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

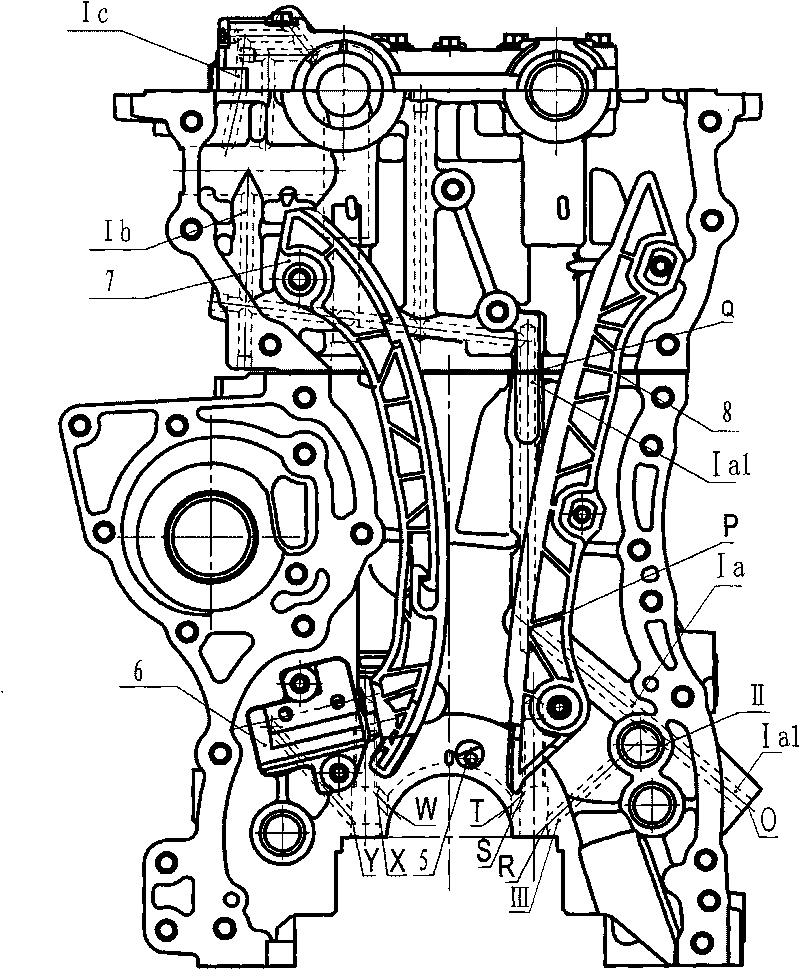

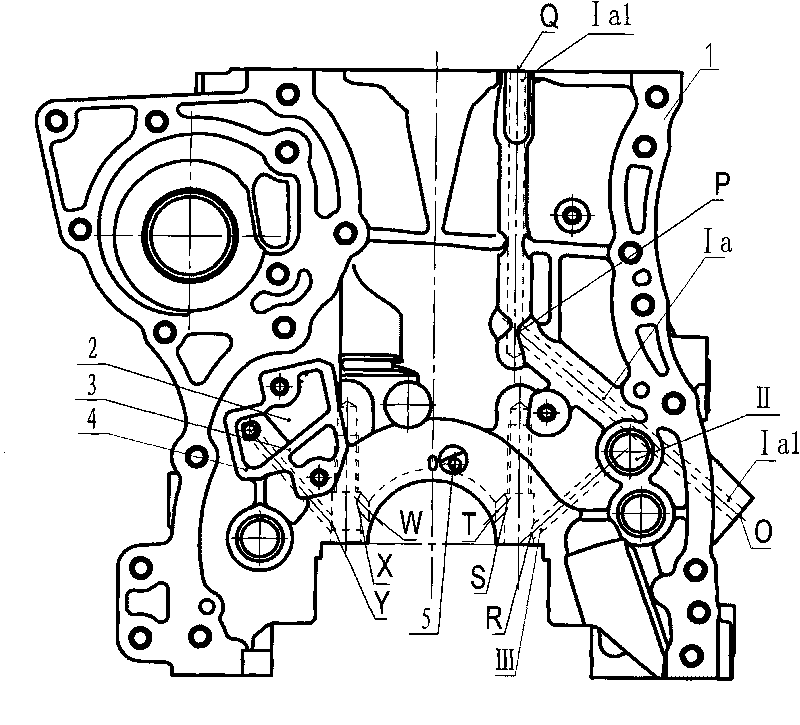

[0028] The utility model relates to an oil circuit of a variable timing system of a microcar engine block assembly.

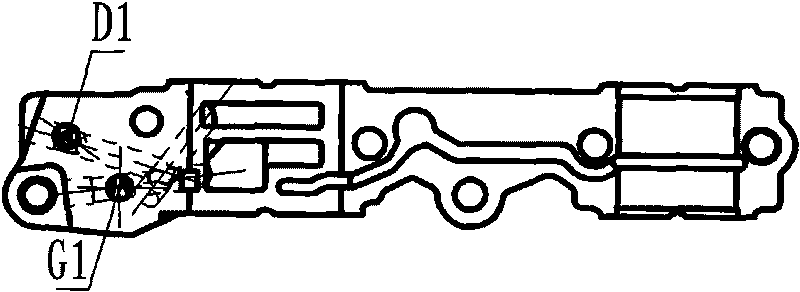

[0029] Such as figure 1 As shown, the variable timing system oil circuit of the microcar engine block assembly includes a VVT oil circuit and a hydraulic tensioner oil circuit, and the VVT oil circuit includes a VVT oil circuit built in the cylinder body Ia and the VVT oil passage Ib built in the cylinder head body and the VVT oil passage Ic located in the first camshaft bearing cap, the VVT oil passage I built in the cylinder body is connected by the main oil passage II and the points O and P The VVT oil passage Ia1 of the cylinder body between point Q and point Q is formed, and at point Q it communicates with the VVT oil passage Ib built in the cylinder head body, and the direction of the oil passage is: main oil passage II → point P → point Q; The hydraulic tensioner oil passage III is composed of the main oil passage II and the oil passage conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com