Staggered positioning combination piston ring

A combined piston and staggered technology, applied in the field of piston rings, can solve problems such as engine power drop, engine damage, and increased fuel and lubricating oil consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

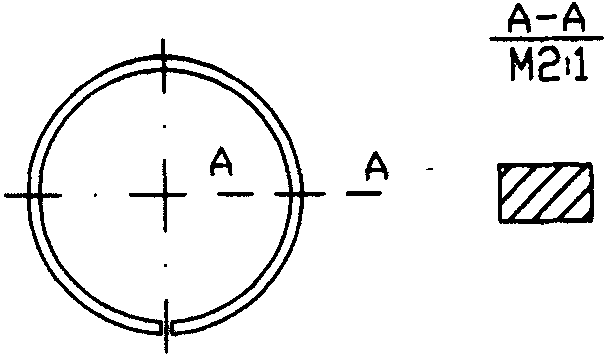

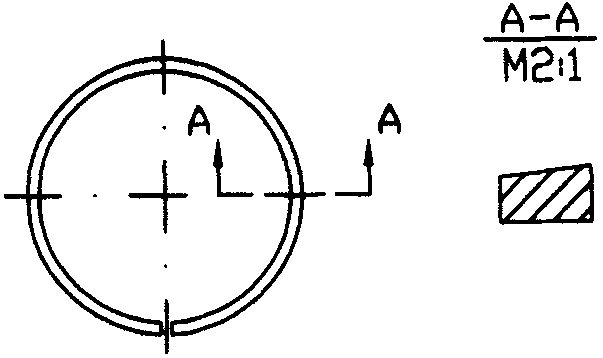

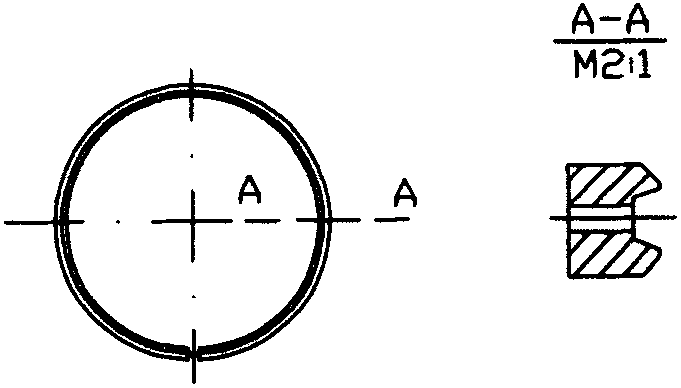

Image

Examples

Embodiment 1

[0018] Embodiment 1 Staggered positioning combined gas ring, the main ring is a rectangular gas ring, and the secondary ring is a steel ring, see Image 6 . Replace the existing rectangular air ring ( figure 1 ) Process a stepped ring groove on the outer side of the rectangular ring according to the design requirements, drill a small hole close to the inner circular surface of the step at about 30° on the stepped ring groove surface as shown in the figure, install the pin, and then place the steel sheet ring( Figure 5 ) Align the arc notches at both ends of the opening with the pins and assemble. When using and installing, the stepped ring groove and the steel sheet ring are on the lower side of the piston gas ring groove.

Embodiment 2

[0019] Embodiment 2 Staggered positioning combination gas ring, the main ring is a wedge-shaped gas ring, and the secondary ring is a steel ring, see Figure 7 . Insert the existing wedge-shaped gas ring ( figure 2 ) Process a stepped ring groove on the outside of the wedge-shaped ring plane according to the design requirements, and the rest are the same as in embodiment 1.

Embodiment 3

[0020] Embodiment 3 Staggered positioning combined oil ring, the main ring is a spiral spring oil ring, and the secondary ring is a steel sheet ring, see Figure 8 . Put the current spiral support spring oil ring body ( Figure 4 ) According to the design requirements, a stepped ring groove is processed on the outer surface of the ring body. On the solid part of the stepped ring groove surface at 25°-50° as shown in the figure, a small hole is drilled close to the inner circular surface of the step, and installed Pin, and then the steel ring ( Figure 5 ) Align the arc notches at both ends of the opening with the pins and assemble. When using and installing, the stepped ring groove and the steel sheet ring are on the upper side of the piston oil ring groove.

[0021] The advantages of staggered positioning combined piston rings are:

[0022] 1. The technology is novel, the structure is unique, the design is scientific, and it is the first at home and abroad.

[0023] 2. E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com