Device and method suitable for monitoring elevation change of bearing of turbo generator set

A technology for steam turbine generator set and change monitoring, which is applied to measurement devices, fluid devices, instruments, etc., and can solve the requirement of vertical float movement flexibility, many sensors, measurement devices, and analysis instrument channels, and test devices and Problems such as the difficulty of fixing the bearing seat surface to achieve the effect of satisfying the bearing elevation monitoring, expanding the monitoring range and convenient testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

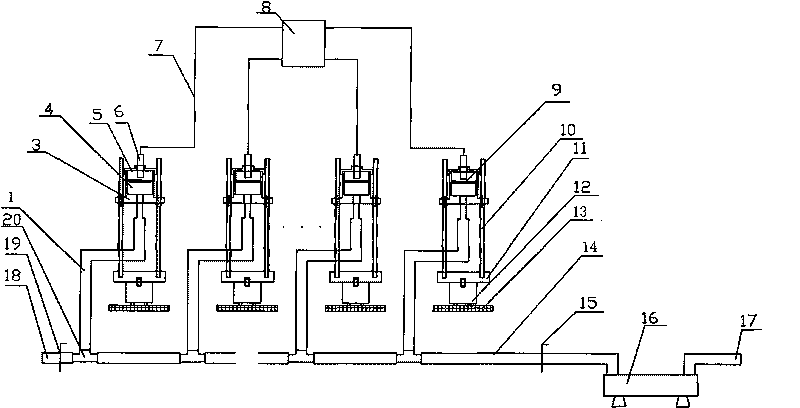

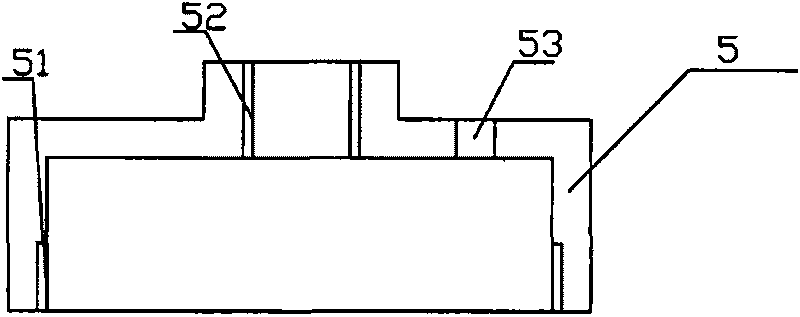

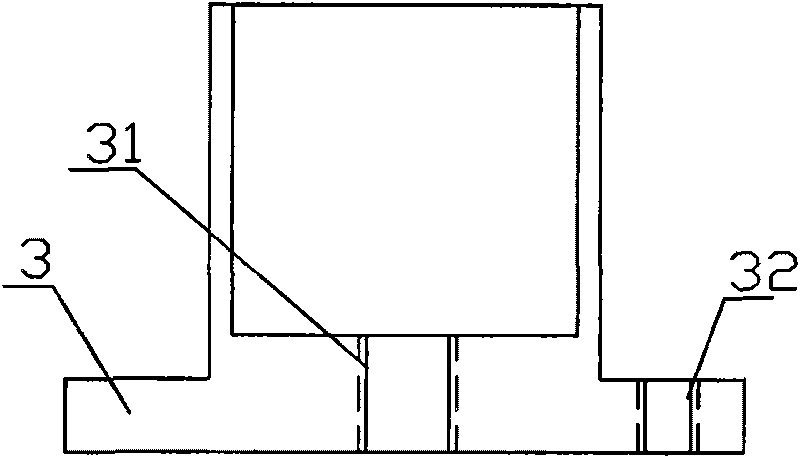

[0037] like figure 1 As shown, the present invention is applicable to the monitoring device of the bearing elevation of the steam turbine generator set, which includes a connecting pipe network, a data acquisition device 8, and a test device. On the bearing housing 13, each test device is connected to the main pipeline through the corresponding sub-pipe 1 and the tee 20, and the output end of each test device is connected to the input end of the data acquisition device 8 through the connection line 7. The test device comprises a cup 4, a cup bottom platform 3, a device base 11 and an eddy current sensor 6; the cup bottom platform 3 is provided with three screw holes 32, 33, 34, such as image 3 , Figure 4 As shown, the cup bottom platform 3 is connected to the device base 11 through three screw rods 10, and the cup 4 is connected to the branch pipe 1 through the threaded hole 31 provided at the bottom. The device base 11 is connected to the magnetic base 12 by screws, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com