Flexible ruler for controlling mansonry horizontal seam of coke oven refractory material

A technology of refractory materials and horizontal joints, applied in the direction of measuring scales, movable marks, measuring point marks, etc., can solve the problems of too large ash joints, difficult to reach, and difficult to guarantee the quality of the middle wall masonry, and achieve easy portability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

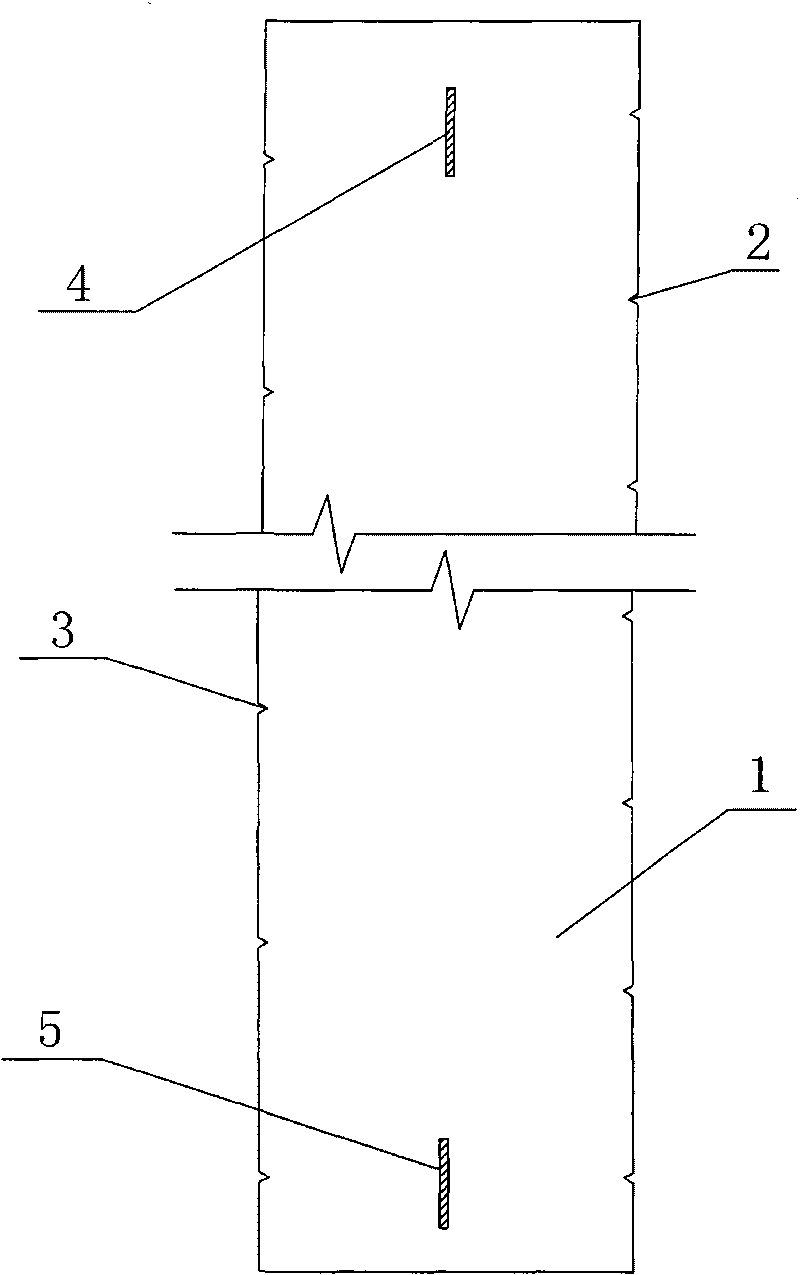

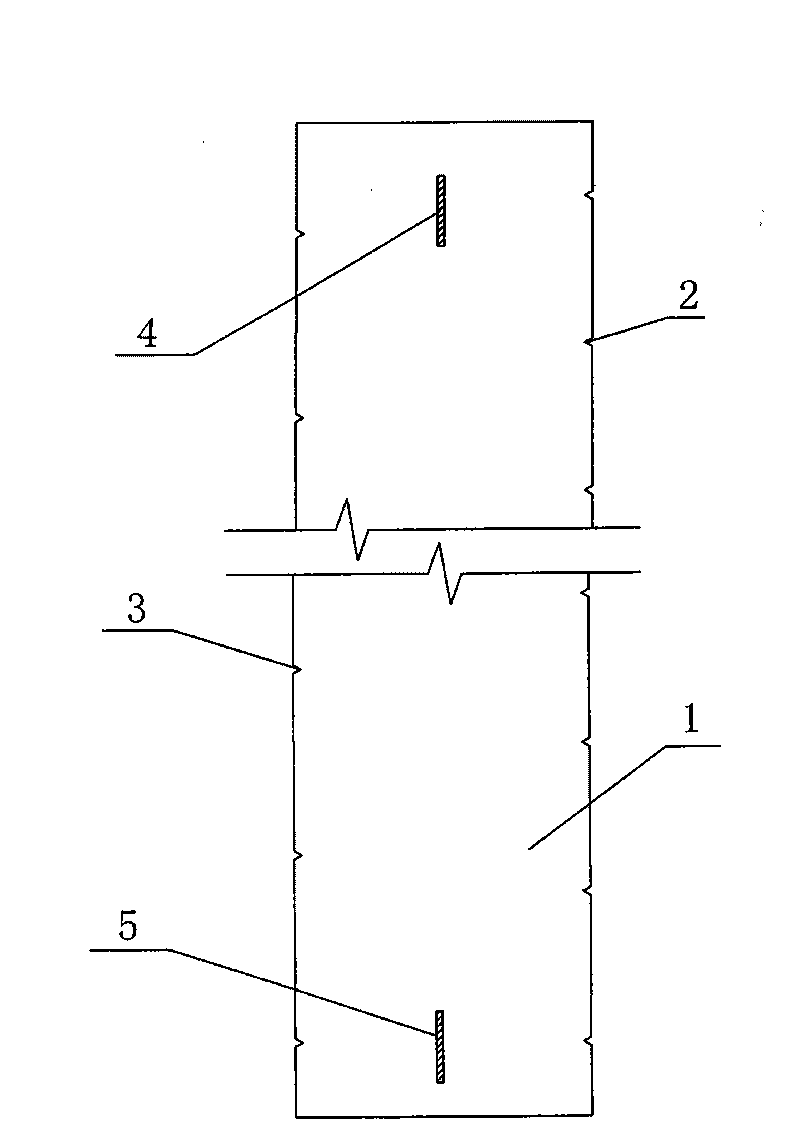

[0011] The coke oven refractory masonry horizontal joint control flexible scale provided by the present invention, such as figure 1 Shown: it is a long strip-shaped straightedge 1 made of plastic, and a plurality of evenly distributed reference knife edges for the pull wires of the regenerator wall 2 and the pull wires of the combustion chamber wall are respectively provided on both sides of the length direction With reference knife edge 3, in the middle of the reference knife edge 2 for the backguy of the regenerator wall and the reference knife edge 3 for the combustion chamber wall backguy at the uppermost end in its length direction, an upper notch 4 for fixing the ruler on the burner head is provided. The bottom notch 5 for fixing the ruler on the burner is arranged in the middle of the reference knife edge 2 for the backguy of the regenerator wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com