Method for sampling from long-axle workpieces by high frequency quenching metallographic examination

A metallographic inspection and high-frequency quenching technology, applied in the field of high-frequency quenching metallographic inspection sampling, quenching metallographic inspection sampling, can solve problems such as troublesome inspection cycle, workpiece damage, waste, etc., to achieve short sampling cycle, reduce waste and The effect of loss, convenience of sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

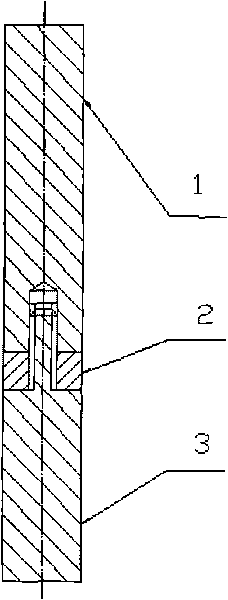

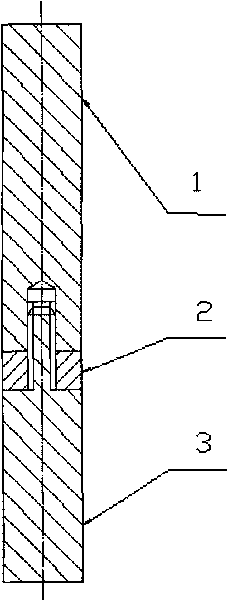

[0009] The workpiece sample (2) is tightly installed together through the internal and external threads between the upper aluminum rod (1) and the lower aluminum rod (3). The dimensions of the three after installation are exactly the same as those of the workpiece to be quenched. The material of the workpiece sample (2) is exactly the same as that of the workpiece to be quenched. Under the same process parameters, the combination of the above three is installed on a medium-high frequency machine tool. After quenching according to the specified process and parameters, remove the The workpiece sample (2), its metallographic examination, goes to find the quality problem of batch workpiece.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com