Low-volatility corrosion testing device

A corrosion test and low-volatility technology, which is applied to measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of large liquid backflow resistance, inability to form stable backflow, and inability to form backflow liquid, etc., to reduce escape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

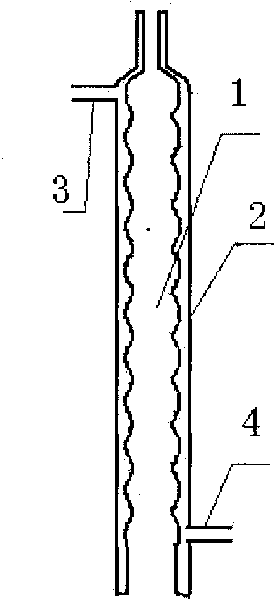

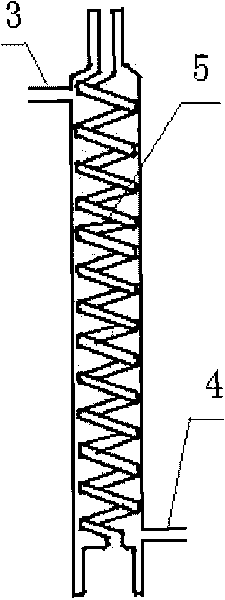

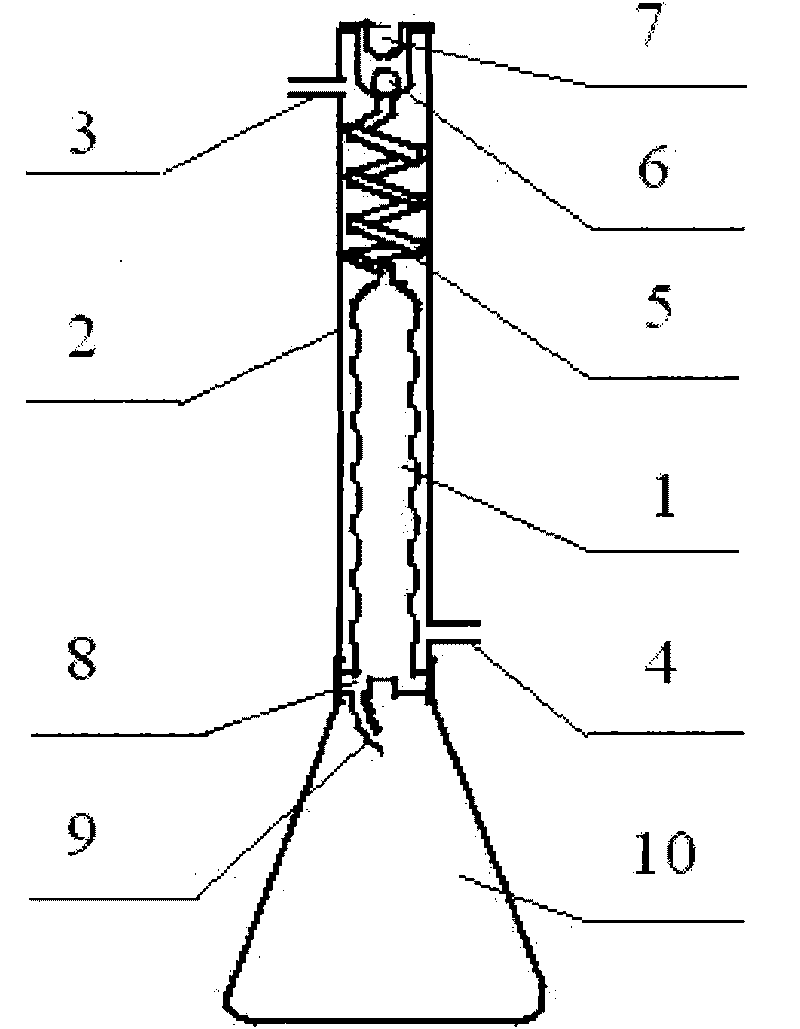

[0021] Such as image 3 A low-volatility corrosion test device shown includes a conical flask 10, a cooling inner tube installed on the flask 10, the lower part being a string tube 1 and the upper part being a spiral tube 5, and a cooling outer tube outside the cooling inner tube. Pipe 2, the upper and lower parts of the cooling outer pipe 2 are respectively provided with a cooling water outlet pipe 3 and a cooling water inlet pipe 4; 2 are connected together, and the pipe wall at the top of the spiral pipe 5 is connected with the cooling outer pipe 2; a hollow glass ball 6 is placed at the nozzle of the top of the spiral pipe 5, and a test tube-shaped hollow plug 7 is arranged on the top of the hollow glass ball 6 for cooling. The outer pipe 2 is slightly higher than the spiral pipe 5 to ensure that the hollow pipe plug 7 can be plugged into the cooling outer pipe 2; The ring-shaped right-angle folded plate is formed, and a diversion pipe 9 is connected to the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com