Process for making reflective fabric

A production method and technology of reflective cloth, applied in textile decoration, textile and papermaking, etc., can solve the problems of increased manufacturing difficulty, poor adhesion, and low economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Since the prior art usually encounters problems such as poor adhesion or difficulty in manufacturing when making reflective fabrics, the present invention proposes a method for producing reflective fabrics to produce reflective fabrics with good bonding strength, so that It can be widely used in clothes and other required accessories and industrial materials.

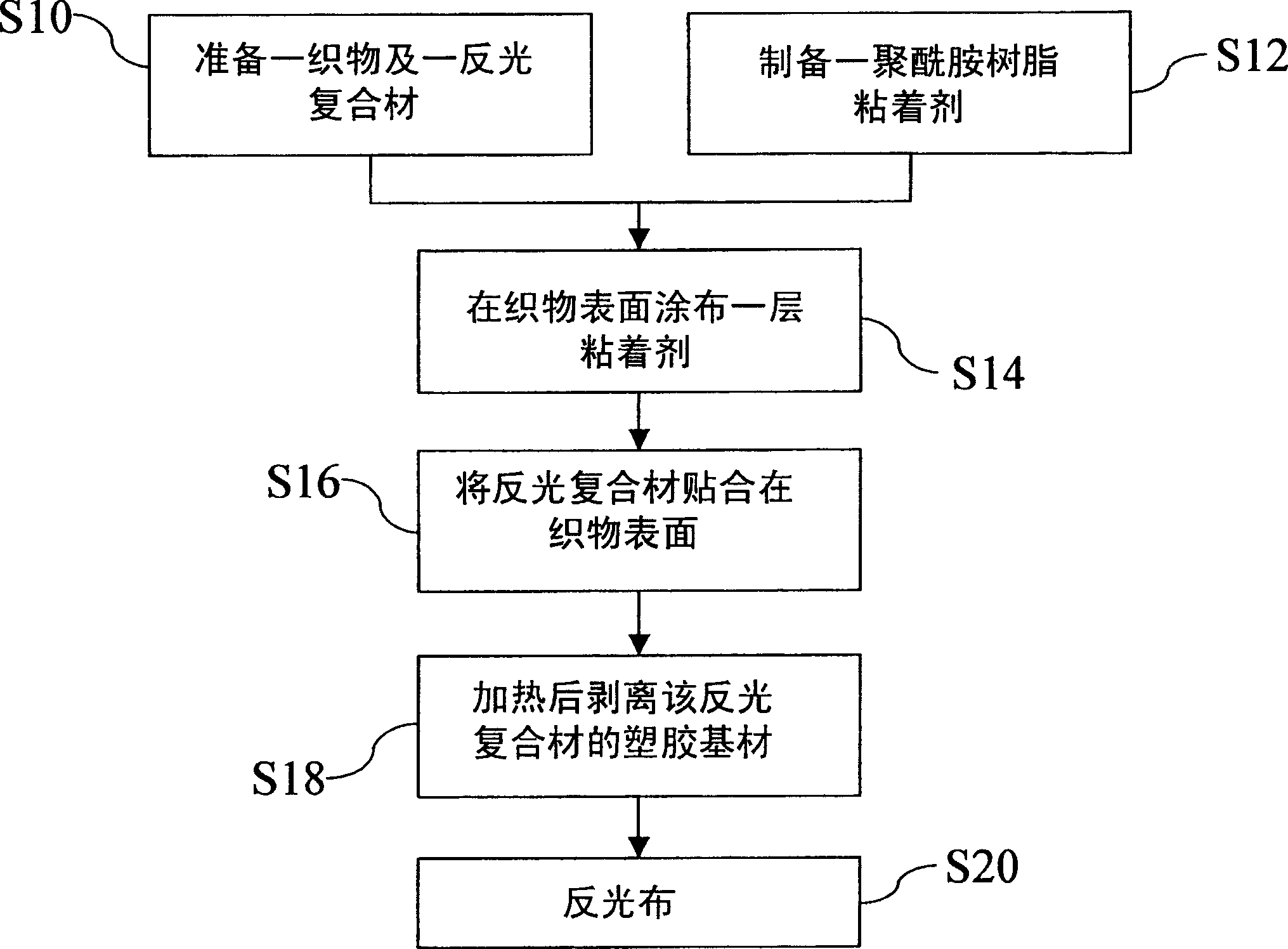

[0012] figure 1 For the present invention is making the schematic flow chart of reflective cloth, as shown in the figure, at first, prepare a fabric to be processed and a reflective composite material as shown in step S10, wherein, this reflective composite material is made of a plastic substrate and utilizes heat It is composed of reflective glass beads adhered to the plastic substrate by melting resin, and the fabric to be processed will not have restrictions on the types of fabrics. The types of fabrics used can be knitted fabrics, plain woven fabrics (WOVEN), horizontal grain (OTTOMAN), plaid (RIBSTOP), twil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com