Preparation method and apparatus for glass fiber filtering material

A glass fiber and filter material technology, which is applied in the field of filter materials, can solve the problems affecting the filter performance of glass wool felt and the deterioration of glue uniformity, and achieve the effect of small diameter, good uniformity and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

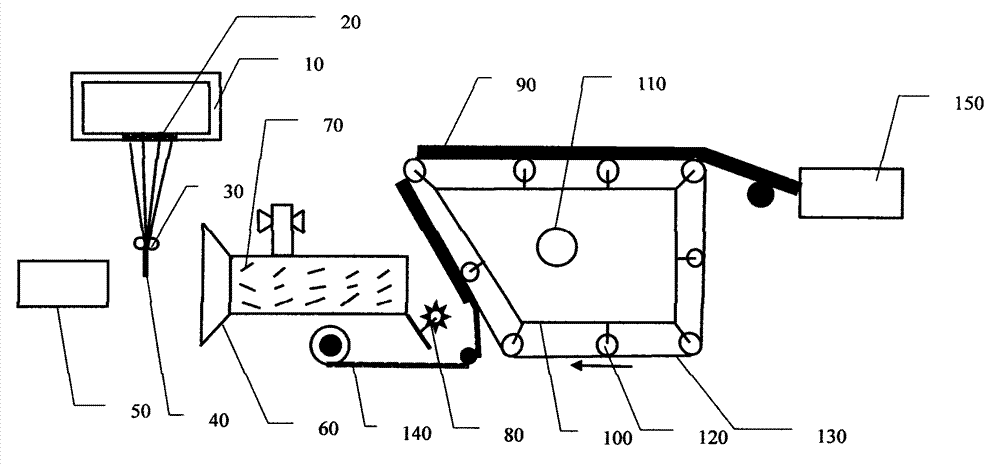

[0029] Such as figure 1 A device for preparing glass fiber filter material is shown, which includes: kiln 10, bushing plate 20, primary wire 30, rubber roller 40, combustion chamber 50, bell mouth cotton collection chamber 60, secondary wire 70, glue spraying tube 80, glass wool felt 90, cotton collecting box 100, negative pressure fan 110, conveyer 120, cotton collecting net 130, non-woven fabric 140, curing oven 150.

[0030] The flame ejected from the combustion chamber is a mixture of natural gas and air, the ratio is 3.5:1, the flame temperature is 950°C, the pressure is 0.025MPa, and the injection speed is 20m / s; the diameter of the glass fiber is 3μm, and the thickness of the glass wool felt is 10mm; the thickness of the non-woven fabric is 2mm, and its roller is under the cotton collecting box, bypassing the roller under the cotton collecting box and moving with the mesh belt; the curing temperature is 200°C, and the curing time is 4 minutes.

[0031] A kind of glass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com