High voltage wall bushing

A high-voltage wall-penetrating bushing and set technology, which is applied in the direction of pipes, pipes/pipe joints/pipes, electrical components, etc., can solve the problems of reducing mechanical strength and insulation performance, scratching and discharging, high processing accuracy and difficulty, and achieves improved Bond strength and stability, increase adhesive bond strength, good pressure equalization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

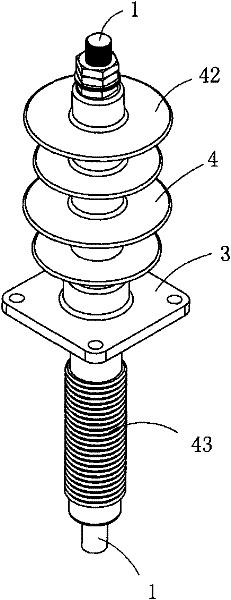

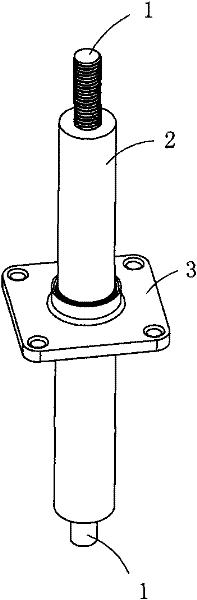

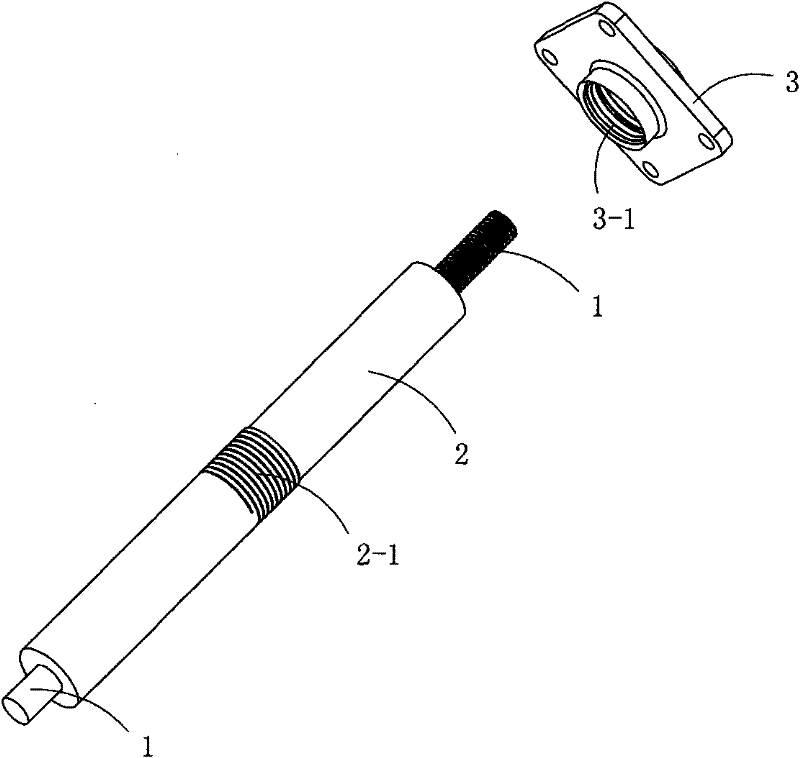

[0032] Figure 4 to Figure 9 A specific embodiment of the invention is shown in which, Figure 4 It is a schematic diagram of a three-dimensional structure of the present invention; Figure 5 yes Figure 4 A schematic diagram of a three-dimensional structure of the high-voltage wall bushing shown after removing the creep-increasing insulating layer; Figure 6 yes Figure 5 The exploded schematic diagram of the high-voltage wall bushing after removing the creep-enhancing insulation layer; Figure 7 yes Figure 4 A schematic diagram of the three-dimensional structure of the connecting flange in the high-pressure wall bushing shown; Figure 8 yes Figure 7 A schematic diagram of the three-dimensional structure of the connecting flange shown when viewed from another angle; Figure 9 yes Figure 7 Half-section view of connecting flange shown.

[0033] This embodiment is a kind of high-voltage wall-through bushing, see Figure 4 to Figure 6 , including a conductive rod 1, ...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, except that: the inner insulating layer 2 is provided with an external thread at the glued joint with the connecting flange 3).

Embodiment 3

[0047] This embodiment is basically the same as Embodiment 1, except that: the inner insulating layer 2 is provided with an annular groove at the glued joint with the connecting flange 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com